Cooling fan control device and method

A cooling fan and control device technology, which is applied in the direction of coolant flow control, power plant cooling combination arrangement, pump control, etc., can solve the problems of reduced work efficiency, increased energy consumption, poor cooling effect, etc., and achieve improved operation Efficiency, work efficiency improvement, strong robustness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

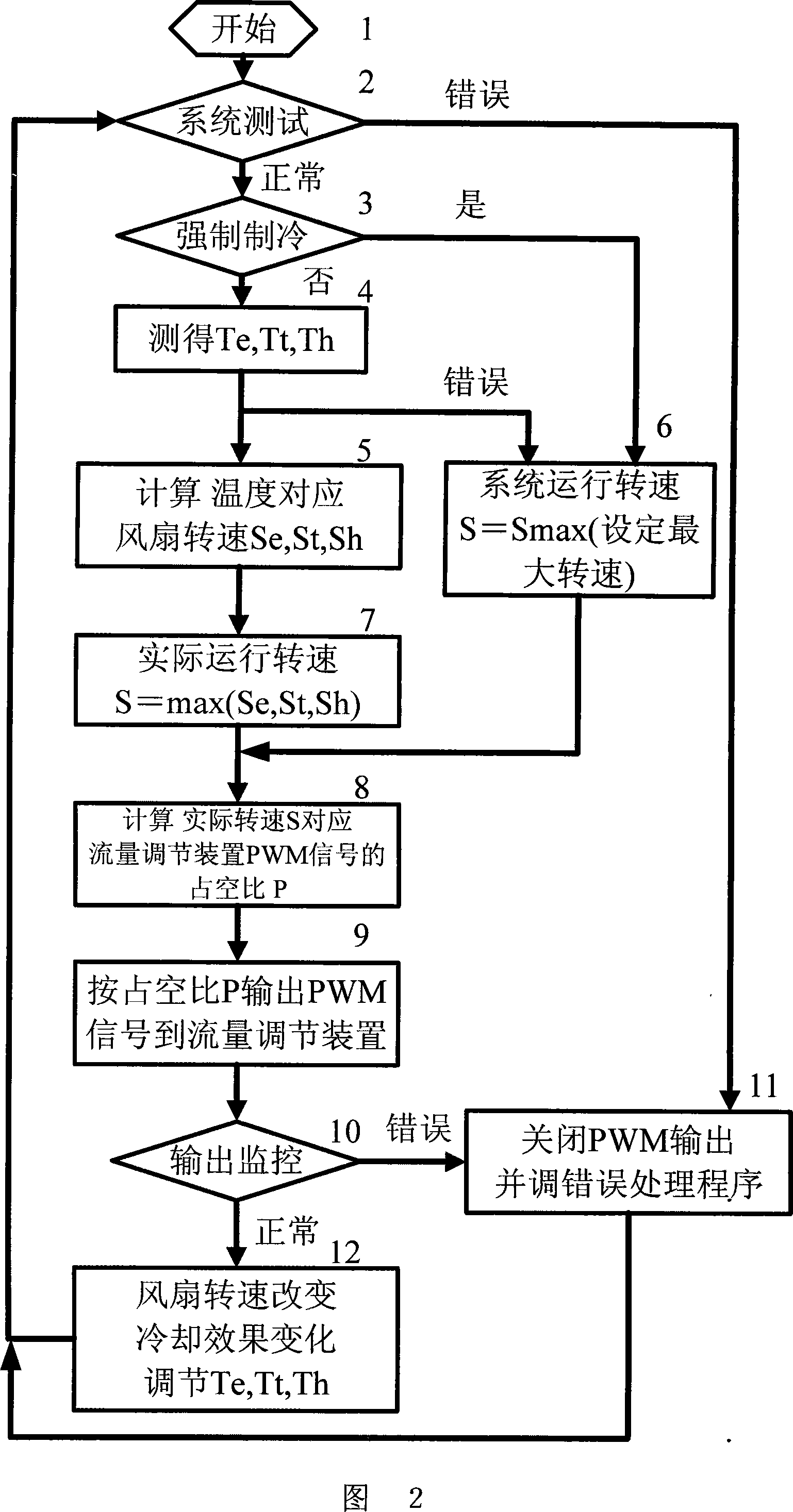

[0045] The bulldozer adopts a cooling fan control device of the present invention. Through the above-mentioned corresponding control method, by changing the speed of the cooling fan, the air volume through the cooling system is changed, and the cooling effect is changed, so that each cooling working medium maintains Within the normal range.

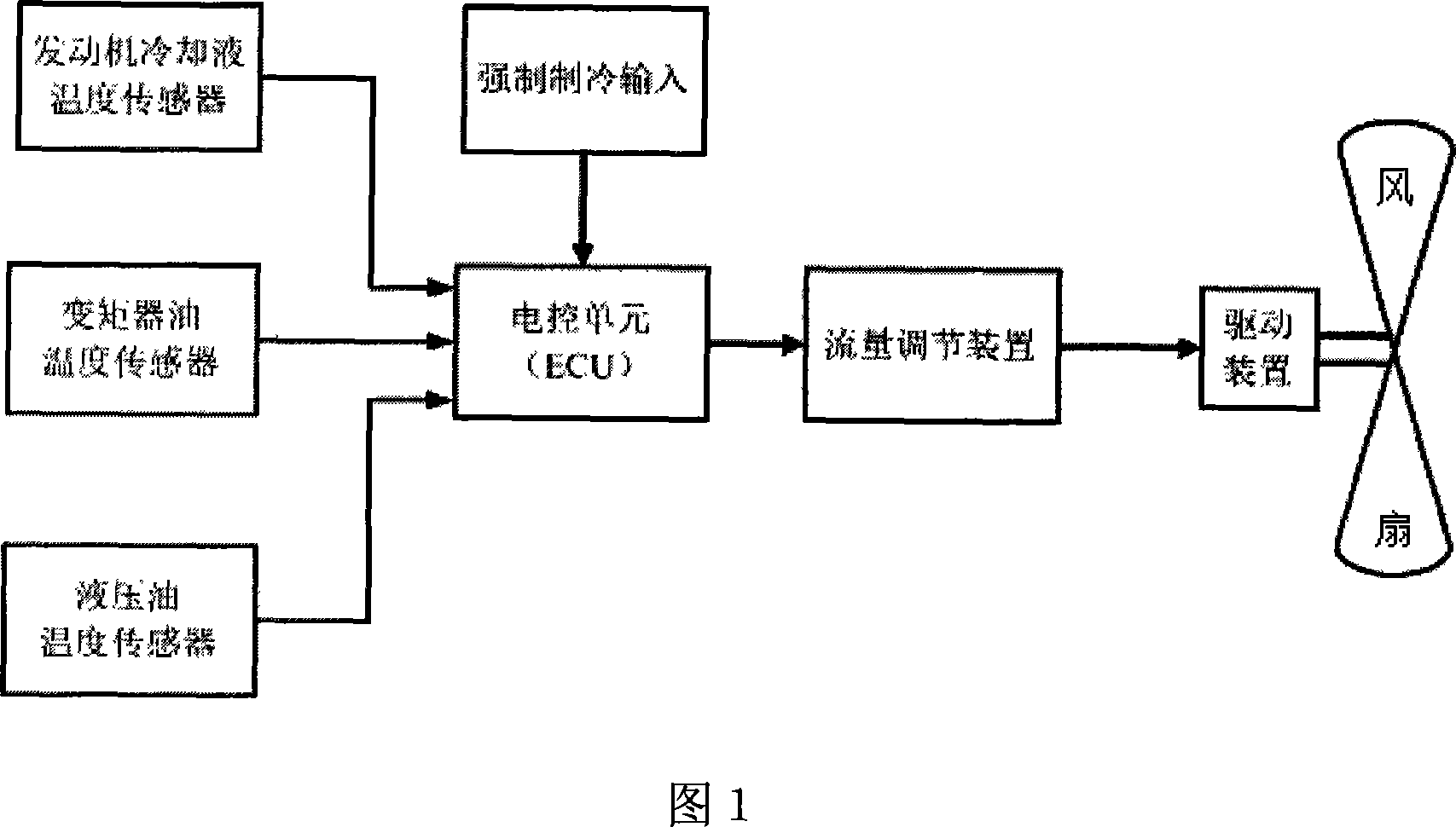

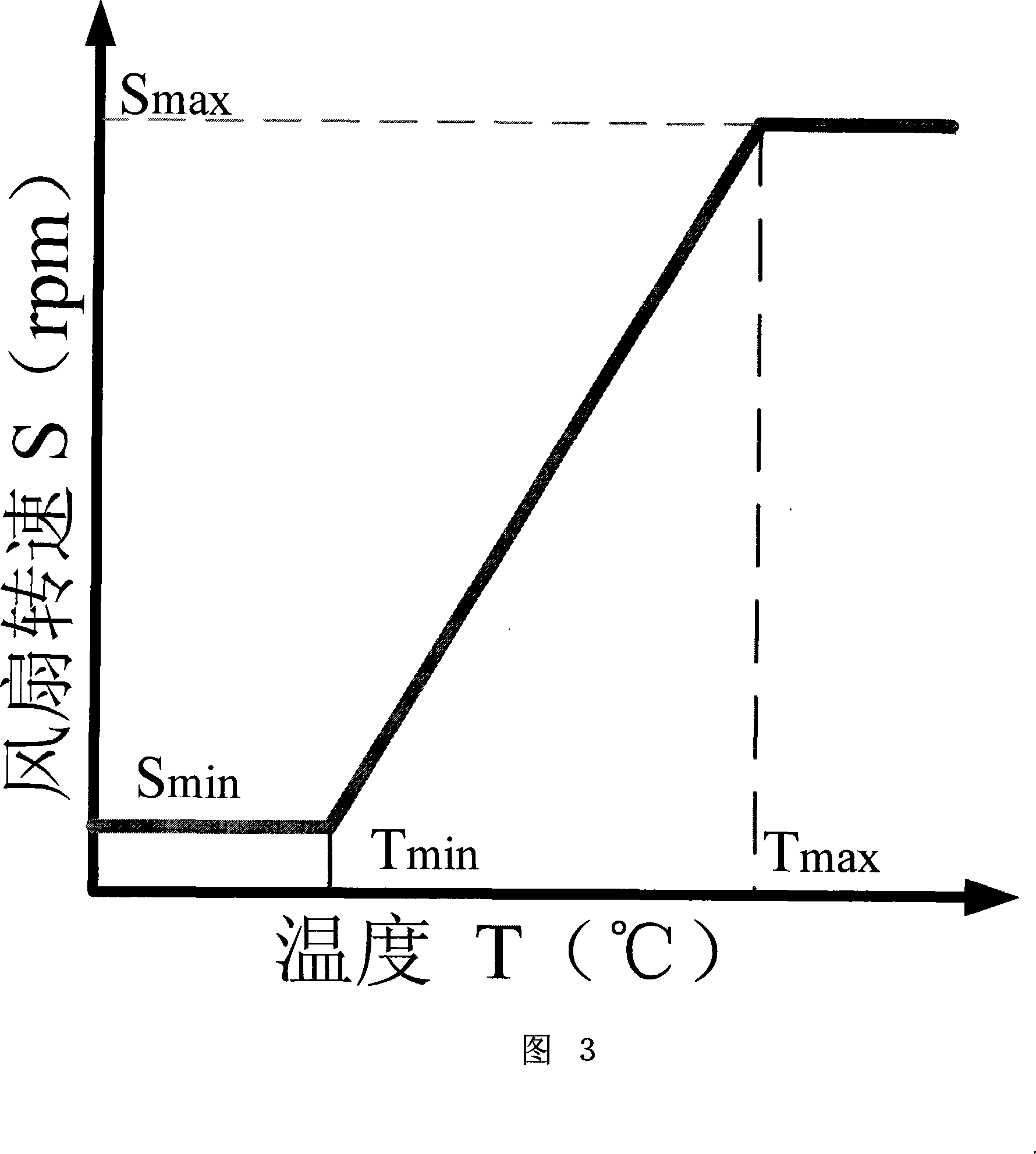

[0046] In the cooling fan control device, the electronic control unit receives the engine cooler temperature signal, the torque converter oil temperature signal and the hydraulic oil temperature signal collected by the temperature sensor, and according to the corresponding relationship between the temperature and speed set by the system, according to the engine cooler temperature Find the corresponding speed Se according to the relationship between the fan speed and the torque converter oil temperature and the fan speed; Find the corresponding speed Sh according to the relationship between the hydraulic oil temperature and the fan speed; and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com