Fixation cell (or enzyme) internal circulation fluidized bed reactor and application thereof in organic phase biological catalysis

A technology of fluidized bed reactor and immobilized cells, which is applied in the direction of supporting/immobilizing microorganisms, special-purpose bioreactors/fermenters, biochemical cleaning devices, etc., to achieve high oxygen dissolution efficiency and low shear force , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

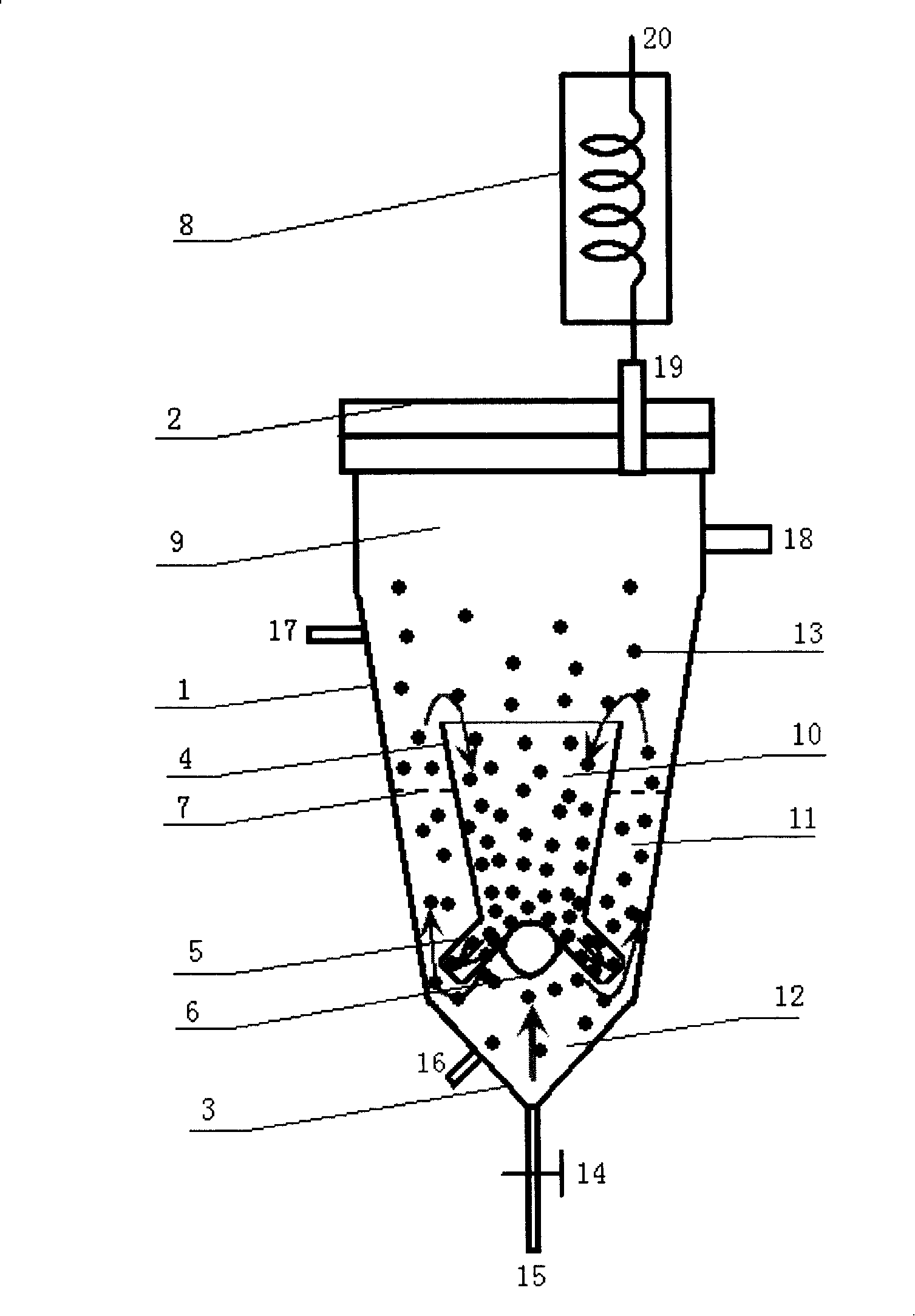

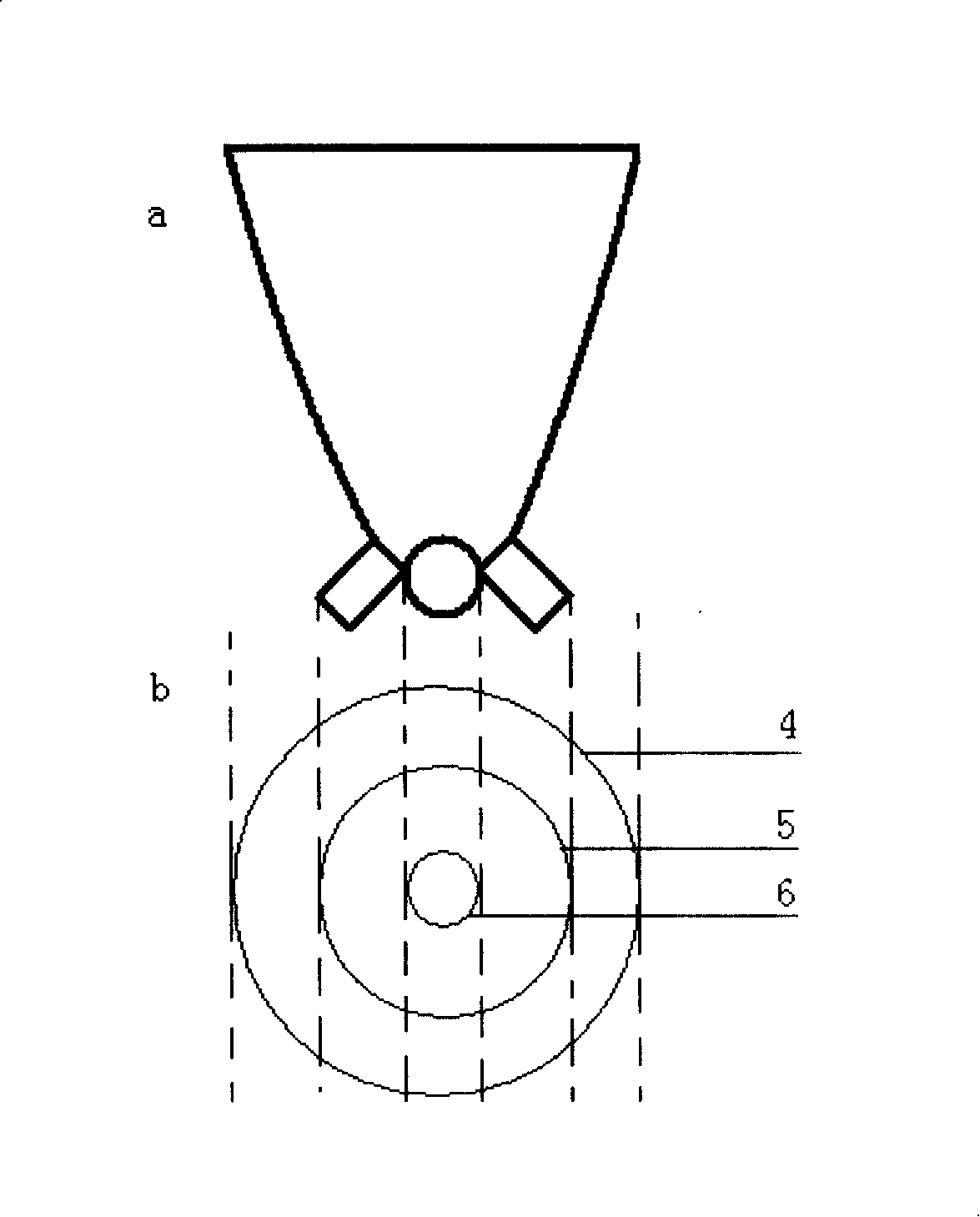

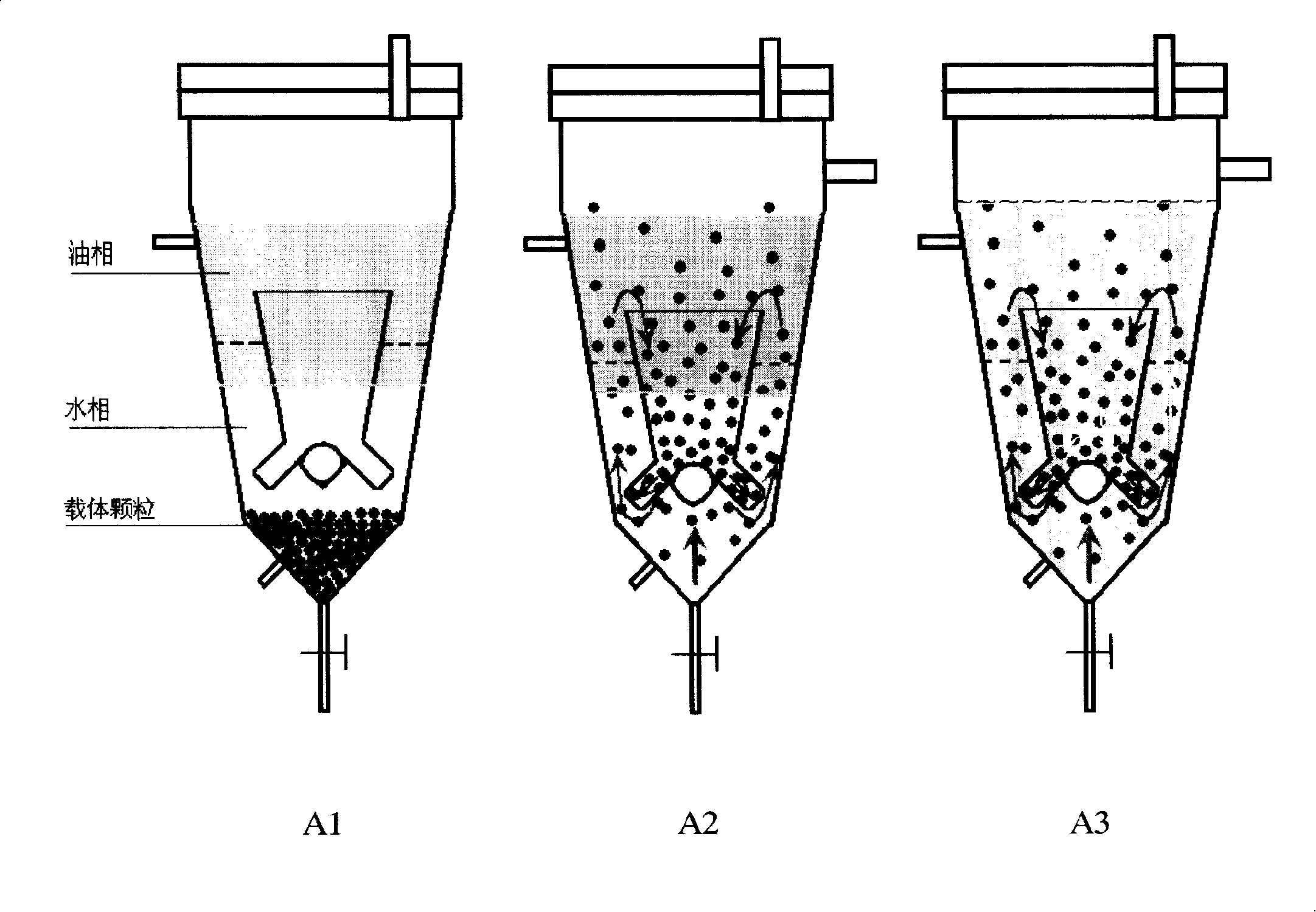

[0041] See Figure 1~3 According to the connection relationship of the aforementioned reactors, a circulating fluidized bed reactor in immobilized cells (or enzymes) that can be used as an organic phase biocatalytic reaction is produced.

[0042] The circulating fluidized bed reactor for immobilized cells (or enzymes) provided in this example has a height of 350 mm, a volume of 700 mL, and an effective volume of 500 mL. The lower part of the reactor shell is equipped with an external heat exchange jacket for cold and hot water to control the reaction temperature.

Embodiment 2

[0044] Batch immobilized cell biocatalysis for desulfurization reaction.

[0045] Using the circulating fluidized bed reactor in the immobilized cells (or enzymes) made in Example 1, the immobilized biocatalyst was used to remove sulfur in the simulated oil phase. The steps are as follows:

[0046] (1) Cultivation of biological desulfurization bacteria

[0047] Take 0.5 mL of glycerol-preserved Pseudomonas delafildii R-8 strain (Pseudomonas delafildii R-8, CGMCC NO.0570), add to several Erlenmeyer flasks containing 150 mL of culture medium, at 30°C, 170r Cultivate for 2 to 3 days under the condition of 1 / min; centrifuge to obtain R-8 cells, wash 2 to 3 times with normal saline, and suspend the obtained Pseudomonas delbruecki R-8 cells in normal saline, store in a refrigerator at 4°C placed in.

[0048] The composition of the medium is 2.44 g KH per liter of water 2 PO 4 , 14.03 g Na 2 HPO 4 12H 2 O, 0.4g MgCl 2 ·6H 2 O, 0.001g CaCl 2 2H 2 O, 0.001g FeCl 3 ·6H 2 O...

Embodiment 3

[0055] Continuous biocatalytic removal of sulfur from diesel with immobilized cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com