Shuttle type check valve

A check valve and shuttle type technology, applied in the field of one-way valves, can solve the problems of short service life, complex structure, leakage, etc., and achieve the effect of increasing selectivity and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

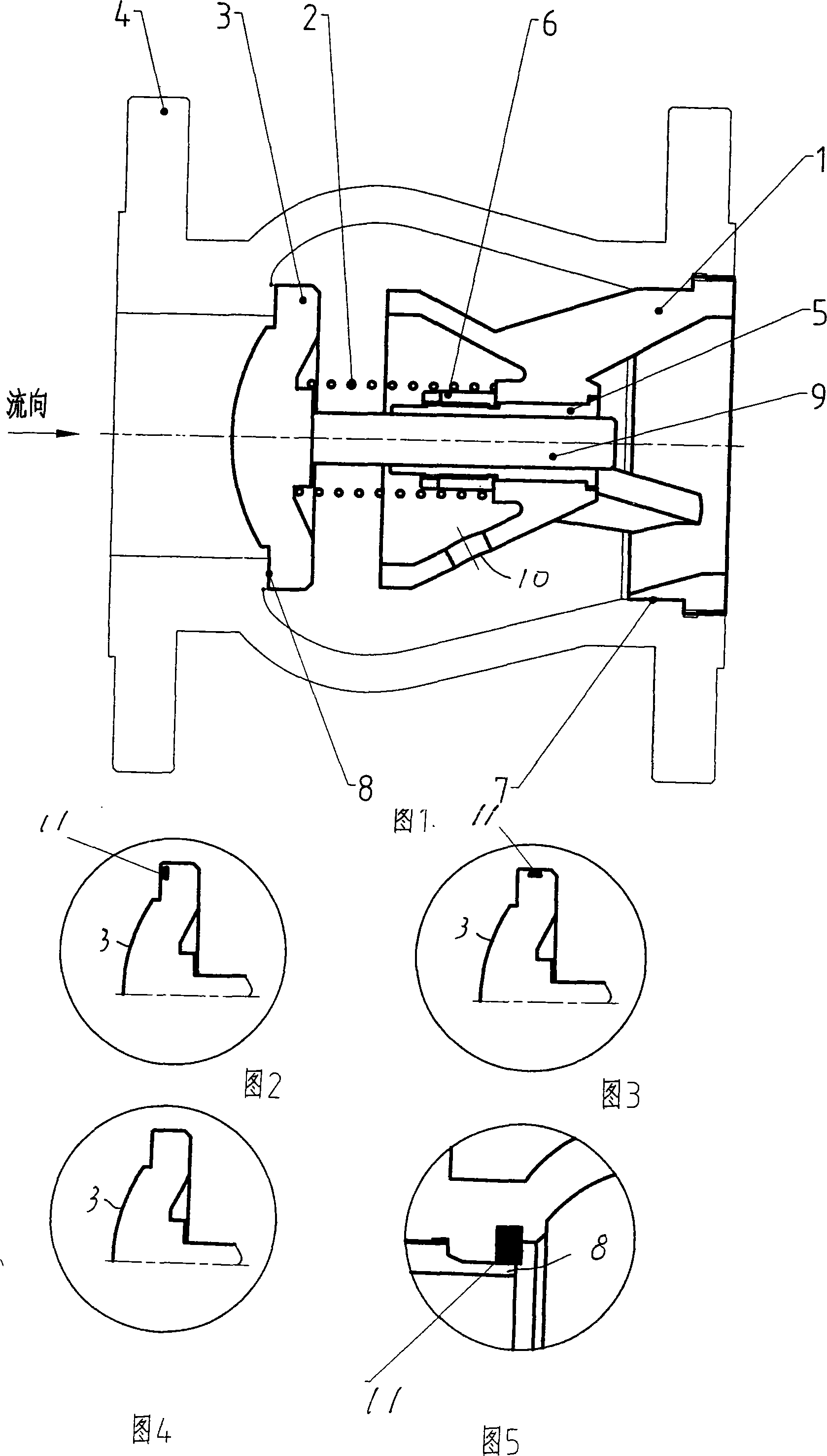

[0017] The inner cavity of the flange at the right end of the housing 4 is threadedly connected with the precision fitting ring 7, and the connection length is greater than 20mm. The valve sleeve 1 is integrated with the precision fit ring 7 and forms a closed cavity with the valve disc 3. In the cavity, a spring 2 is set on the valve shaft 9, and the valve shaft 9 is dynamically matched with the shaft sleeve 5 connected to the central hole of the valve sleeve 1. The precision fit section length between the shaft sleeve 5 and the valve shaft 9 is greater than 20 mm. A through hole 10 is arranged on the valve sleeve 1 . A lock nut 6 is arranged on the axle sleeve 5 . The sealing method between the valve seat 8 and the disc 3 can be selected as follows:

[0018] ① O-ring flexible seal on the disc end face;

[0019] ② O-ring flexible seal on valve disc cylindrical surface;

[0020] ③Metal hard seal on the disc end face;

[0021] ④ Metal hard seal on the end face of the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com