Automatic control system and method of hydraulic multi-cylinder cone crusher

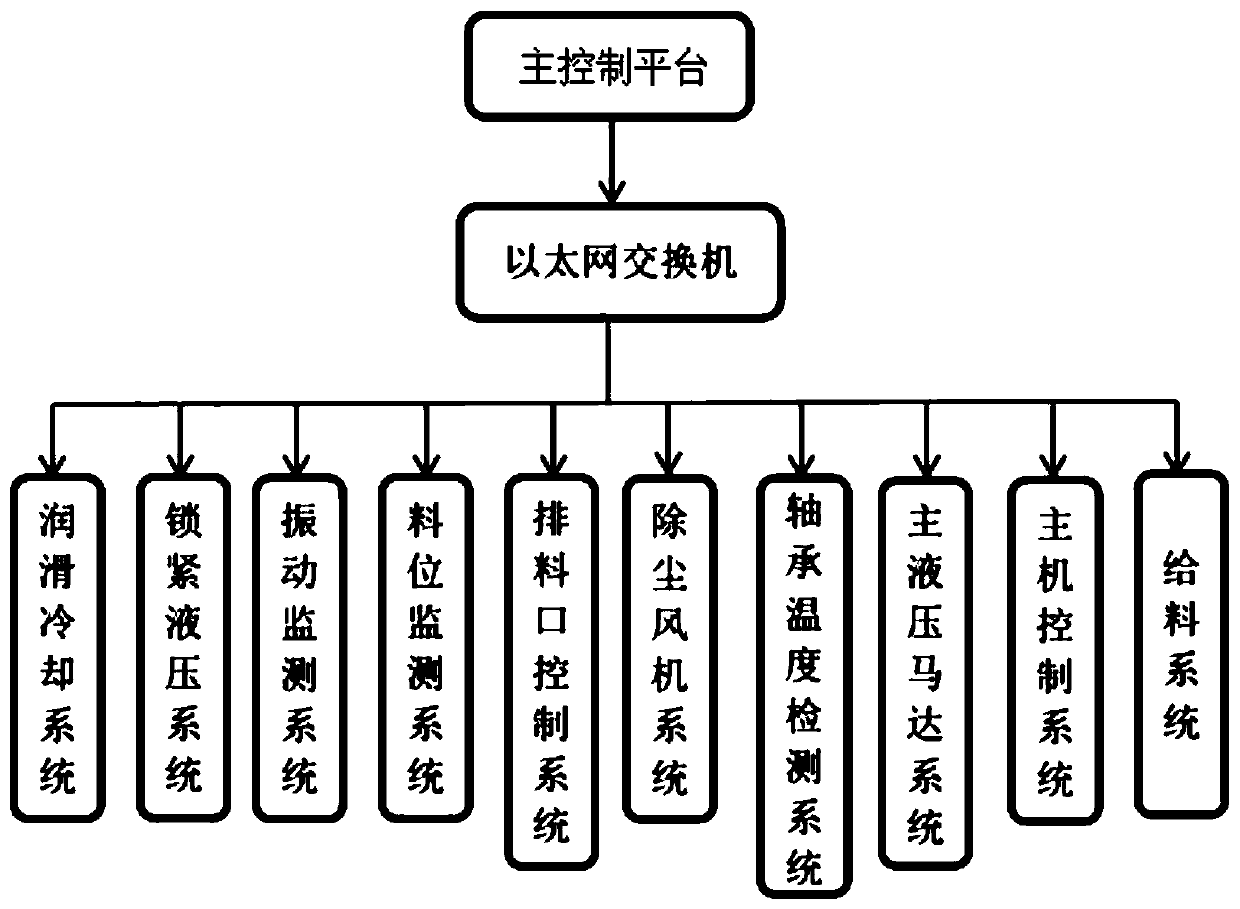

An automatic control system and cone crusher technology, applied in grain processing and other directions, can solve problems such as belts and couplings being easily damaged, power loss, etc., to prevent overload operation, improve service life, and facilitate information collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is further explained in detail below in conjunction with the accompanying drawings.

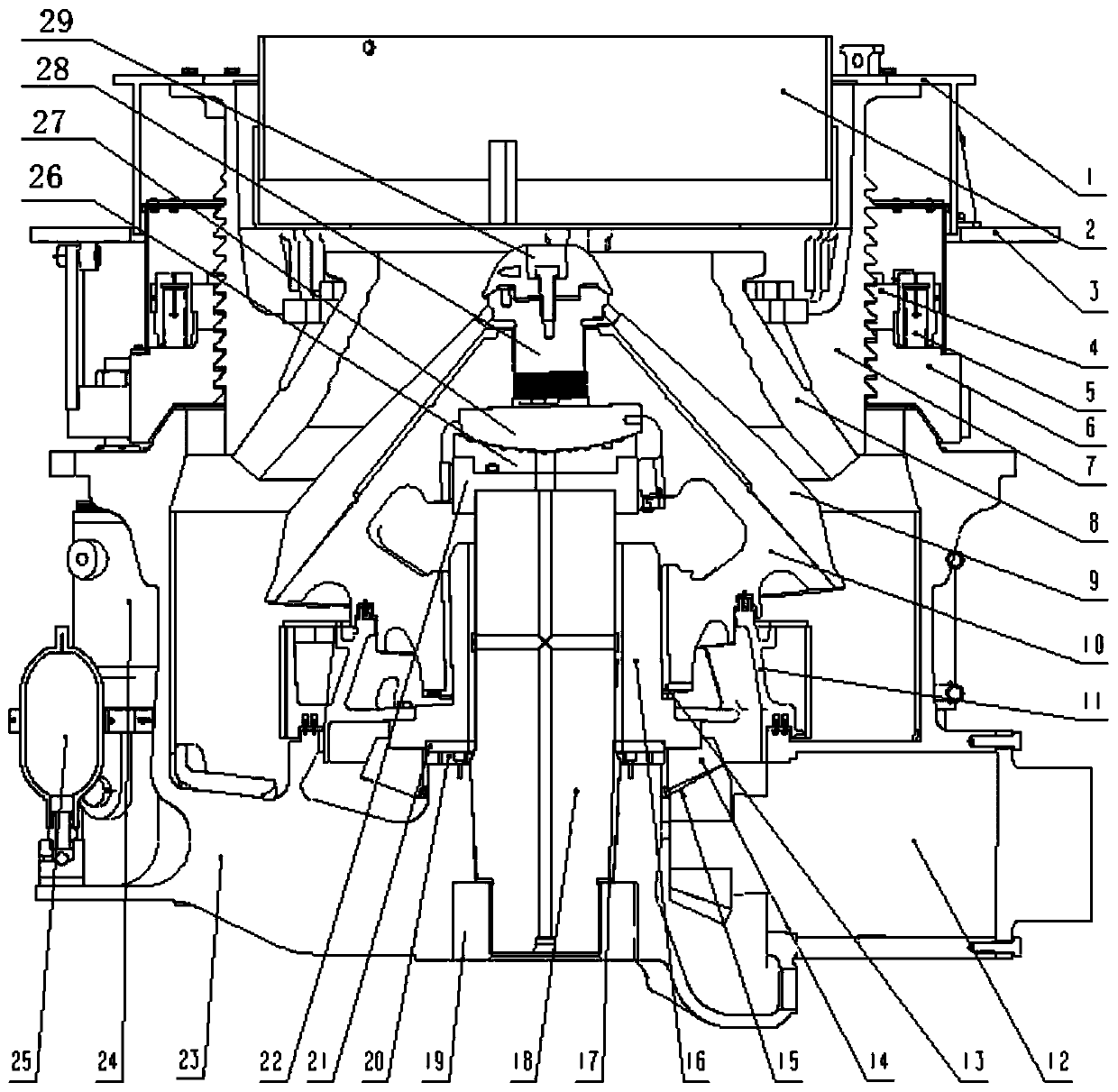

[0050] The main structure of the hydraulic multi-cylinder hydraulic cone crusher is as follows: figure 1 with figure 2As shown, it mainly includes frame 23, fixed cone assembly, movable cone assembly, eccentric assembly, main shaft 18, main drive hydraulic motor 12, movable cone assembly and eccentric assembly are assembled on the main shaft 18, main drive hydraulic motor 12 is installed on the frame, the main drive hydraulic motor 12 is connected to the eccentric assembly through gears, the eccentric assembly is connected to the moving cone assembly, the fixed cone assembly is connected to the frame 23 through the release cylinder 24, and the main shaft 18 is connected to the machine frame through the hydraulic nut 19. Frame 23 is assembled.

[0051] The counterbore at the bottom of the frame 23 is used to install the hydraulic nut 19. The hydraulic nut 19 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com