Radar material level meter connecting structure

A technology of radar level gauge and connection structure, which is applied in the direction of aluminum compound, inorganic chemistry, liquid/fluid solid measurement, etc. Good effect, saving production cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

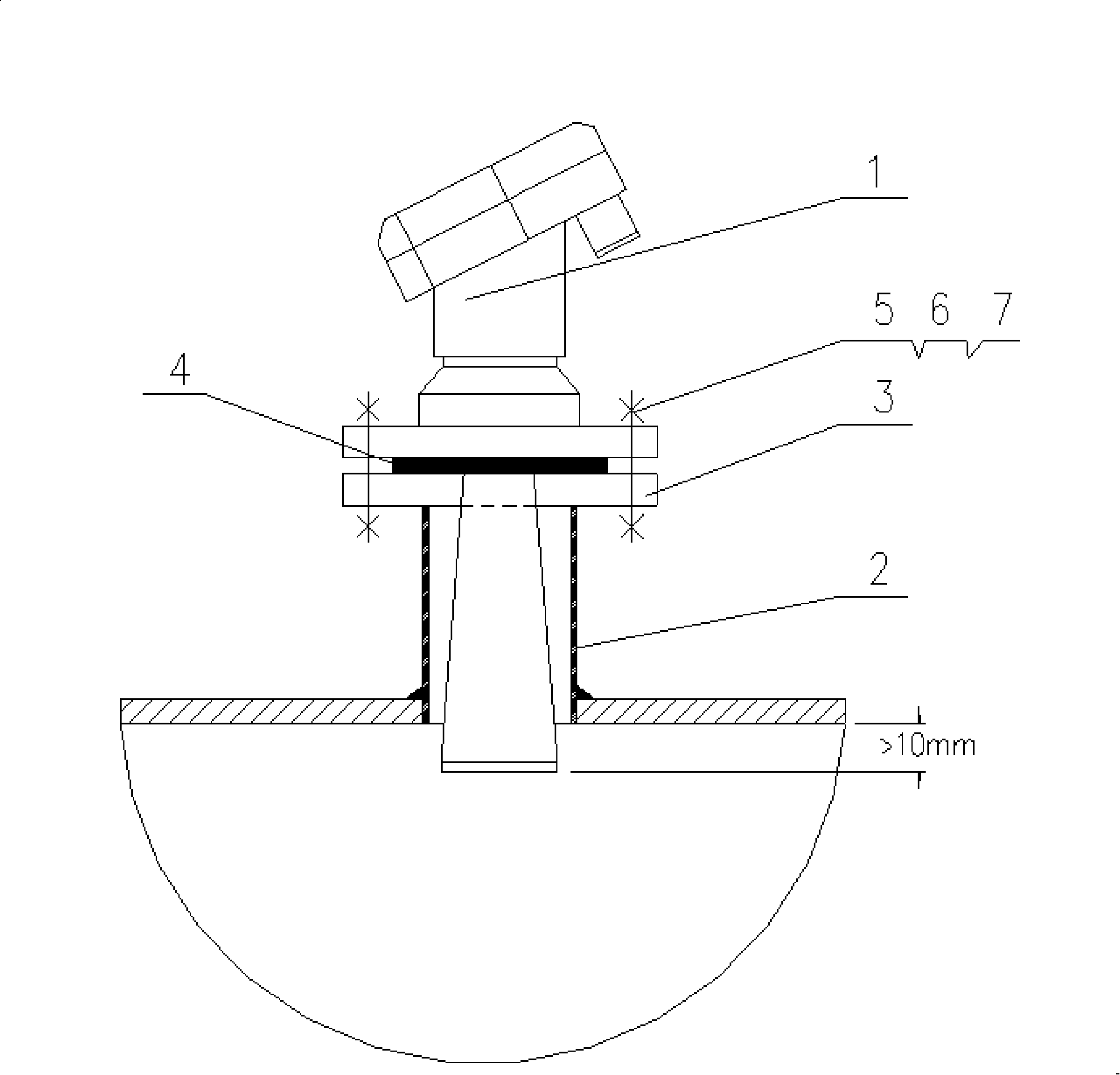

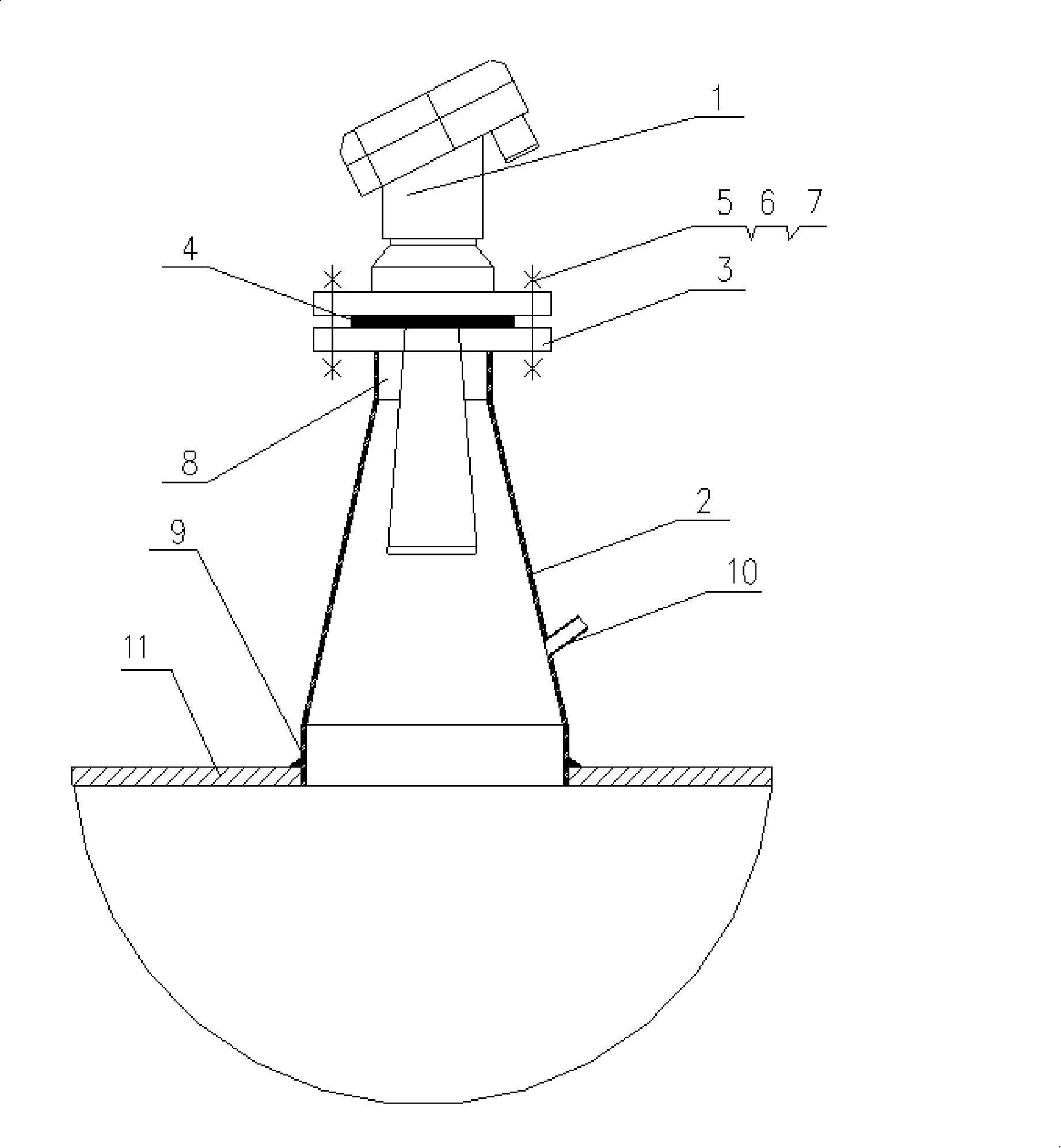

[0015] The embodiment of the present invention: According to the emission angle of the radar level gauge 1, a hole is opened on the top plate 11 of the storage tank for storing scarred liquid, and a short pipe 9 with a length of 100mm is welded, and the flange 3 connected with the level gauge is also welded in length. A 100mm short tube 8, between the two short tubes, a connecting tube 2 with a length of 600~800mm is welded. The connecting tube 2 is a tapered tube with a small head diameter of φ159mm at the upper end and a large diameter of φ450mm at the lower end. Weld an air purge tube 10 (located below the bottom of the radar level gauge 1) on the lower part of the slab, connect the radar level gauge 1 with the flange 3 through screws 5, nuts 6, and washers 7, and install a gasket 4 in the middle, The rest is the same as the prior art.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com