Wire cutting device for screw energy conserving lamp assembling production

A technology for cutting devices and energy-saving lamps, applied in the direction of shearing devices, shearing machine equipment, metal processing equipment, etc., can solve the problems of low work efficiency, time-consuming and laborious, etc., and achieve the effects of improved work efficiency, simple device structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

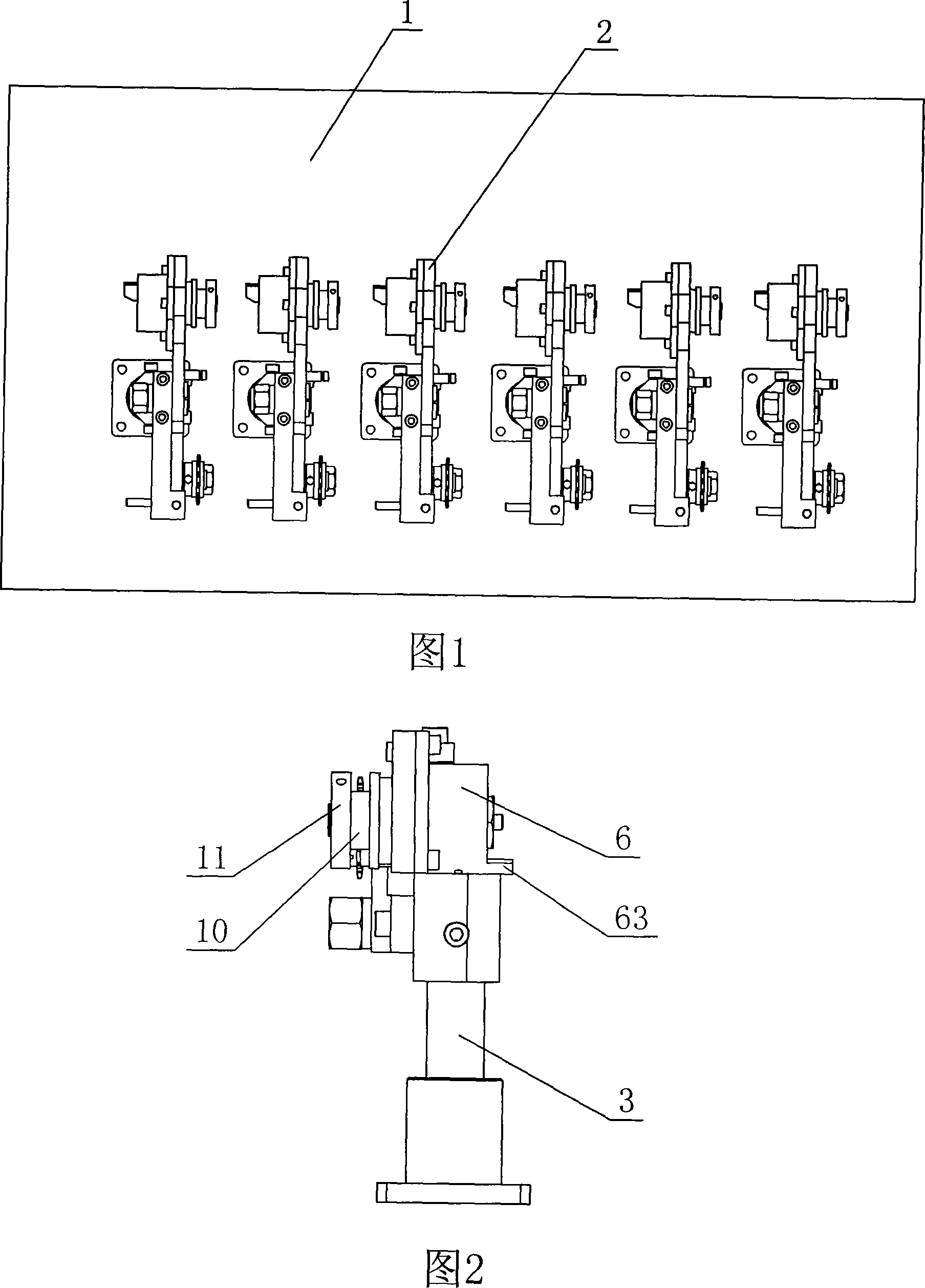

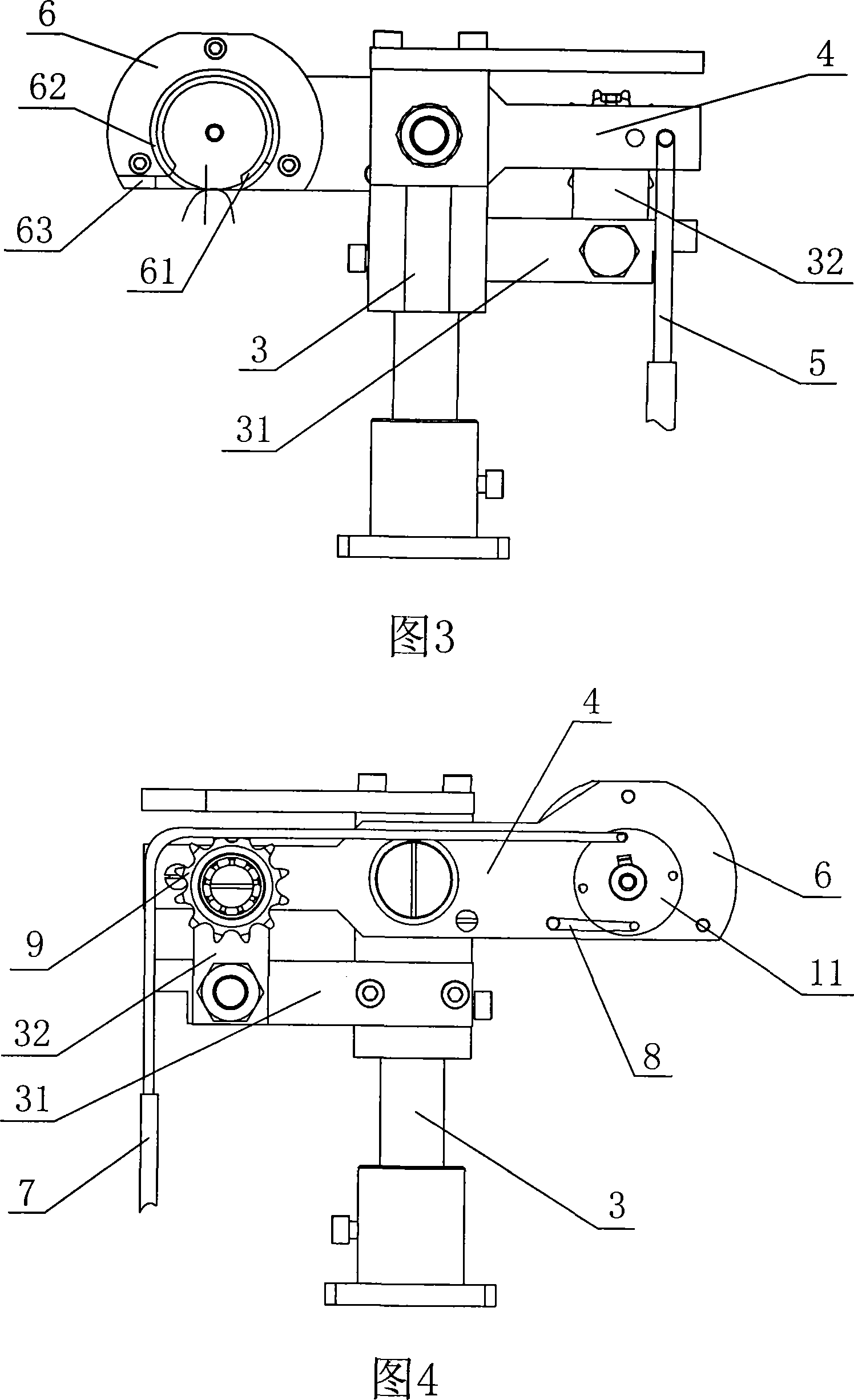

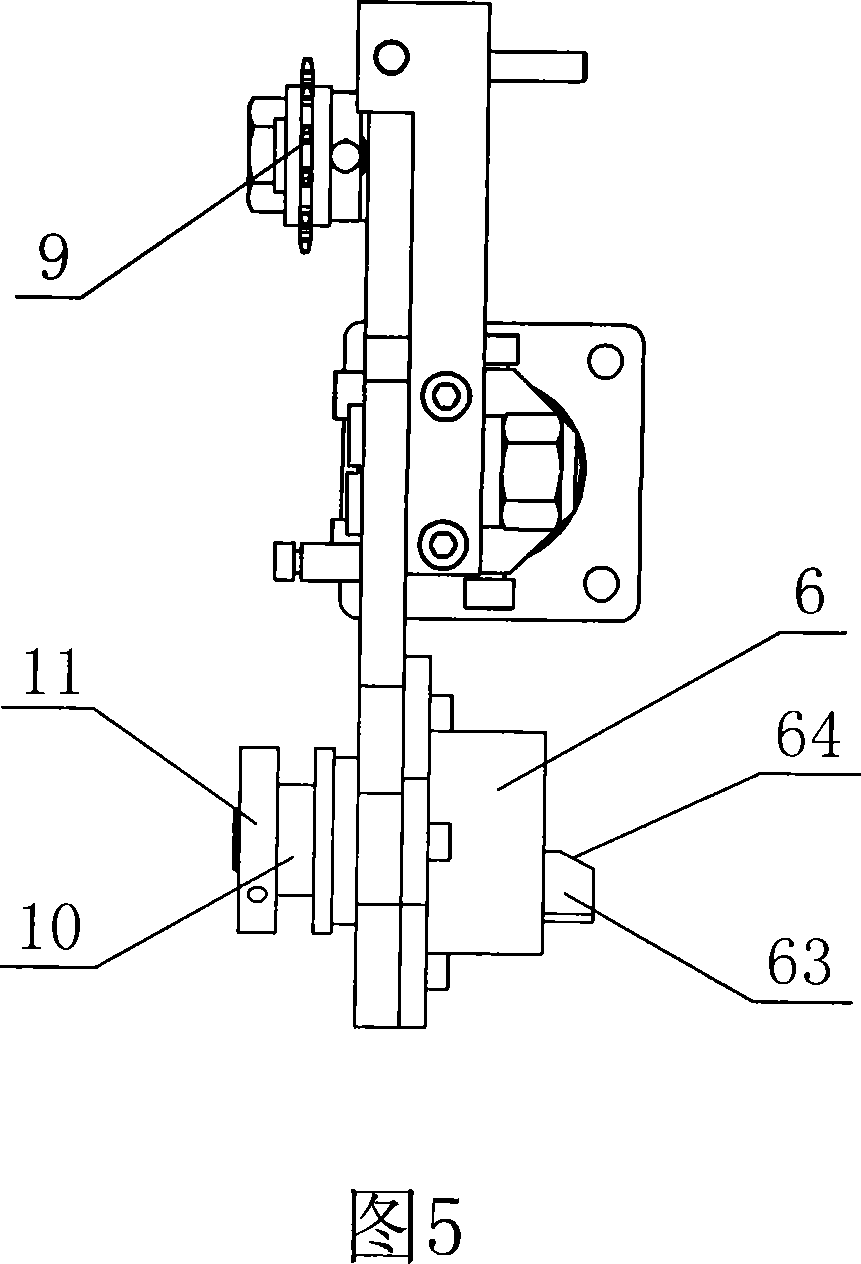

[0018] As shown in the figure, a lead wire cutting device for assembly and production of screw energy-saving lamps includes six cutting mechanisms 2 arranged on a work table 1, and the cutting mechanism 2 includes first vertical supports 3 and The first horizontal support 4, one end of the first horizontal support 4 is connected with the first cylinder pull rod 5, the other end of the first horizontal support 4 is provided with a knife rest 6, and the knife rest 6 includes a coaxially opposite fixed knife rest 61 and a rotating The knife rest 62, the fixed knife rest 61 is fixedly arranged on the first horizontal support 4, the rotating knife rest 62 is fixed on one end of the rotating shaft 10, the rotating shaft 10 passes through and is pivoted on the first horizontal support 4, and the other end of the rotating shaft 10 is fixed A runner 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com