AI-based alloy sputtering target and process for producing the same

A technology of base alloy and sputtering target, which is applied in the field of Al-base alloy sputtering target and its preparation, can solve the problems of no proposal, high production cost, troublesome preparation method and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 3. The method for preparing an Al-based alloy sputtering target according to item 1 or 2, the method comprising:

[0039] preparing a dense body of Al-based alloy; then

[0040] forging the dense body of the Al-based alloy to obtain a slab; then

[0041] rolling the slab at a rolling temperature of 400 to 500°C, a reduction ratio of 5 to 15% per pass, and a total reduction ratio of 60 to 90%; and then

[0042] Heating is performed at a temperature in the range of 300 to 400°C for 1 to 2 hours.

[0043] 4. The method according to item 3, wherein said preparation of the dense body of the Al-based alloy comprises:

[0044] Al-based alloy preforms are prepared according to the spray forming method, and

[0045]Al-based alloy preforms are densified by means of densification.

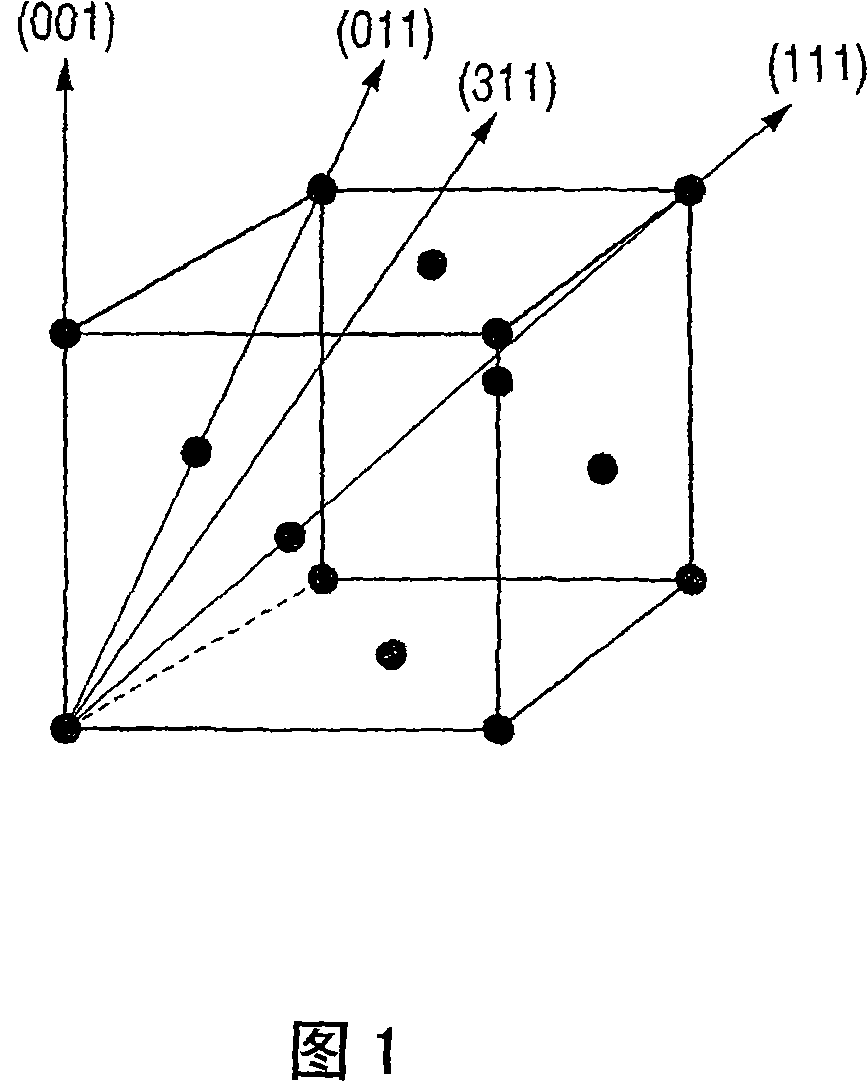

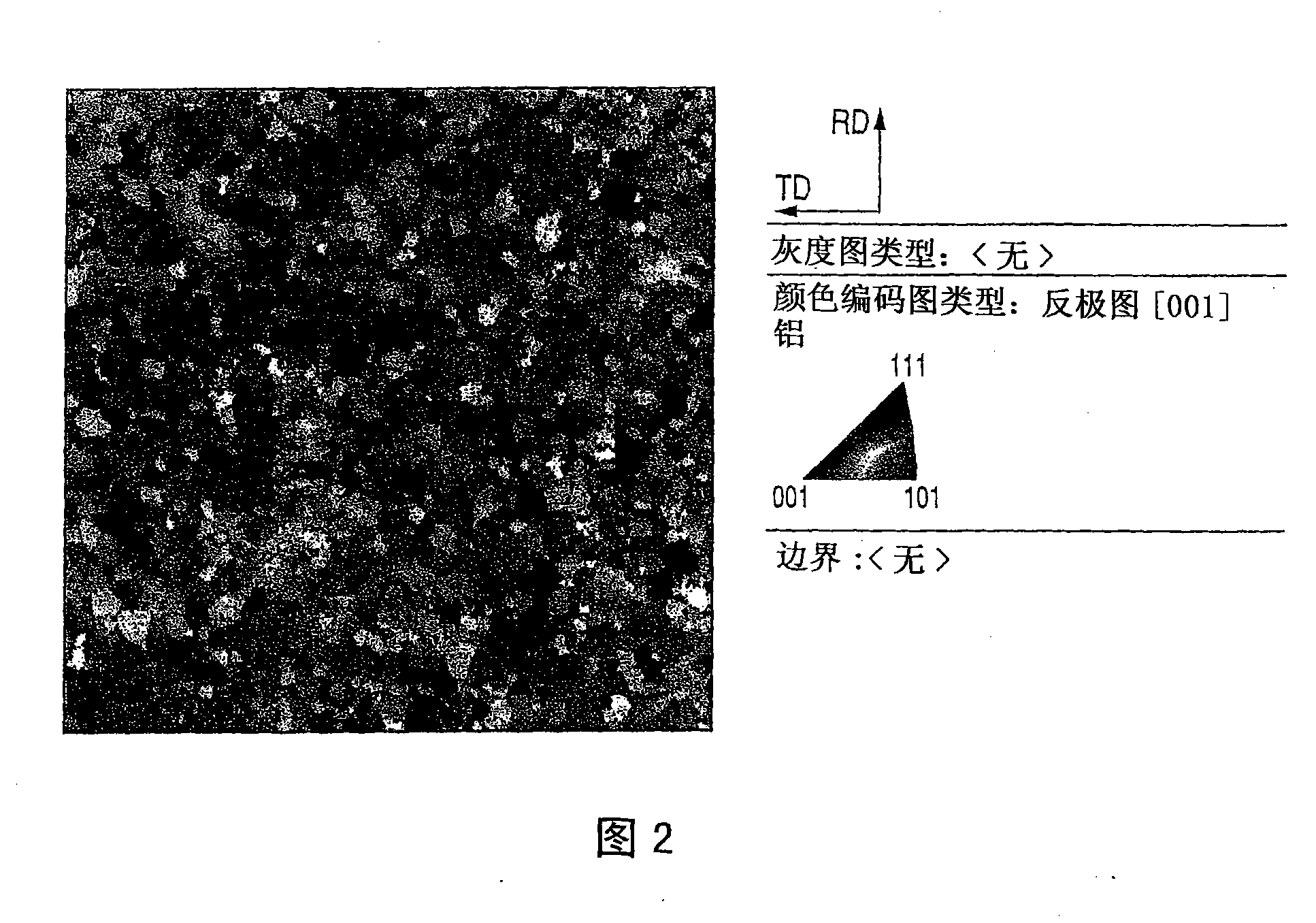

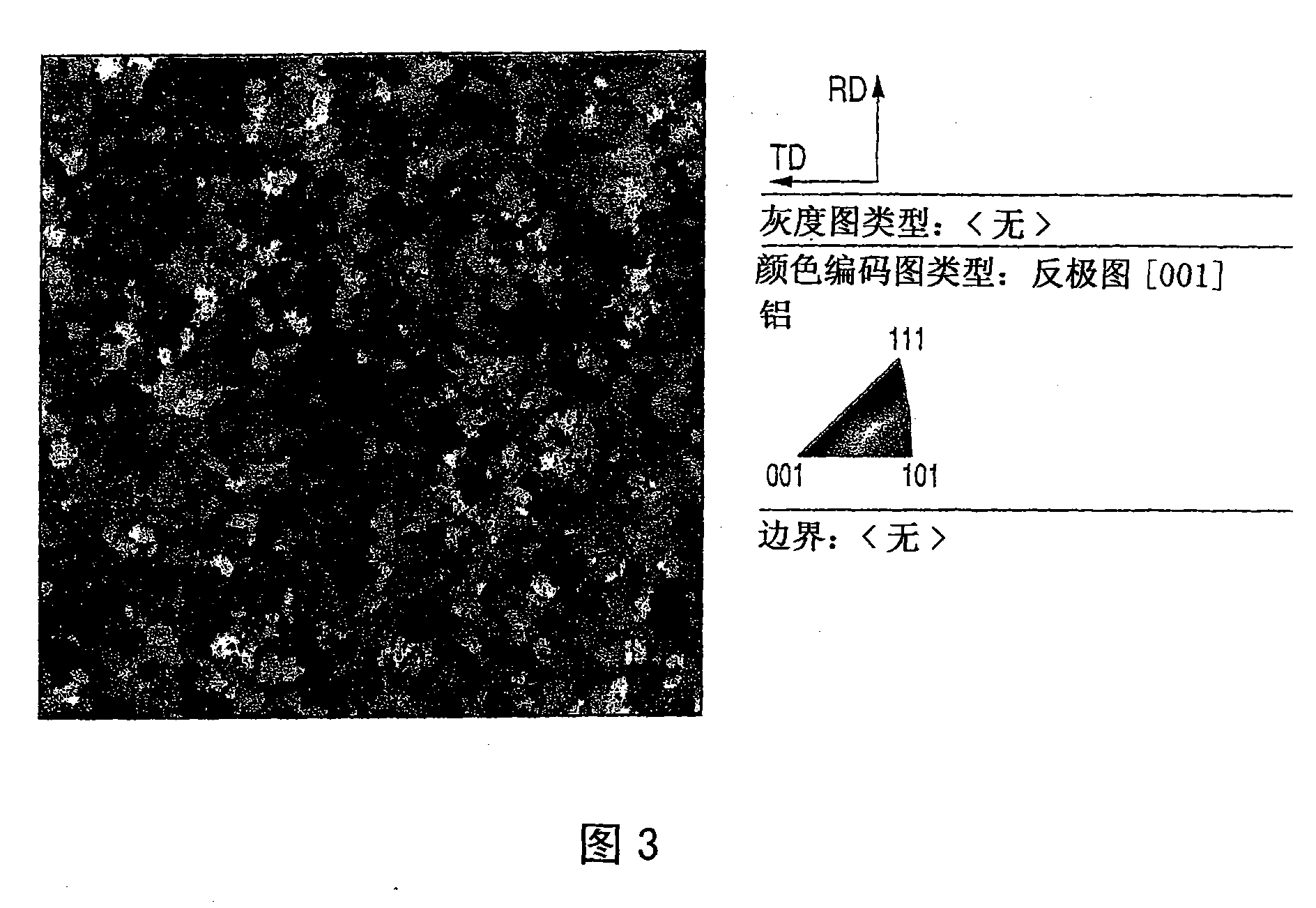

[0046] According to the Al-based alloy sputtering target of the present invention, since the crystallographic orientation in the normal direction of the sputtering surface is appropriately controll...

Embodiment 1

[0127] From Al-based alloys whose compositions are shown in Tables 1 and 2, Al-based alloy preforms (density: substantially 50 to 60%) were obtained according to the following spray forming method.

[0128] (Injection molding conditions)

[0129] Melt temperature: 1000°C

[0130] Gas / Metal Ratio: 6Nm 3 / kg

[0131] Spray distance: 1050mm

[0132] Gas atomizer outlet angle: 7°

[0133] Collector Angle: 35°

[0134] Subsequently, each preform obtained was sealed in a capsule, followed by degassing, and then densified with a HIP apparatus. The HIP treatment was performed at a HIP temperature of 550° C. for a HIP time of 2 hours at a HIP pressure of 85 MPa.

[0135] The Al-based alloy dense body thus obtained was forged under conditions of a heating temperature of 500° C. before forging, a heating time of 2 hours, and an upsetting ratio of 10% or less each time, thereby obtaining a slab (dimensions: thickness 60 mm, width 540mm and length 540mm).

[013...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com