Moisture absorption humectant and method for preparing same

A humectant and hyaluronic acid technology, which is applied in the field of daily chemicals, can solve the problems that hyaluronic acid cannot meet the market needs, is difficult to collect and process, and the separation process is complicated, and achieves high moisture absorption and moisturizing performance, low cost, and moisture absorption and moisturizing performance. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

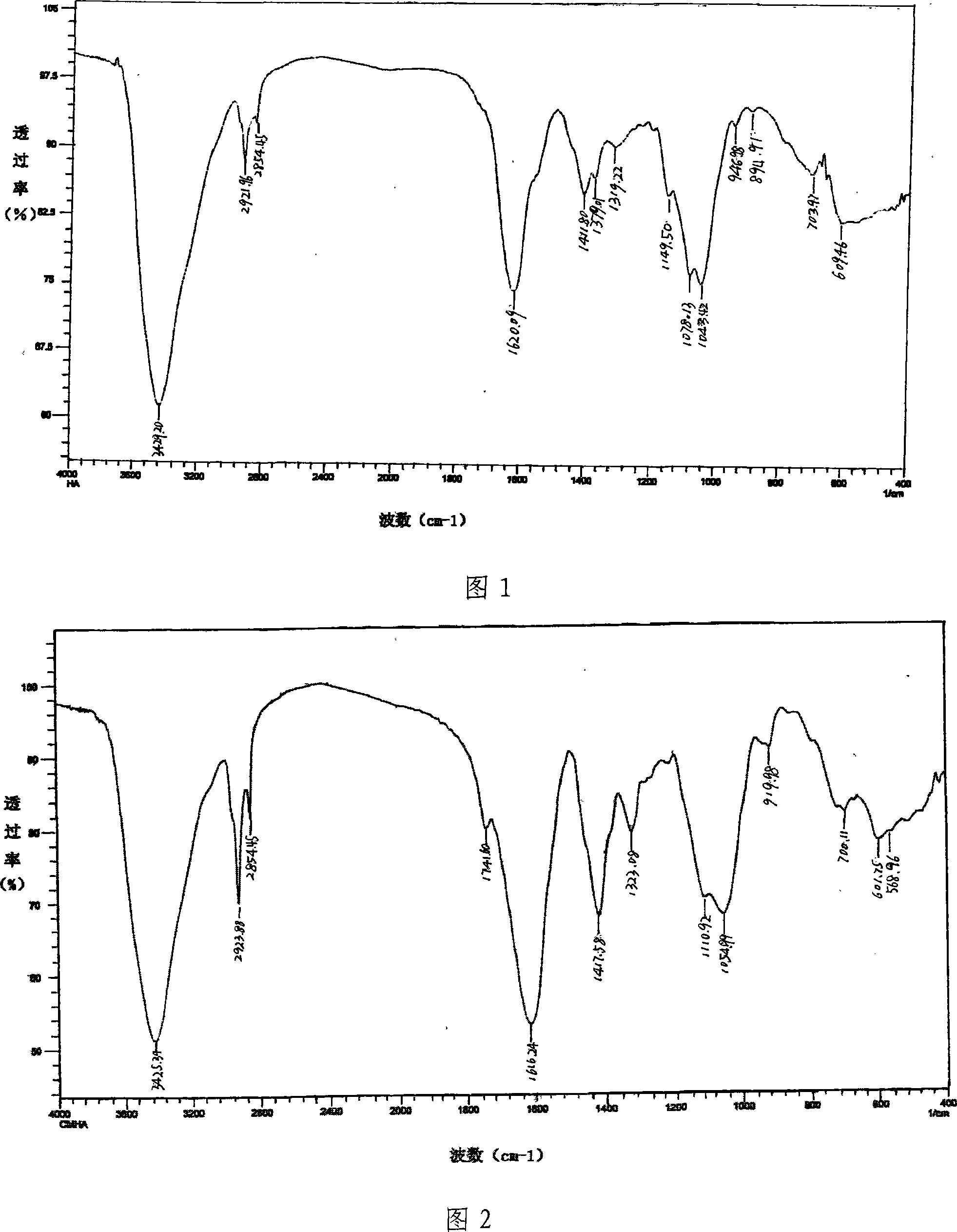

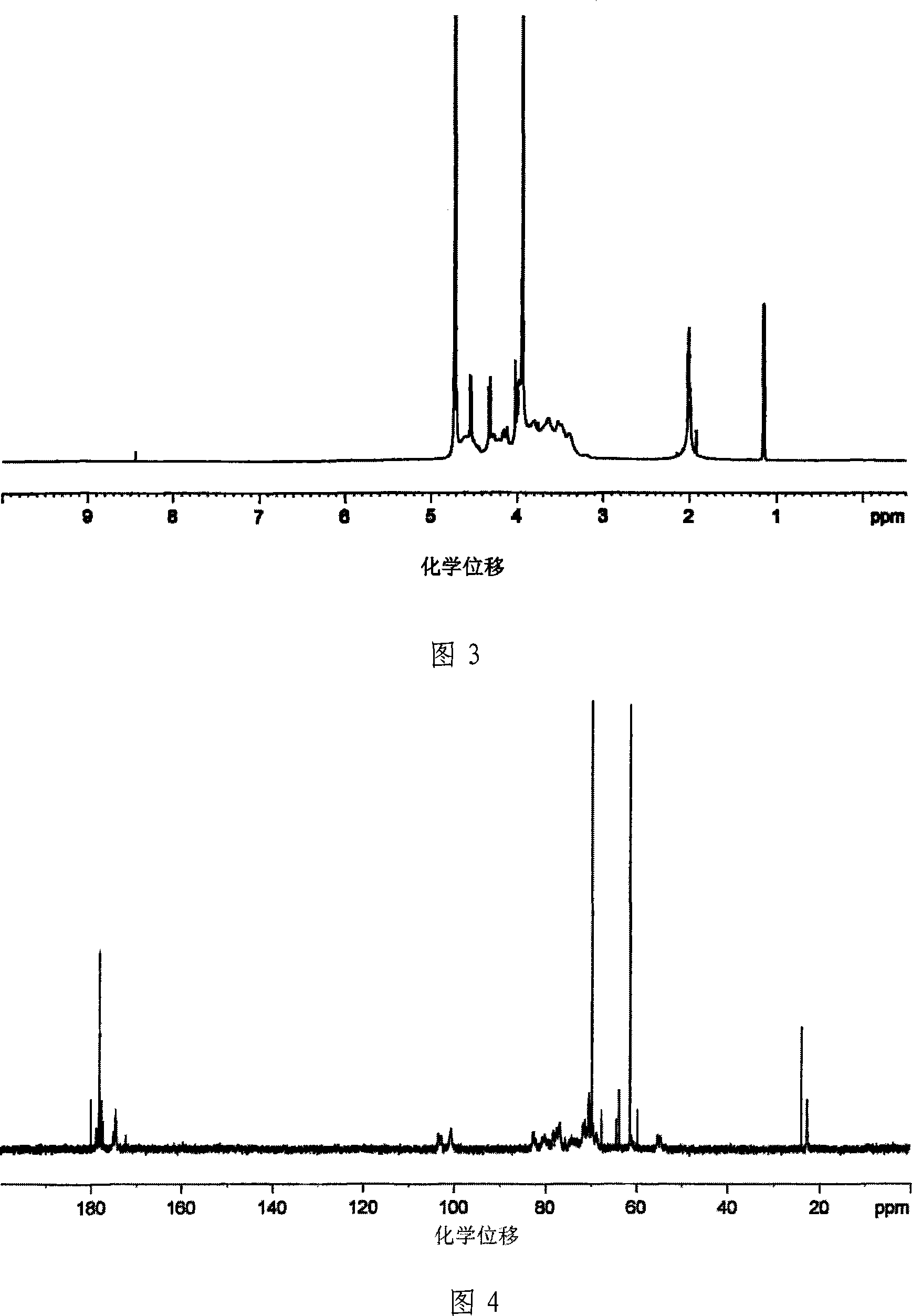

[0016] Preparation of carboxymethyl hyaluronic acid: add 2g of hyaluronic acid (see Figure 1) to 10mL of isopropanol, stir and swell at room temperature for 10min, then add 10mol / L NaOH solution in 6 times, 0.5mL each time, once every 4min, and add it for the last time. Stir for another 40 minutes to obtain alkaline hyaluronic acid, then add 2 g of solid chloroacetic acid in 4 times, once every 6 minutes, stir and react at 35°C for 5 hours after the addition, and filter with suction, then wash with 30 mL of methanol, and filter with suction. Dry at 50°C to obtain carboxymethyl hyaluronic acid (see Figure 2, Figure 3, Figure 4).

[0017] The prepared carboxymethyl hyaluronic acid is used as a hygroscopic moisturizing agent.

Embodiment 2

[0019] The difference from Example 1 is:

[0020] Preparation of carboxymethyl hyaluronic acid: Add 2g of hyaluronic acid to 40mL of isopropanol, stir and swell at room temperature for 40min, add 10mol / L NaOH solution in 6 times, 0.5mL each time, once every 4min, and stir for 40min after the last addition , to obtain basic hyaluronic acid, then add 3 g of solid chloroacetic acid in 6 times, once every 4 minutes, stir and react at 75 ° C for 1 h after the addition, filter with suction, then wash with 30 mL of methanol, filter with suction, and dry at 70 ° C Dry to obtain carboxymethyl hyaluronic acid.

Embodiment 3

[0022] The difference from Example 1 is that the hyaluronic acid swollen by an alkaline isopropanol solution with a molar mass ratio of 1:5 reacts with chloroacetic acid at 50°C in an excess of alkaline isopropanol solution 3h, and then washed with methanol, suction filtered, and dried at 60°C to obtain carboxymethyl hyaluronic acid. Among them, chloroacetic acid was added into hyaluronic acid in 6 times with an interval of 5 minutes. The hyaluronic acid swollen by the alkaline isopropanol solution is to stir and swell the hyaluronic acid through the alkaline isopropanol solution at room temperature for 30 minutes, wherein the amount of the alkaline isopropanol solution is 10 times the mass volume of the hyaluronic acid , the alkaline isopropanol solution is isopropanol with a volume ratio of 20:3 and a concentration of 10mol / L sodium hydroxide, wherein the sodium hydroxide is added to the isopropanol in 6 times with an interval of 6 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com