Early strength type polycarboxylic acid series high-performance water reducing agent and method for manufacturing same

A polycarboxylate-based, high-performance technology, applied in the field of early-strength polycarboxylate-based high-performance water reducers, can solve the problems of failure to adjust and improve the formulation of polycarboxylate products, single product type, etc., and achieve early-strength Remarkable performance, speeding up construction progress and improving efficiency of use

Inactive Publication Date: 2010-06-09

LETS HLDG GRP CO LTD +1

View PDF2 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Although some admixture manufacturers have industrialized the production of polycarboxylic acid-based high-efficiency water reducers, the production method is concentrated on the process of first esterification and then copolymerization, and the product type is relatively single, and it is not possible to produce polycarboxylic acid products according to actual application needs. Recipe tweaks and improvements

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] The concrete development process of the present invention and content are as follows:

[0024] 1. Experimental equipment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Login to View More

Abstract

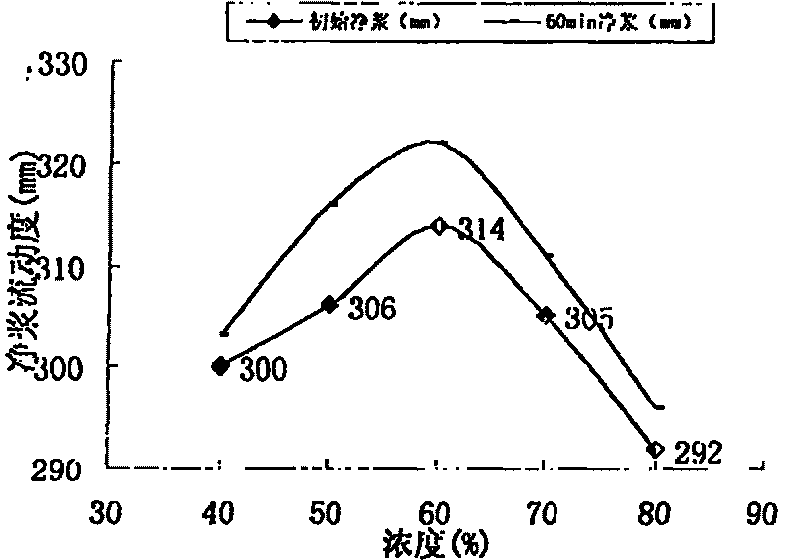

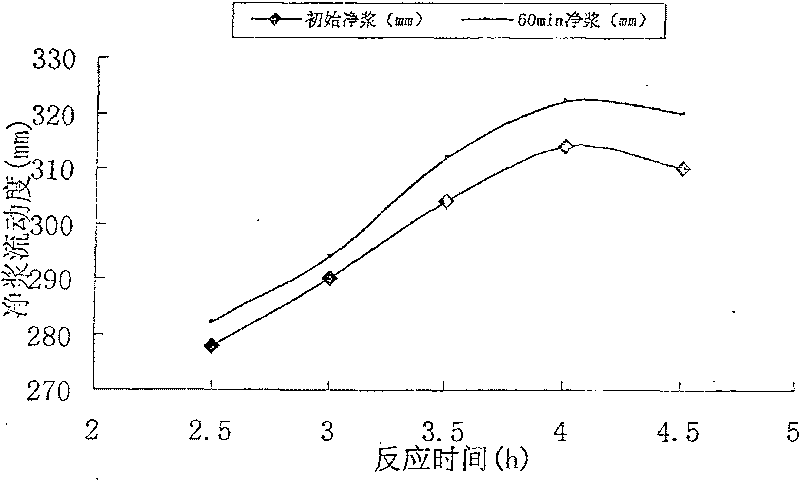

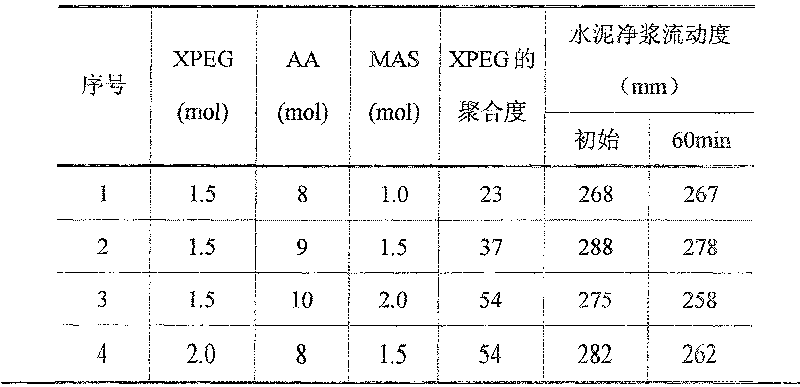

The invention proposes a compounding formula and manufacture method of an early-strength polyocarboxy acid high performance water reducing agent. The compounding formula is as follows: (1) the mass ratio of 37 61.5percent allyl polyethyleneoxide ether water-soluble fluid with polymerization degree 37, allyl polyethyleneoxide ether, acrylic acid, 27.7percent acrylic amide water-soluble fluid, 26.2percent methyl propylene sulfonic acid sodium water-soluble liquid is 2321:882:311:276.7:542.2; (2) the consumed amount of the initiator hydrogen peroxide is 0.2percent of a monomer mole number; (3) the initiator Sodium bisulfoxylate is 0.06percent of a monomer mole number; (4) the five elements copolymerization is carried on in the 60percent density system under 55 DEG C. The invention synthesizescarboxylic acid series product with strong early-strength performance, which especially are used for increasing the early-strength of the concrete largely under the low temperature of the winter to speed up the concrete construction progress and enhance the use efficiency of the construction template though the adjustment of the formula and craft. The invention is suitable for the concrete project with high requirements for the concrete early-strength (within 2 days).

Description

technical field [0001] The invention relates to an early-strength polycarboxylate high-performance water reducer applied to concrete and a manufacturing method thereof. Background technique [0002] For concrete projects that have high requirements for the early strength of concrete (within 2 days), especially for concrete in low temperature environments, especially winter construction, it is necessary to add early-strength polycarboxylate high-performance water reducers to the concrete to ensure that the concrete early strength. At present, the synthesis reaction of this high-efficiency water reducer includes two steps: the first step is to generate polymerizable structural units; the second step is to generate a certain performance of polymer water reducing by condensation or addition polymerization. agent. [0003] Although some admixture manufacturers have industrialized the production of polycarboxylic acid-based high-efficiency water reducers, the production method i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B24/24C08F216/16C08F220/56C04B103/30

CPCC04B24/2641C04B2103/302C04B2103/10

Inventor 于飞宇麻秀星郭鑫祺蔡永太

Owner LETS HLDG GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com