Heat transmission belt of household air conditioner and its special structure during application

A technology of heat transfer belt and air conditioner, which is applied in the field of heat transfer belt, can solve the problems of heat transfer performance attenuation, heat dissipation performance attenuation, and low heat exchange efficiency, so as to improve heat exchange capacity and effectiveness, eliminate heat exchange capacity attenuation, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

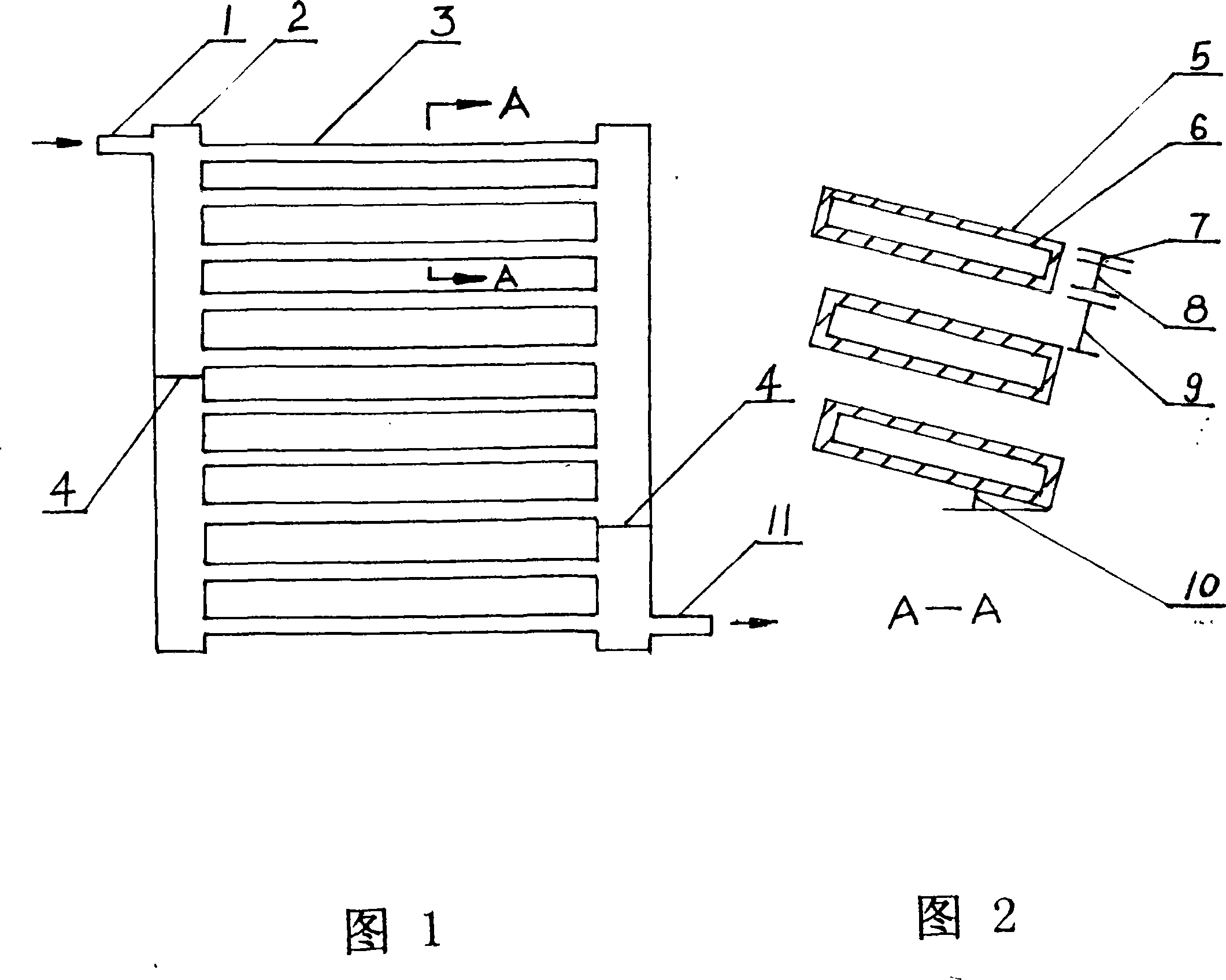

[0017] In the figure, 1 is the refrigerant inlet pipe, 2 is the header, 3 is the flat belt, 4 is the spacer, 5 is the cavity frame, 6 is the cavity opening, 7 is the cavity thickness, 8 is the cavity opening height, and 9 is the flat With net spacing, 10 is the included angle, 11, the refrigerant outlet pipe.

[0018] This embodiment is an embodiment of the present invention applied to a household air conditioner condenser: 5 in the figure is the cavity frame of the flat belt, 6 is the opening of the flat belt, 7 is the thickness of the cavity of the flat belt, and 8 is the height of the cavity of the flat belt. 9 is the flat belt net spacing. The high-temperature and high-pressure refrigerant gas from the compressor enters the header 2 through the refrigerant inlet pipe 1 on the header 2, flows through the flat belt 3 under the barrier of the diaphragm 4, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap