System and method for biomass fractional conversion co-production of oil and gas with solar heating

A solar heating and biomass technology, applied in the directions of products, educts, energy input, etc., can solve the problems of energy waste, increase CO2 emissions, etc., and achieve the effect of optimizing the energy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions and effects of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The following embodiments are only for illustrating the content of the present invention, and the invention is not limited to the following embodiments or examples. Simple changes made to the present invention by applying the concept of the present invention are all within the scope of protection of the present invention.

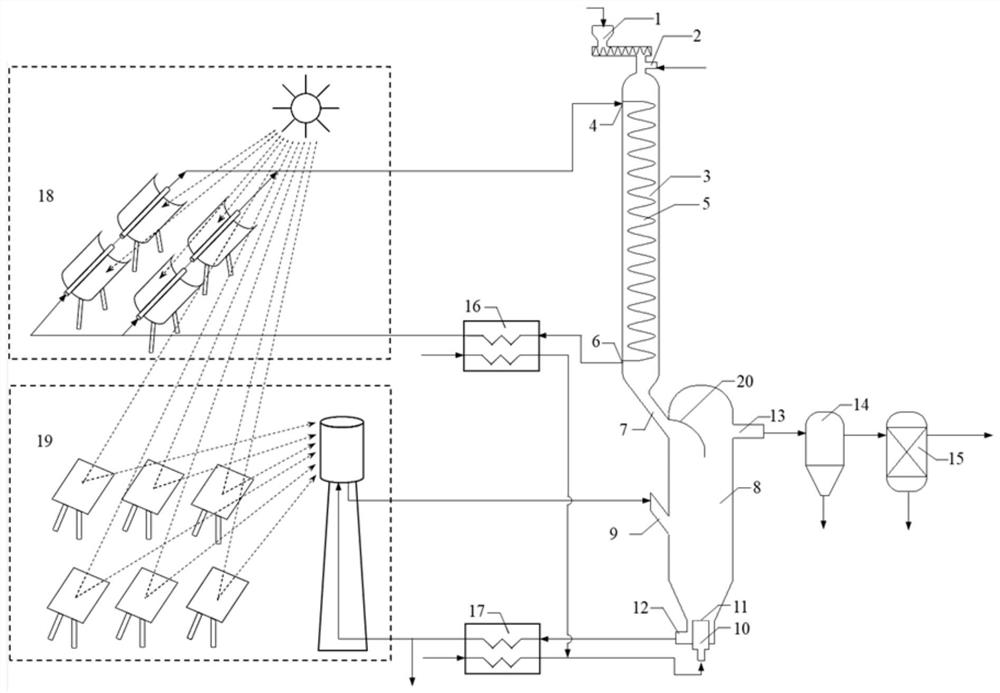

[0054] Such as figure 1 As shown, the biomass fractional conversion co-production oil and gas system of solar heating of the present invention includes a pyrolysis and gasification reaction unit, a solar heating unit and an oil and gas purification and separation unit; wherein,

[0055] Described solar heating unit comprises trough solar molten salt heating unit 18 and tower type solar biomass ash heating medium heating unit 19; Described trough solar molten salt heating unit 18 is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com