Stalk cutting test device and method

A test device and cutting device technology, which is applied in the direction of measuring device, cutting equipment, machine/structural component testing, etc., can solve the problems of difficult accurate measurement of header loss rate, increased power consumption, and difficulties in real-time signal acquisition and processing, etc. The operation method is stable and reliable, and the device is simple and reasonable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

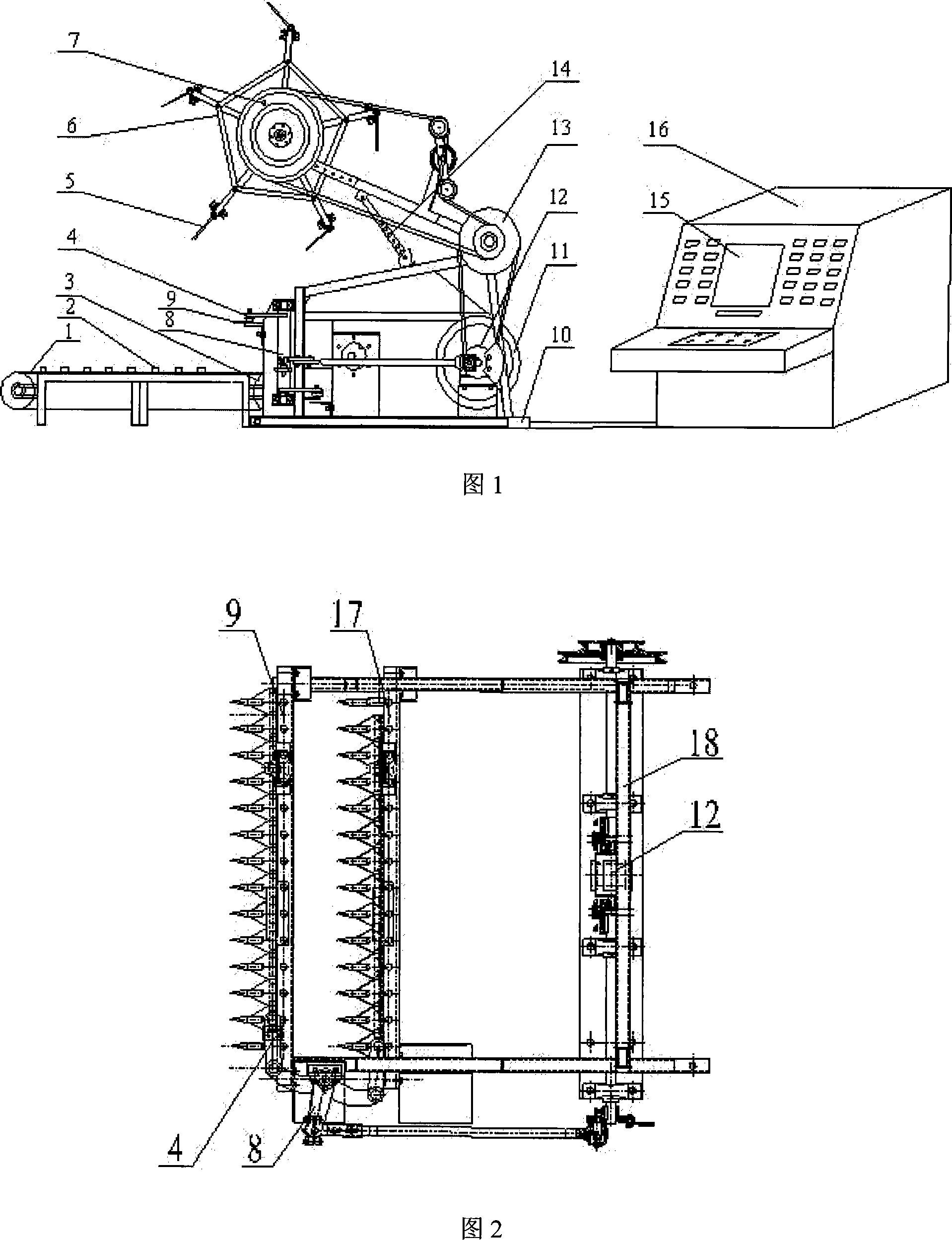

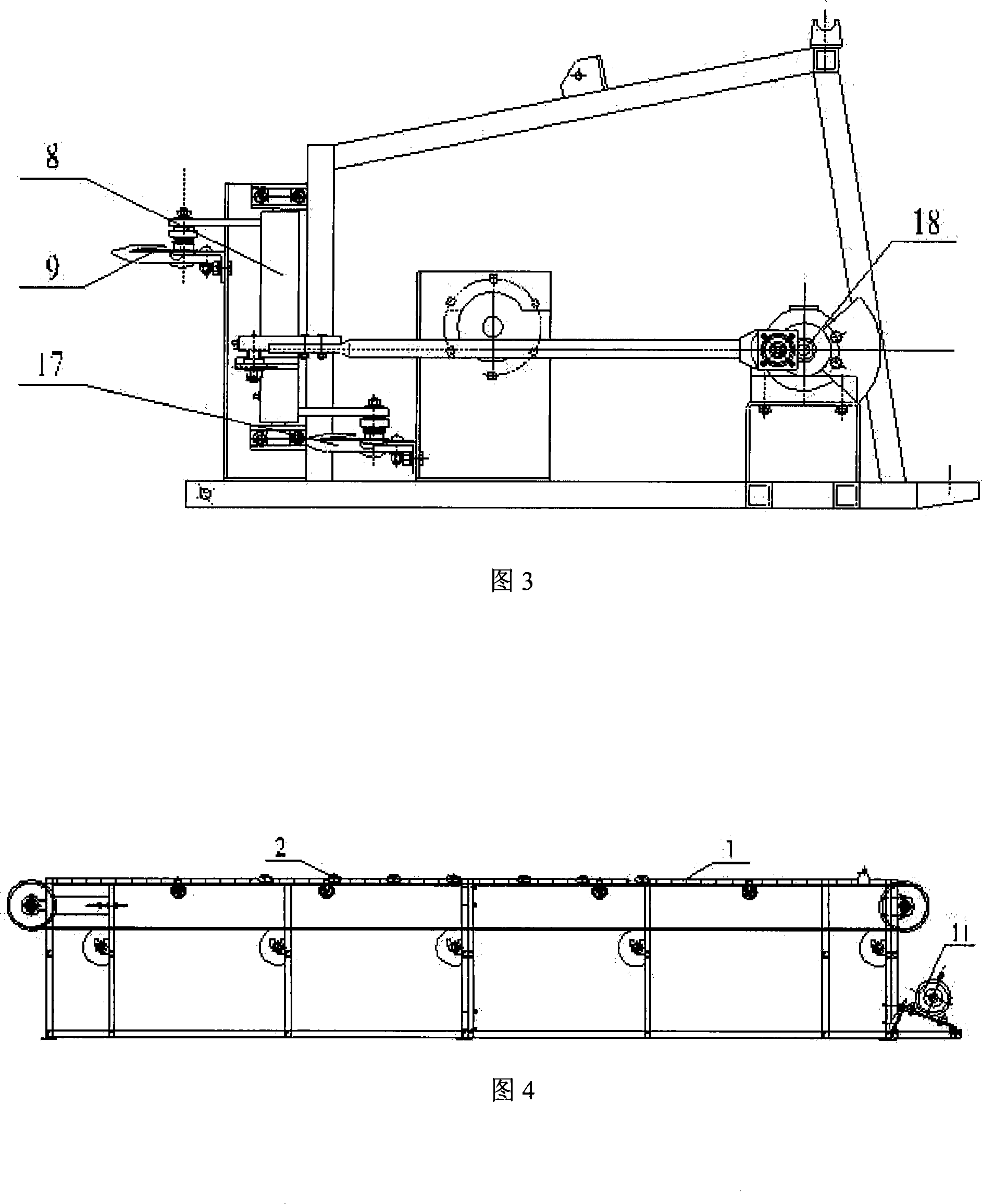

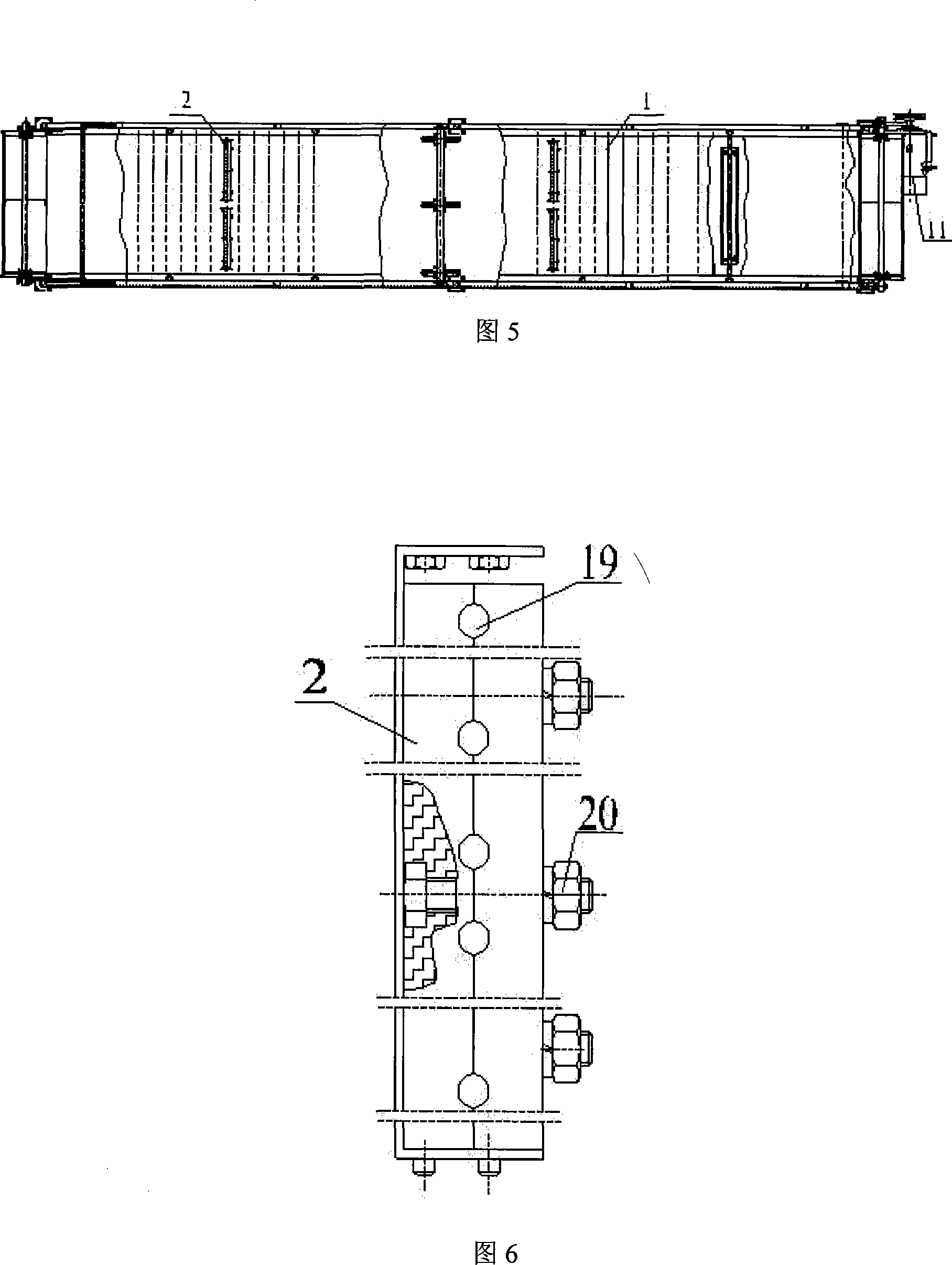

[0019] As shown in Figure 1, it is a structural diagram of the stalk cutting test device, which mainly includes a conveying device, a cutting device, a reeling device and a monitoring and control system. The conveying device includes a driving motor 11 connected to an adjustable-speed conveying belt 1 , and a rotational speed sensor 3 is installed on the shaft end of the roller of the conveying belt 1 . As shown in Figures 4, 5 and 6, the stalk holder 2 fixed on the conveyor belt 1 and capable of clamping the stalks of crops is mainly composed of stalk clamping holes 19 and clamping bolts 20, and the stalks of crops are pressed Put a certain row spacing and plant spacing into the stalk clamping hole 19, and the stalk clamper 2 is fixed on the conveyor belt 1 through the clamping bolt 20. During the test, the stalk clamp can be adjusted according to the plant spacing and row spacing of different crops. The holding device 2 can be used to meet the required plant spacing and row ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com