Variable speed drive for a chiller system

一种变速驱动器、冷却器的技术,应用在单个同步机的启动器、控制系统、加热/冷却设备等方向,能够解决设计有效的和低成本的电动机困难、输入电压限制、限制高速感应电动机运转效率等问题,达到改善输入功率品质、成本降低、改善平稳运行的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

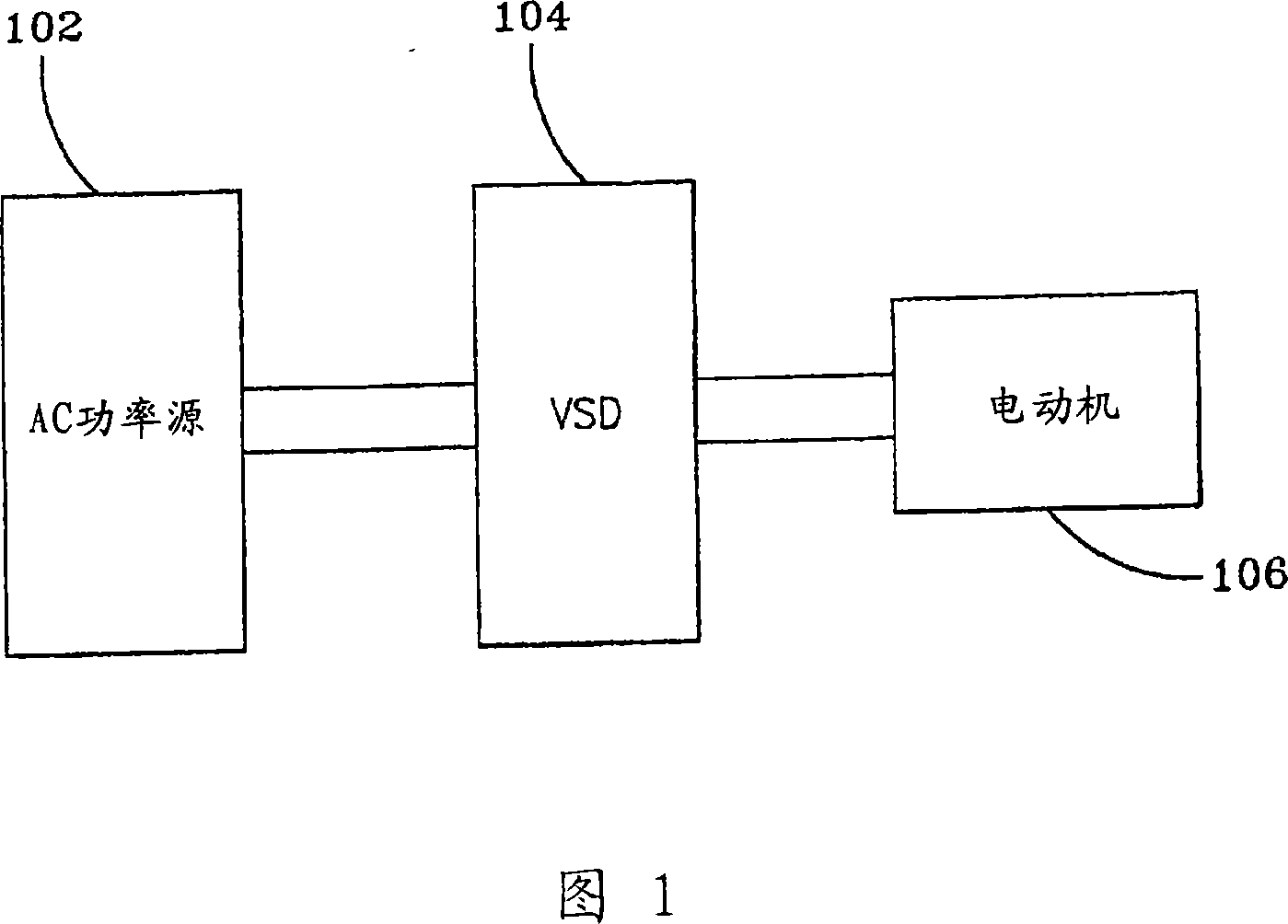

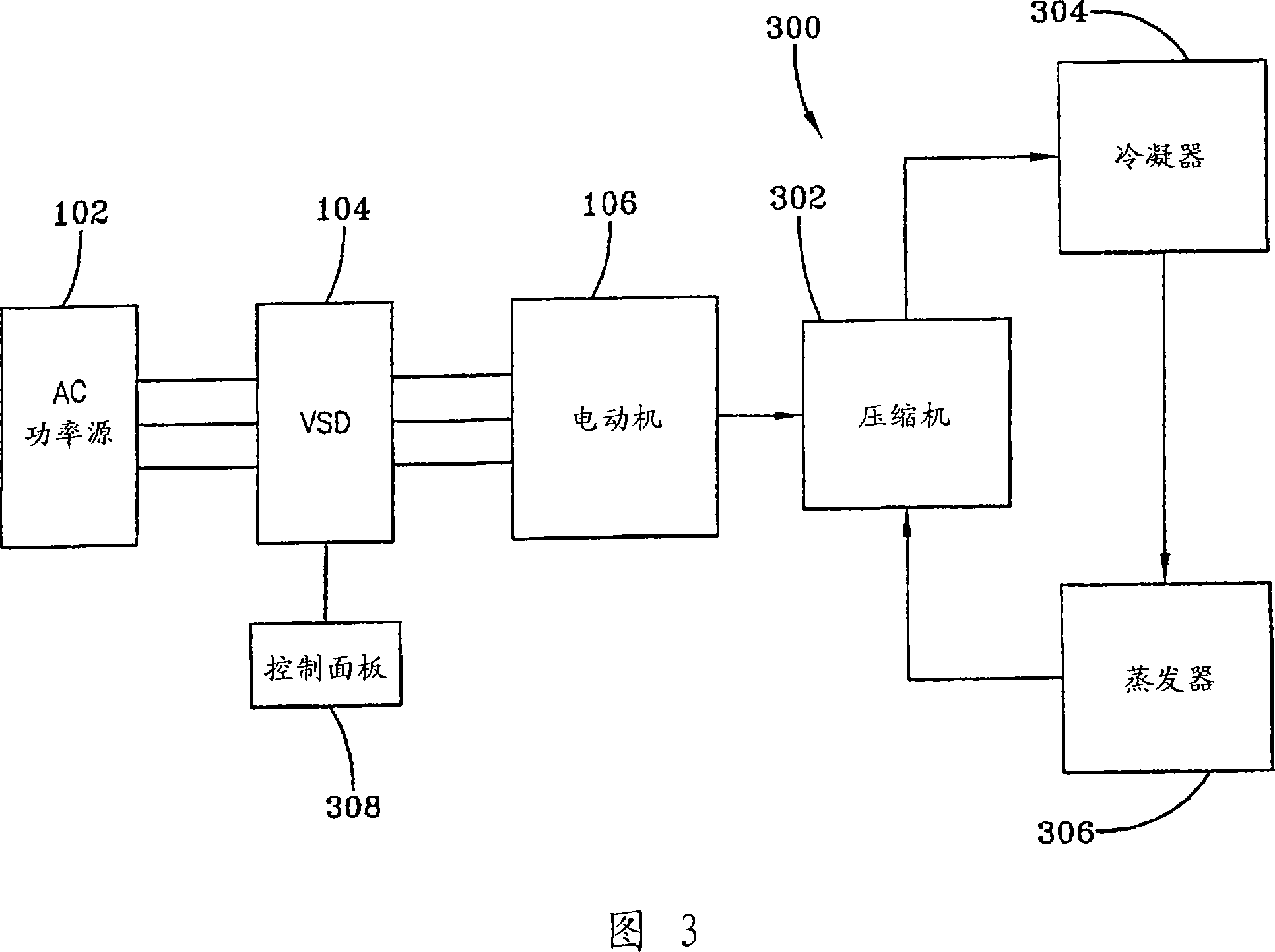

[0021] Figure 1 generally illustrates the system configuration of the present invention. An AC power source 102 supplies AC power to a variable speed drive (VSD) 104 , which in turn supplies AC power to an electric motor 106 . In another embodiment of the invention, VSD 104 is capable of powering more than one electric motor. The electric motor 106 is preferably used to drive a corresponding compressor of a refrigeration or chiller system (see generally FIG. 3 ). AC power source 102 provides single-phase or multi-phase (eg, three-phase) fixed voltage and fixed frequency AC power to VSD 104 from an AC power grid or distribution system provided at the site. The AC power grid can be supplied directly from the power facility or from one or more substations between the power facility and the AC power grid. The AC power source 102 can preferably supply a three-phase AC voltage at a nominal line frequency of 50 Hz or 60 Hz or a nominal line voltage of 200V, 230V, 380V, 460V, or 600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com