Device and method for testing and standardizing performance of macrotype over-loading operation equipment

A performance and equipment technology, applied in the field of machinery, can solve the problems of late start, no performance testing device and method for large-scale heavy-duty operation equipment, etc., and achieve the effects of easy control, rapid performance testing and detection, and good stress characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

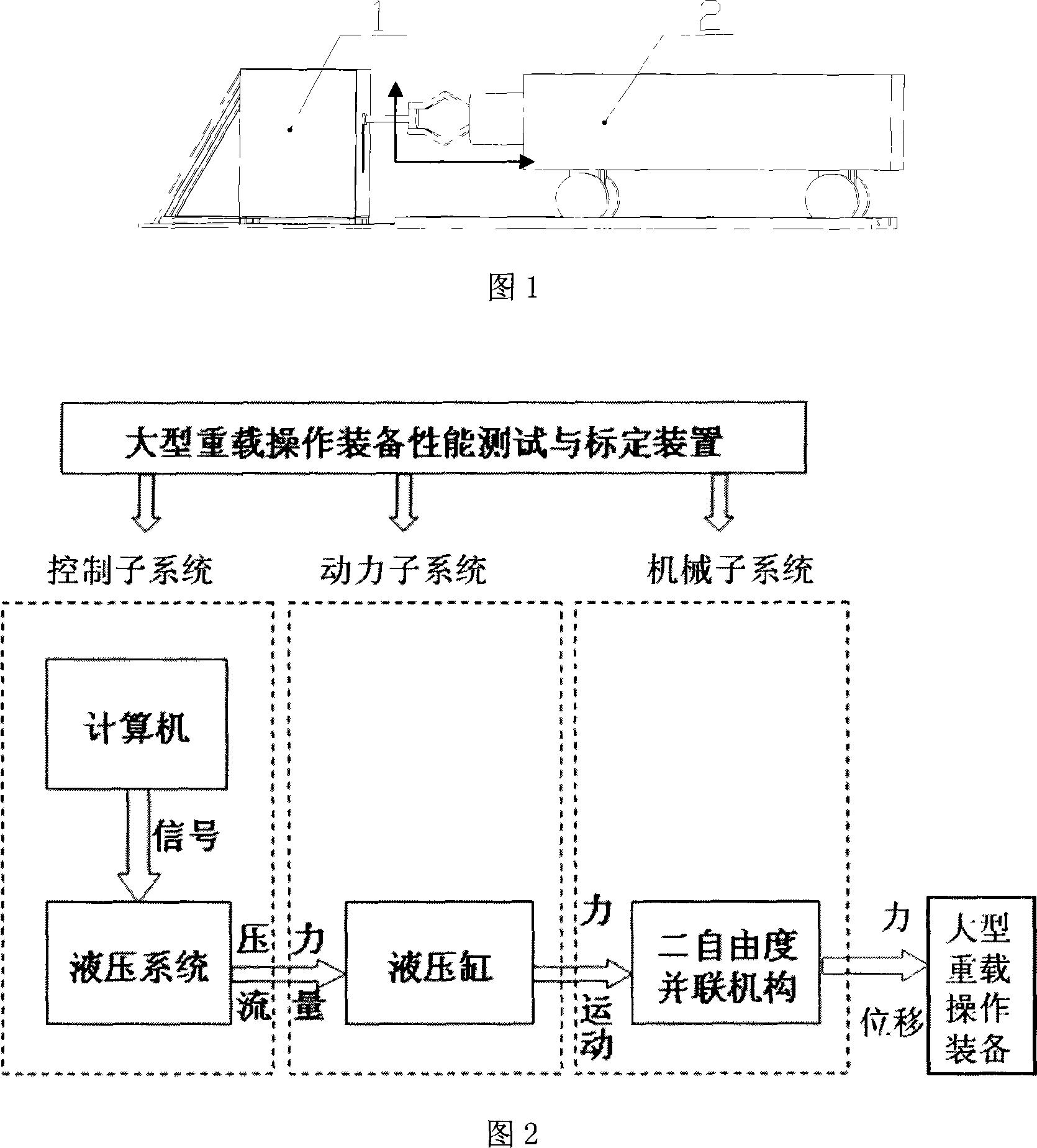

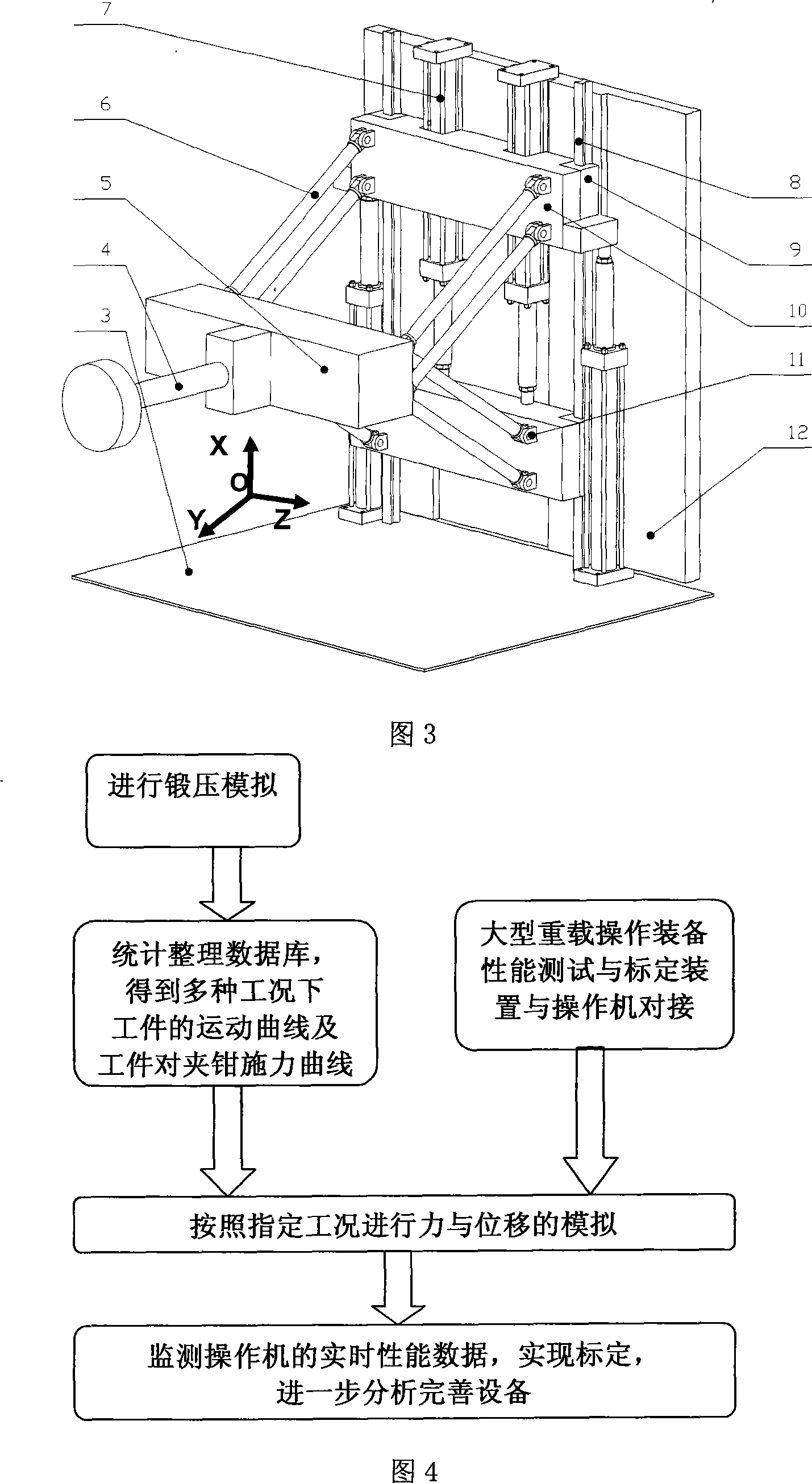

[0026] Embodiment 1: A typical embodiment of the present invention is shown in accompanying drawing 1, and this embodiment is used for simulating the movement of the workpiece and the force exerted by the workpiece on the clamp under forging conditions, so as to carry out large-scale heavy-duty operation equipment Performance testing and calibration.

[0027] Figure 1 is a layout diagram of the performance testing and calibration device 1 of the large-scale heavy-duty operating equipment and the forging manipulator (prototype) 2. As shown in Figure 1, the arrow indicates the movement and force of the end effector of the performance testing and calibration device 1 of the large-scale heavy-duty operating equipment Direction, large-scale heavy-duty operation equipment performance testing and calibration device 1 and forging operation machine 2 are on the same platform.

[0028] As shown in FIG. 2 , the performance testing and calibration device 1 for large-scale heavy-duty opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com