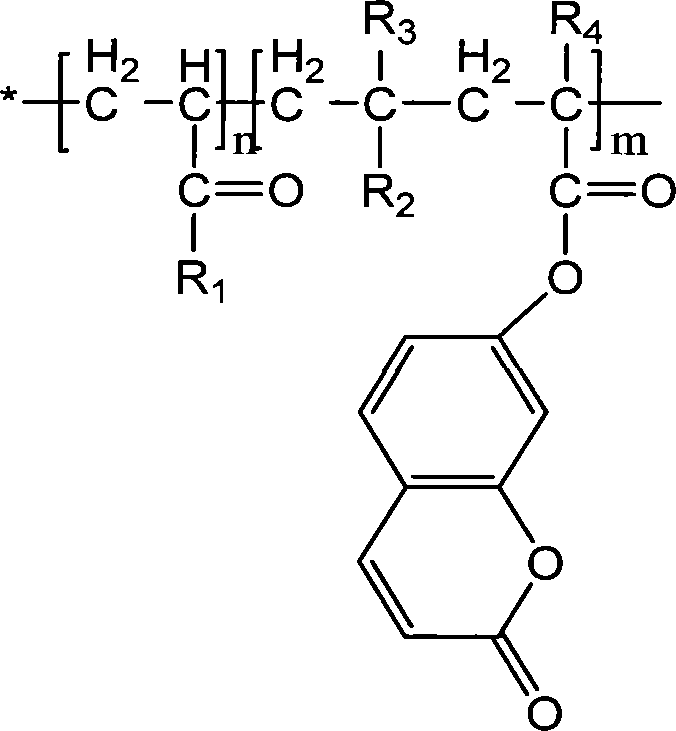

Multiple environment-responsive di-block copolymer and preparation method thereof

An environmentally responsive, block copolymer technology, applied in the field of multiple environmentally responsive two-block copolymers and their preparation, can solve problems such as not being able to reflect the properties of polymers well, and achieve the effect of wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

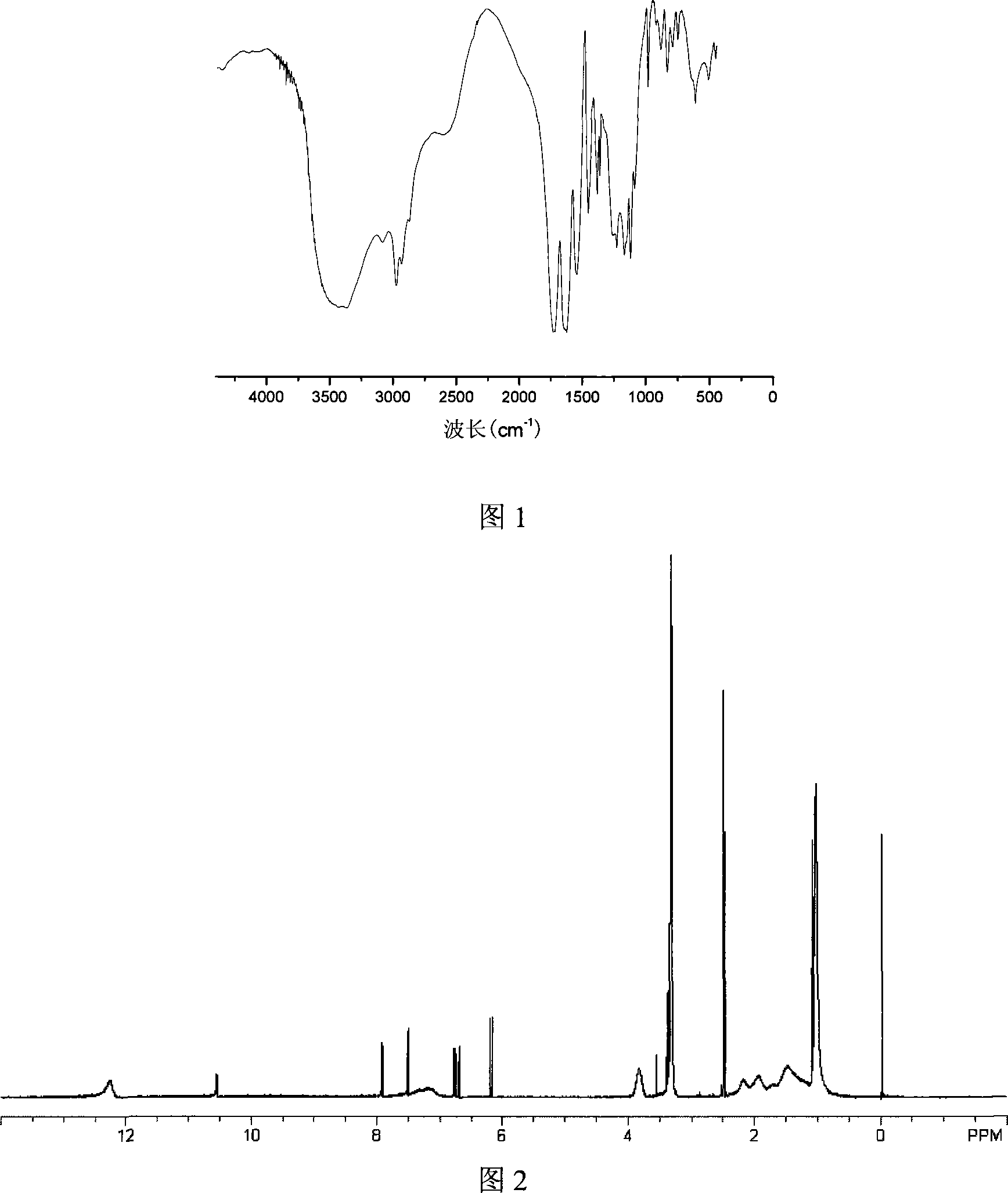

Method used

Image

Examples

Embodiment 1

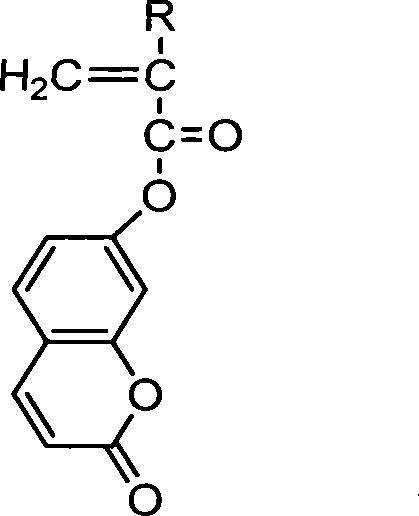

[0021] (a) In a three-necked flask with stirring, add 20mlDMF, 75mmol (7.67g) triethylamine and 30mmol (4.86g) 7-hydroxycoumarin, at 0°C, pass through N 2 For protection, a solution of 75 mmol (7.84 g) of methacryloyl chloride in 20 ml of DMF was added dropwise, the rate of addition was controlled, and the addition was completed within 1 hour. The reaction was continued at 0° C. for 1 hour, and then the system was heated to room temperature for another 3 hours. After the reaction, the reaction solution was filtered to remove triethylamine hydrochloride, and then precipitated into 400ml of ether, stirred at room temperature for 5 hours, filtered and washed with ether, and vacuum-dried at 40°C for 48 hours to obtain methacrylic acid resin. Soybein ester (CMA).

[0022] (b) Dissolve 0.02g of AIBN, 0.13g of phenylethyl dithiobenzoate, and 7.00g of isopropylacrylamide (NIPAAm) in 25ml of 1,4-dioxane, and react at 60°C for 80 Hour. After the reaction, the solution was poured into...

Embodiment 2

[0027] (a) In a three-necked flask with stirring, add 20mlDMF, 75mmol (7.67g) triethylamine and 30mmol (4.86g) 7-hydroxycoumarin, at 0°C, pass through N 2 For protection, a solution of 75 mmol (7.84 g) of methacryloyl chloride in 20 ml of DMF was added dropwise, the rate of addition was controlled, and the addition was completed within 1 hour. The reaction was continued at 0° C. for 1 hour, and then the system was heated to room temperature for another 3 hours. After the reaction, the reaction solution was filtered to remove triethylamine hydrochloride, and then precipitated into 400ml of ether, stirred at room temperature for 5 hours, filtered and washed with ether, and vacuum-dried at 40°C for 48 hours to obtain methacrylic acid resin. Soybein ester (CMA).

[0028] (b) Dissolve 0.02g of AIBN, 0.18g of phenylethyl dithiobenzoate, and 8.00g of isopropylacrylamide (NIPAAm) in 30ml of 1,4-dioxane, and react at 80°C for 50 Hour. After the reaction, the solution was poured into...

Embodiment 3

[0031] (a) In a three-necked flask with stirring, add 20mlDMF, 75mmol (7.67g) triethylamine and 30mmol (4.86g) 7-hydroxycoumarin, at 0°C, pass through N 2For protection, a solution of 75 mmol (7.84 g) of methacryloyl chloride in 20 ml of DMF was added dropwise, the rate of addition was controlled, and the addition was completed within 1 hour. The reaction was continued at 0° C. for 1 hour, and then the system was heated to room temperature for another 3 hours. After the reaction, the reaction solution was filtered to remove triethylamine hydrochloride, and then precipitated into 400ml of ether, stirred at room temperature for 5 hours, filtered and washed with ether, and vacuum-dried at 40°C for 48 hours to obtain methacrylic acid resin. Soybein ester (CMA).

[0032] (b) Dissolve 0.02g of AIBN, 0.26g of phenylethyl dithiobenzoate, and 7.00g of isopropylacrylamide (NIPAAm) in 30ml of 1,4-dioxane, and react at 90°C for 40 Hour. After the reaction, the solution was poured into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com