Rolling cutter grinder

A pulverizer and hob-type technology, which is applied in the fields of tobacco, grain processing, food science, etc., can solve the problems that cannot meet the requirements of uniformly pulverized particles and high fiber content, and achieve simple structure, uniform granulation particle size and uniform distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

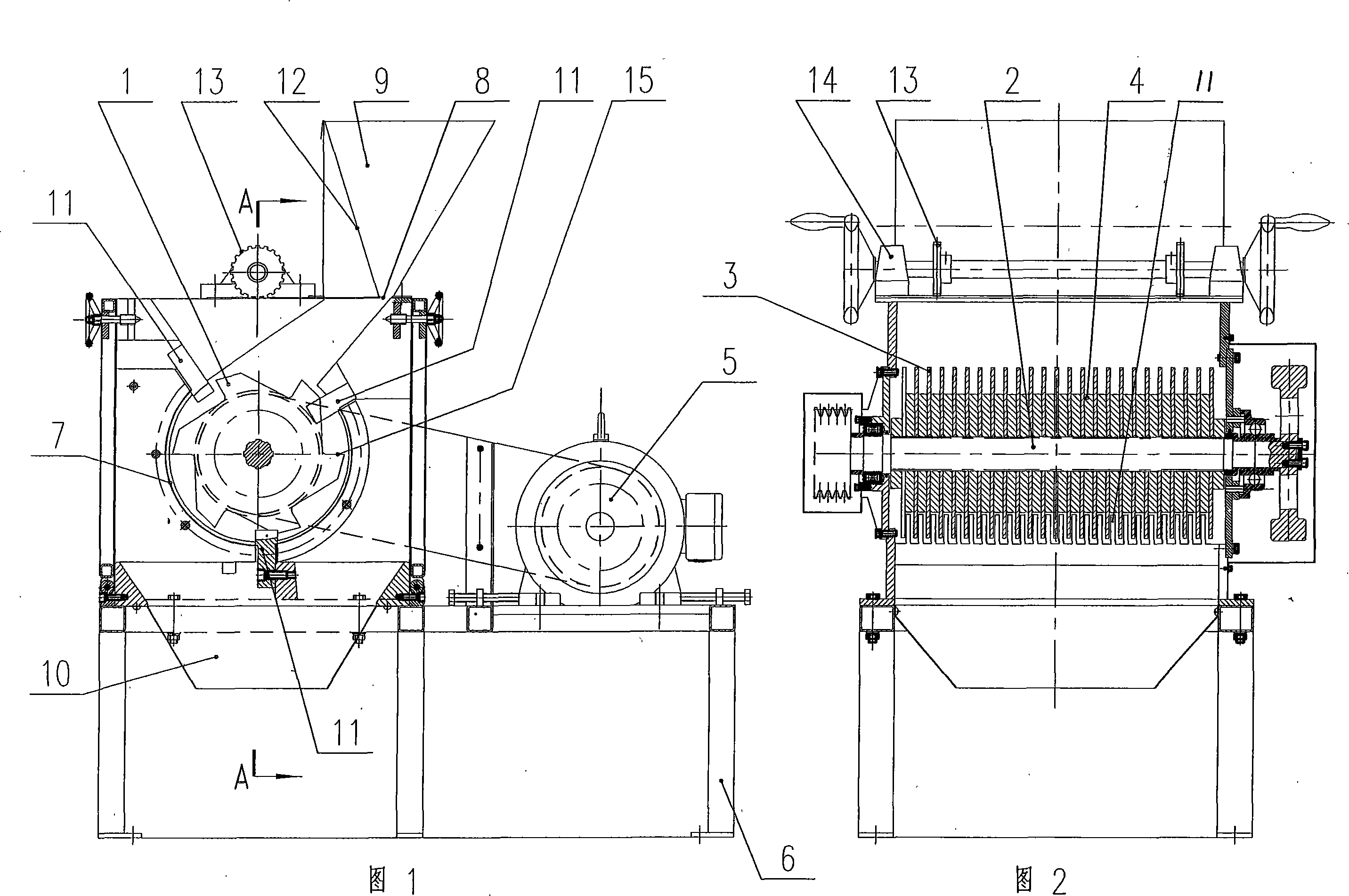

[0013] As shown in the figure, the present invention includes a frame 6 and a hob body installed on the frame. The hob body includes a horizontal rotating shaft 2 and a moving knife group 1 set on the rotating shaft. The moving knife group is a set of spacers. 4 separate blades 3 with cutting edge 15, the rotating shaft of the moving knife group is connected with the transmission device 5, a cylinder 7 with a mesh is installed on the outer cover of the moving knife group, and one or one The above comb tooth-shaped fixed knife 11, the comb teeth of the fixed knife and the blades of the moving knife group are interlaced and matched with each other. The top of the cylinder is provided with a material inlet 8, and the bottom is provided with a material outlet 10.

[0014] In the present invention, 4 to 16 cutting edges 15 are evenly provided on the outer circle of each blade 3; a hopper 9 is externally connected to the feed port of the cylinder 7, and a material guide plate 12 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com