Method for producing ursodeoxycholic acid by using swine bladder as raw material

A technology of ursodeoxycholic acid and chenodeoxycholic acid, which is applied in the field of preparation of ursodeoxycholic acid, and can solve the problem of unnoticed removal of impurities such as fat and protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

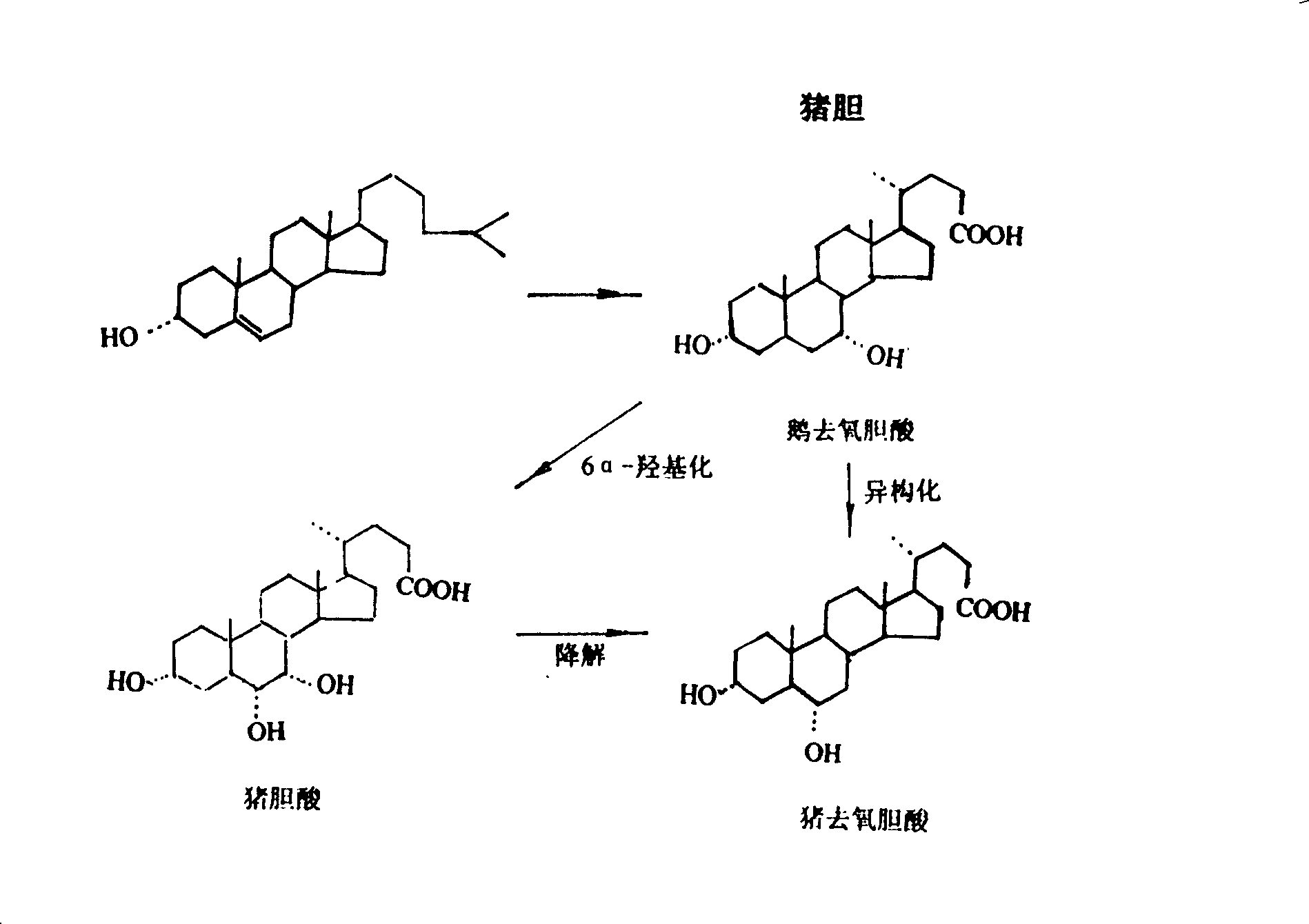

Method used

Image

Examples

Embodiment 1

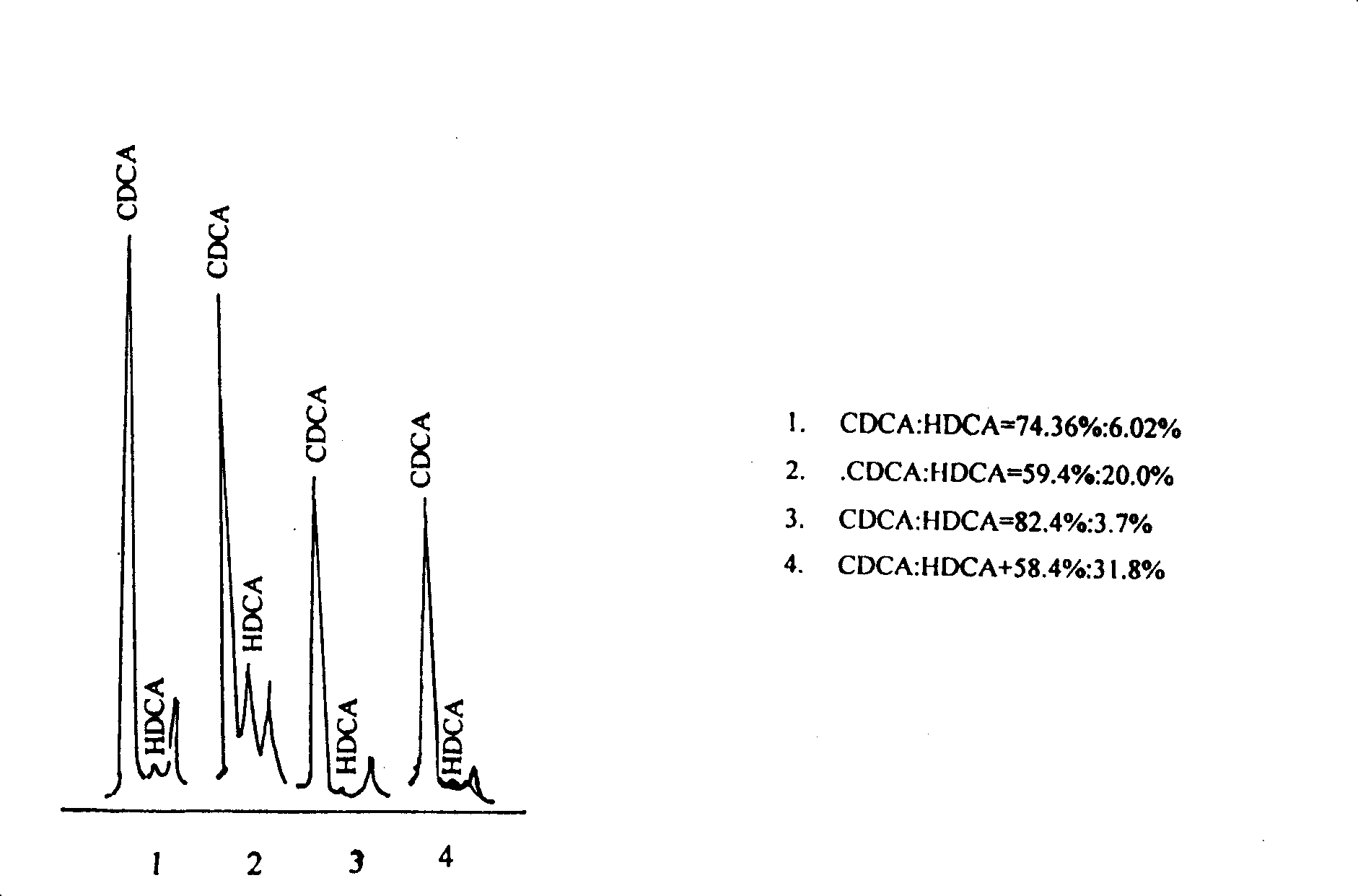

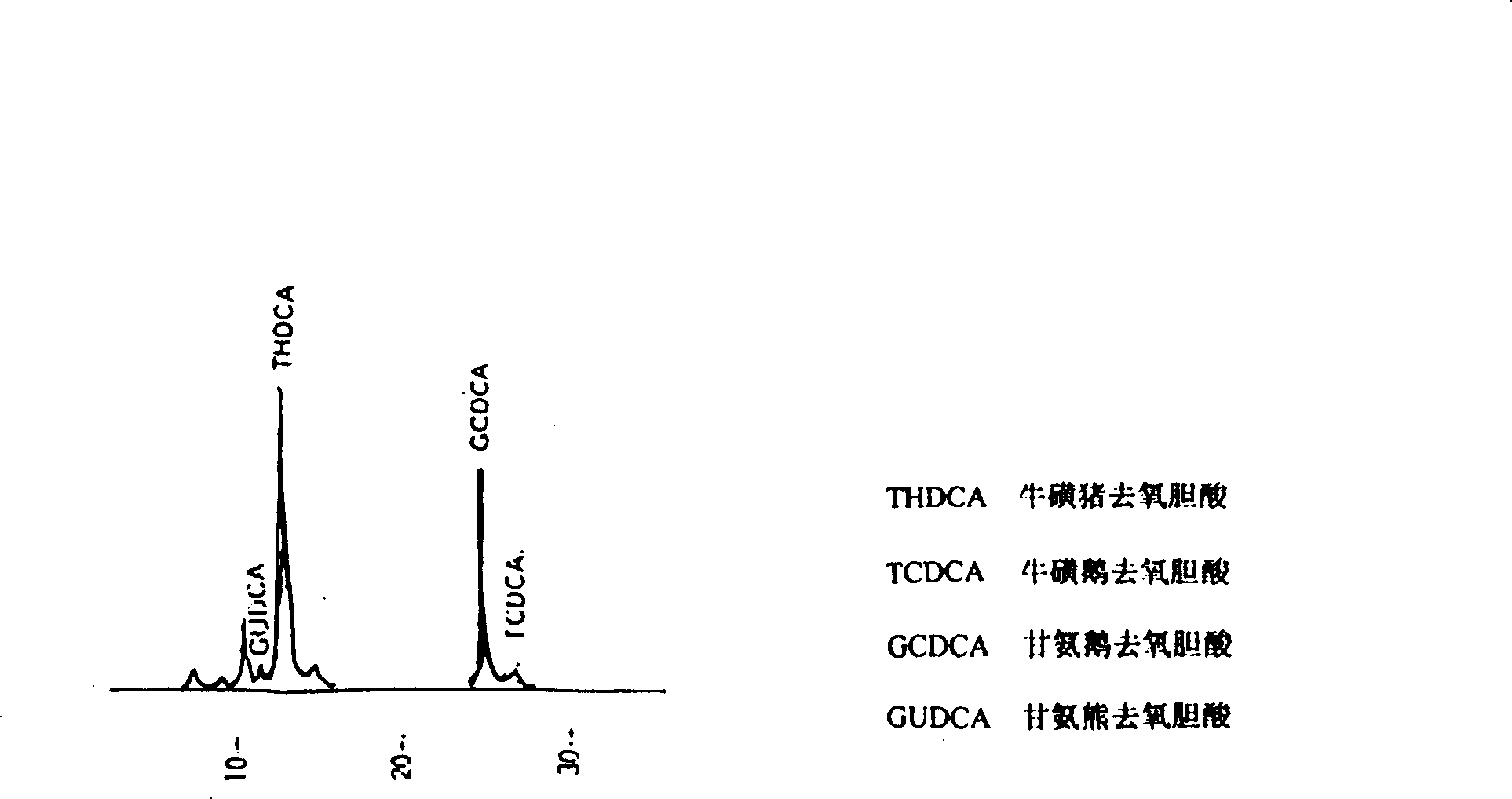

[0031] Example 1: Separation of Precipitated Porcine Conjugated Bile Acid and Chenodeoxycholic Acid

[0032] Take fresh pig bile, add 3-4% saturated lime water, boil, generate bilirubin calcium salt precipitate, filter it out, and reserve it for the production of bilirubin for later use. Acidify the filtered bile with dilute hydrochloric acid to PH2-3, precipitate porcine conjugated bile acid, filter, boil and wash the filtered porcine conjugated bile acid with water twice, add about 8-10 times of 10% NaOH aqueous solution, heat and reflux for hydrolysis 20-24 hours, acidify with dilute hydrochloric acid or dilute sulfuric acid to PH8-9, heat to boil, after cooling, add 3-4% hydrogen peroxide to decolorize, then acidify with dilute hydrochloric acid to PH2-3, separate out free porcine bile acid, wash to medium sex. Add 15-20% NaOH aqueous solution and stir. At this time, hyodeoxycholic acid is difficult to dissolve and precipitate, and hyodeoxycholic acid and chenodeoxycholic...

Embodiment 2

[0034] Embodiment 2: the preparation of ursodeoxycholic acid

[0035] Take chenodeoxycholic acid 20g, dissolve in 1000ml glacial acetic acid, add sodium acetate 150-200g. After stirring to dissolve it, then add 15-20g of potassium chromate (in 100ml of water), let it stand at room temperature overnight, add 180-200ml of water, precipitate crystals, filter, wash with water, and dry to obtain a white powder, which is 3a-hydroxy- 7-ketocholanic acid (m.p.194-196°C), yield 84-85%.

[0036] Take 40g of 3a-hydroxy-7-ketocholanic acid and put it in a 3000ml three-neck bottle, add 1L of n-butanol and stir to dissolve, when the temperature rises to about 115-120°C, start adding 75-80g of sodium metal in portions. After reacting to the complete disappearance of the sodium metal on the liquid surface, white flocs are gradually separated out, continue to react for half an hour, add 1200ml of water and heat up under stirring to make it dissolve until transparent. Then the organic solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com