Spherical surface photolithography system with area differentiation

A spherical light and differential technology, applied in the field of projection exposure lithography system, can solve the problems of not suitable for quantitative production, difficult imaging exposure, low processing efficiency, etc., to achieve convenient mask replacement, simple selection, and improved reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

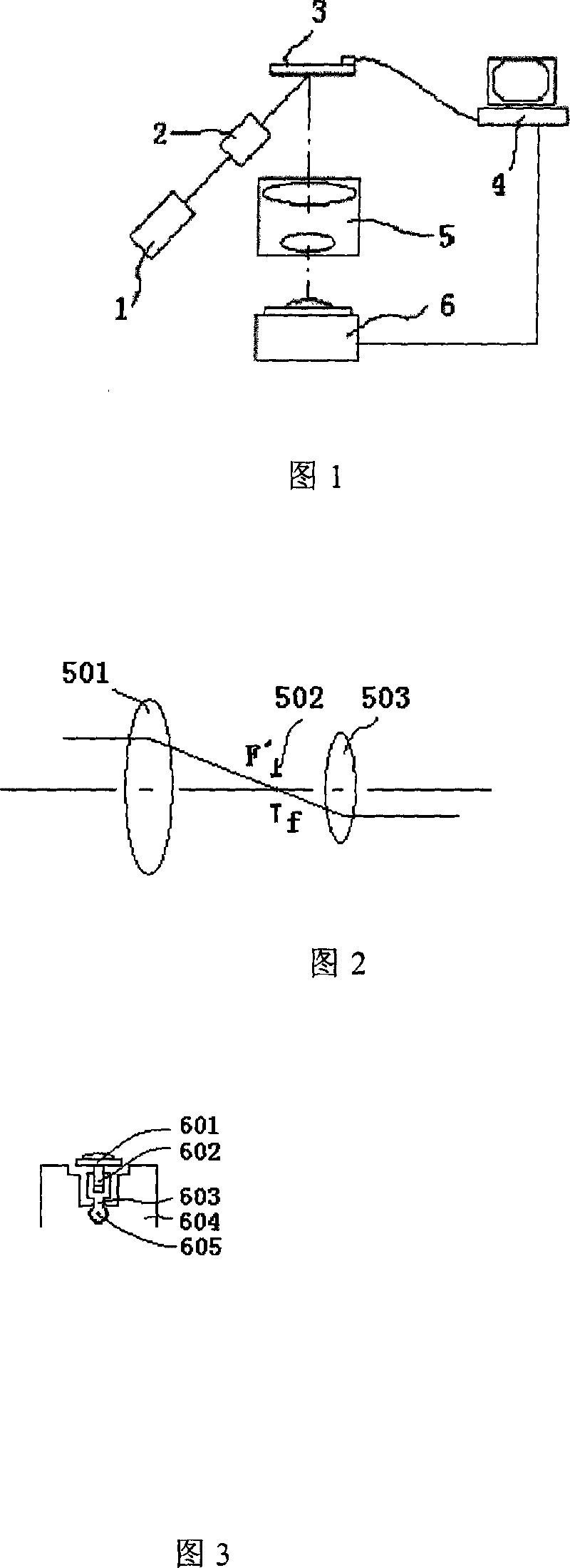

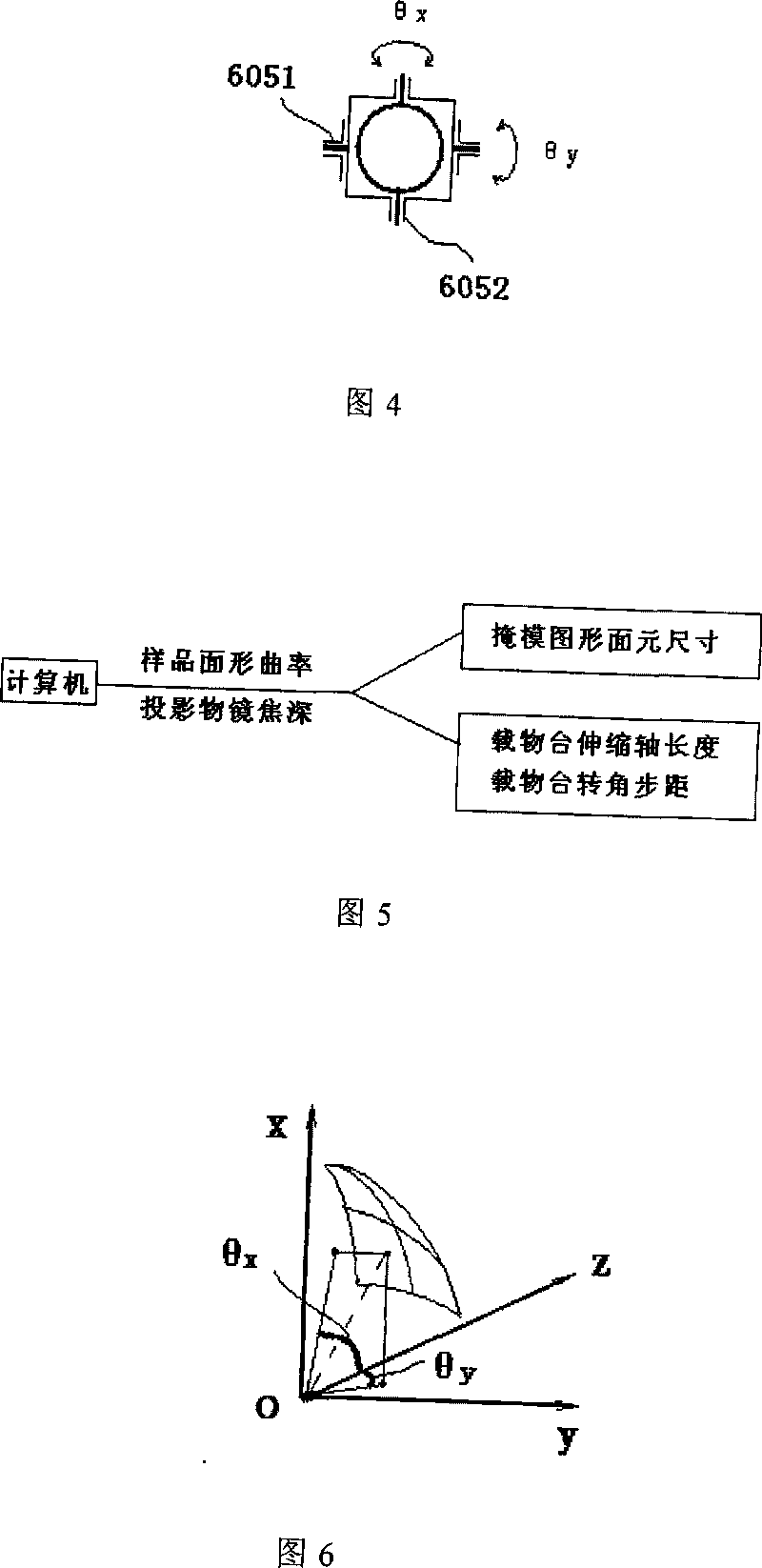

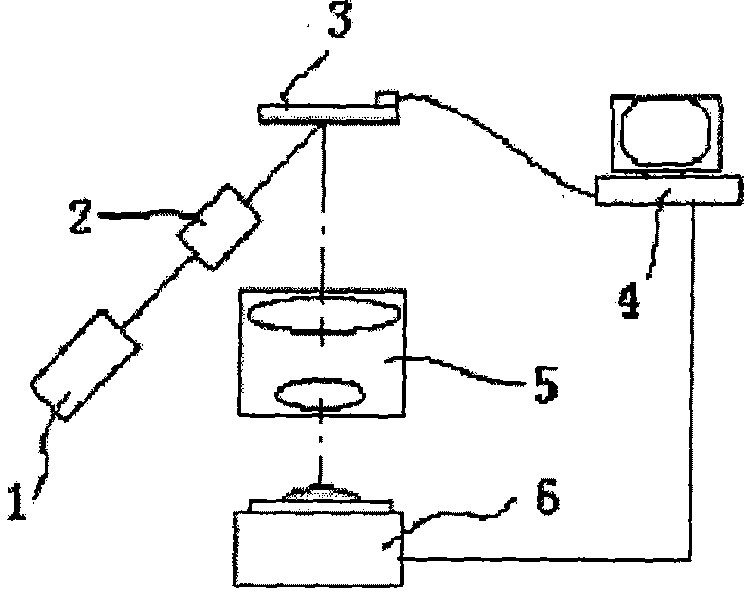

[0017] Such as figure 1 As shown, the embodiment of the present invention is composed of a light source 1 , an illumination system 2 , a mask pattern generator 3 , a computer control system 4 , a projection imaging system 5 , and an object stage 6 . The light source 1 provides the illumination light of the required exposure wavelength for the lithography system. After the illumination light is parallelized and homogenized by the illumination system 2, the mask pattern generator 3 is illuminated, and the mask pattern generator 3 is controlled by the computer control system 4 to provide a mask. At the same time, the computer control system 4 divides the exposure field according to the curvature of the sample and the focal depth of the projection imaging system 5, so that the imaging in the exposure unit is not out of focus, and the projection imaging system 5 provides the mask pattern image provided by the mask pattern generator 3 on the sample Above, the stage 6 is used to inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com