Method and device for producing methanol with COREX fusion reduction furnace coal gas

A reduction furnace and methanol technology, applied in the field of metallurgical chemistry, can solve the problems of waste of resources, low utilization value, and increased cost of molten iron, and achieve the effects of low cost of molten iron, economical energy utilization, and improved energy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

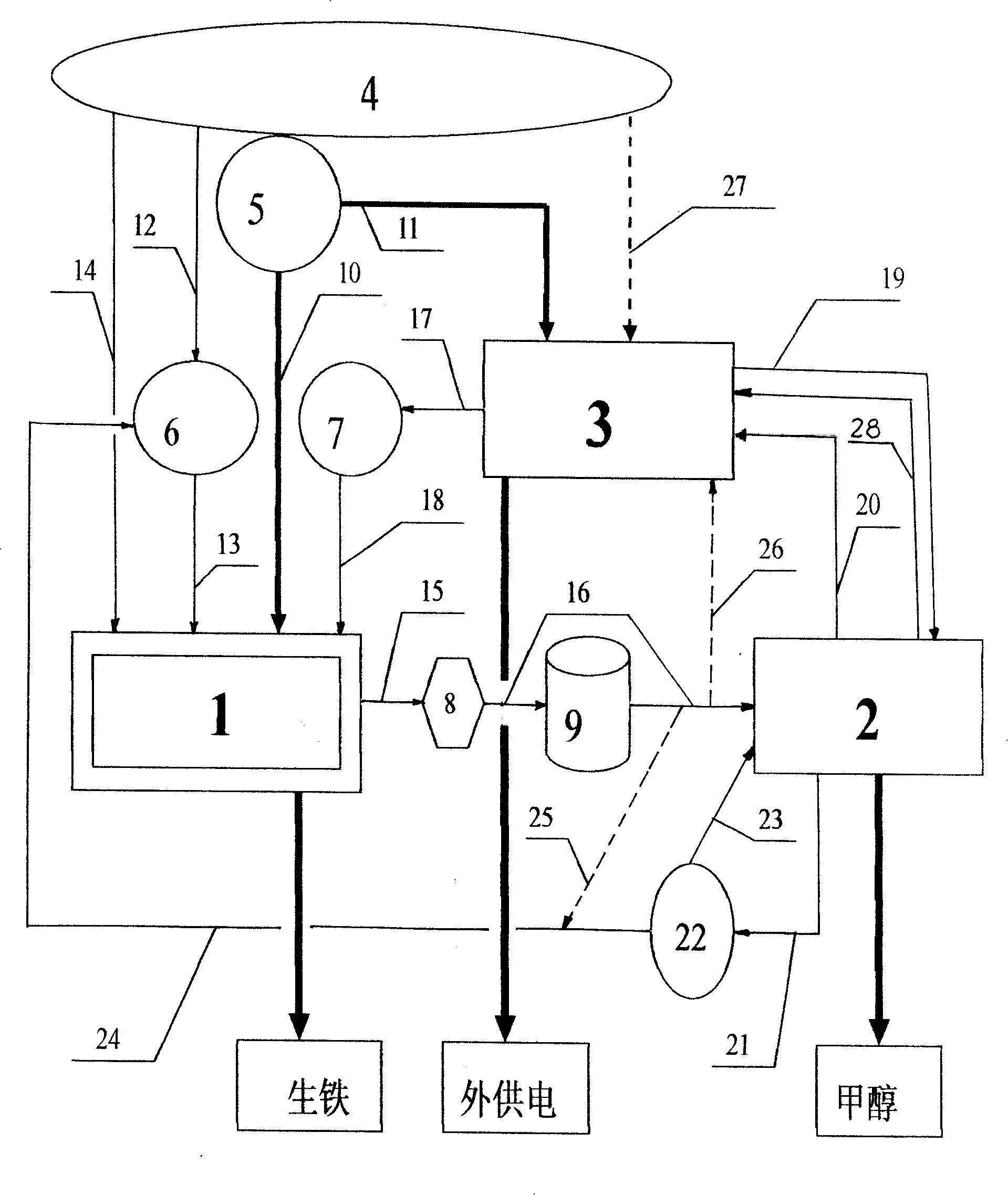

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0010] The lump ore from the raw material field 4 is sent to the COREX smelting reduction furnace 1 through the lump ore belt conveyor 14, and the fine ore is sent to the pellet plant 6 through the fine ore belt conveyor 12, and the pellets are sent to the pellet plant through the pellet belt conveyor 13 COREX smelting reduction furnace 1, the coal from the raw material field 4 is screened out by the screening section 5 and sent to the COREX smelting reduction furnace 1 through the lump coal belt conveyor 10, and the pulverized coal under the sieve is sent to the self by the pulverized coal conveyor belt conveyor 11 The pig iron produced by the thermal backup power station 3 and the COREX smelting reduction furnace 1 can be cast into iron blocks or used for steelmaking.

[0011] The by-product gas of the COREX smelting reduction furnace 1 is sent to the TRT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com