Method for preparing foaming agent used for oil gas field drilling and extracting

A foaming agent, a technology for oil and gas fields, applied in drilling compositions, chemical instruments and methods, organic chemistry, etc., can solve the problems of gas being carried out of the ground, interfere with the smooth progress of drilling, etc., and achieve high conversion rate of tertiary amine, reaction The effect of shortening time and improving surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

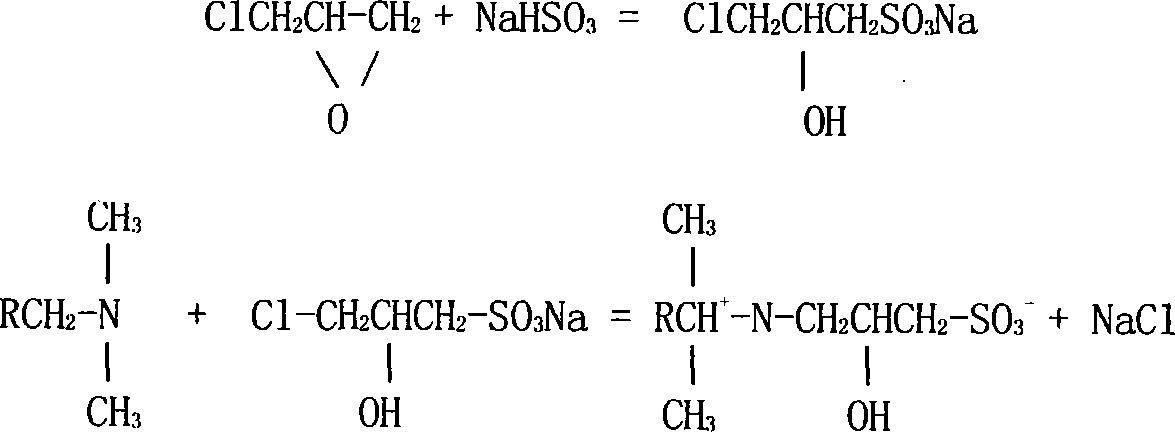

Method used

Image

Examples

example 1

[0017] Example 1. Add 415 grams of 27.5% sodium bisulfite solution in a 1-liter reactor, add 10% NaOH solution 1ml, put the lid on the reactor, heat to 65°C under stirring, then add epichlorohydrin 100 gram, was reacted at 65-75°C for 2.5 hours, and the reactant was aged at 70°C for 1 hour, and 190ml of water was added to obtain 706 grams of 30% 3-chloro-2-hydroxypropyl sodium sulfonate solution.

[0018] In a 1000ml three-necked flask, add 330 grams of 30% 3-chloro-2-hydroxypropyl sodium sulfonate solution, 120 ml of deionized water, and then add 50 grams of anionic surfactant (IV), and heat to 75 ° C. Stir at high temperature for 30 minutes, add 100 grams of dodecyldimethylamine, use phenolphthalein as indicator, add 10% NaOH solution dropwise, control the pH value of the reaction system at 7.5-8.5, and continue to react at 75-95°C After 8 hours, a yellowish viscous liquid was obtained. The free amine value was measured, and the conversion rate of the tertiary amine was ≥99....

example 2

[0019] Example 2. In a 1000ml three-neck flask, add 100 grams of C 12-14 Dimethyl tertiary amine, 190ml deionized water, 30 grams of anionic surfactant (IV), then add 300 grams of 30% 3-chloro-2-hydroxypropyl sodium sulfonate solution prepared in Example 1, and heat to 85°C , and stirred for 1 hour. Use phenolphthalein as an indicator, add 15% NaOH solution dropwise, control the pH value of the reaction system at 7.5-8.5, keep it at 75-95°C and continue the reaction for 8 hours to obtain a relatively viscous liquid, and measure its residual tertiary amine ≤ 0.5%

example 3

[0020] Example 3. Foam performance test. Here, the Waring Blender stirring method is used to test the foam performance of the blowing agent under different conditions. The U.S. petroleum industry often adopts this method, and my country's petroleum industry usually also adopts this method. The instrument used is a Waring-Blender mixer. During the test, add 100ml of test solution into a graduated mixing cup, stir at a high speed (≥5000rpm) for 60s, turn off the switch, and immediately record the foam volume (V), which is used to represent the foaming agent The foaming ability, the larger the V, the stronger the foaming ability. Then record the time (t) required to separate out 50ml of liquid from the foam, called the (drainage) half-life of the foam, reflecting the stability of the foam, the longer t, the more stable the foam. Foaming ability and foam stability are the most important performances of blowing agents, therefore, the values of V and t can better represent the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com