Method for preparing high-quality red lead by lead slime of lead-acid batteries

A waste lead-acid battery, high-quality technology, applied to the removal of lead red, solid waste, lead oxide, etc., can solve the problems of lead dust escape labor intensity, high equipment investment, etc., to save metal lead resources and shorten roasting time , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

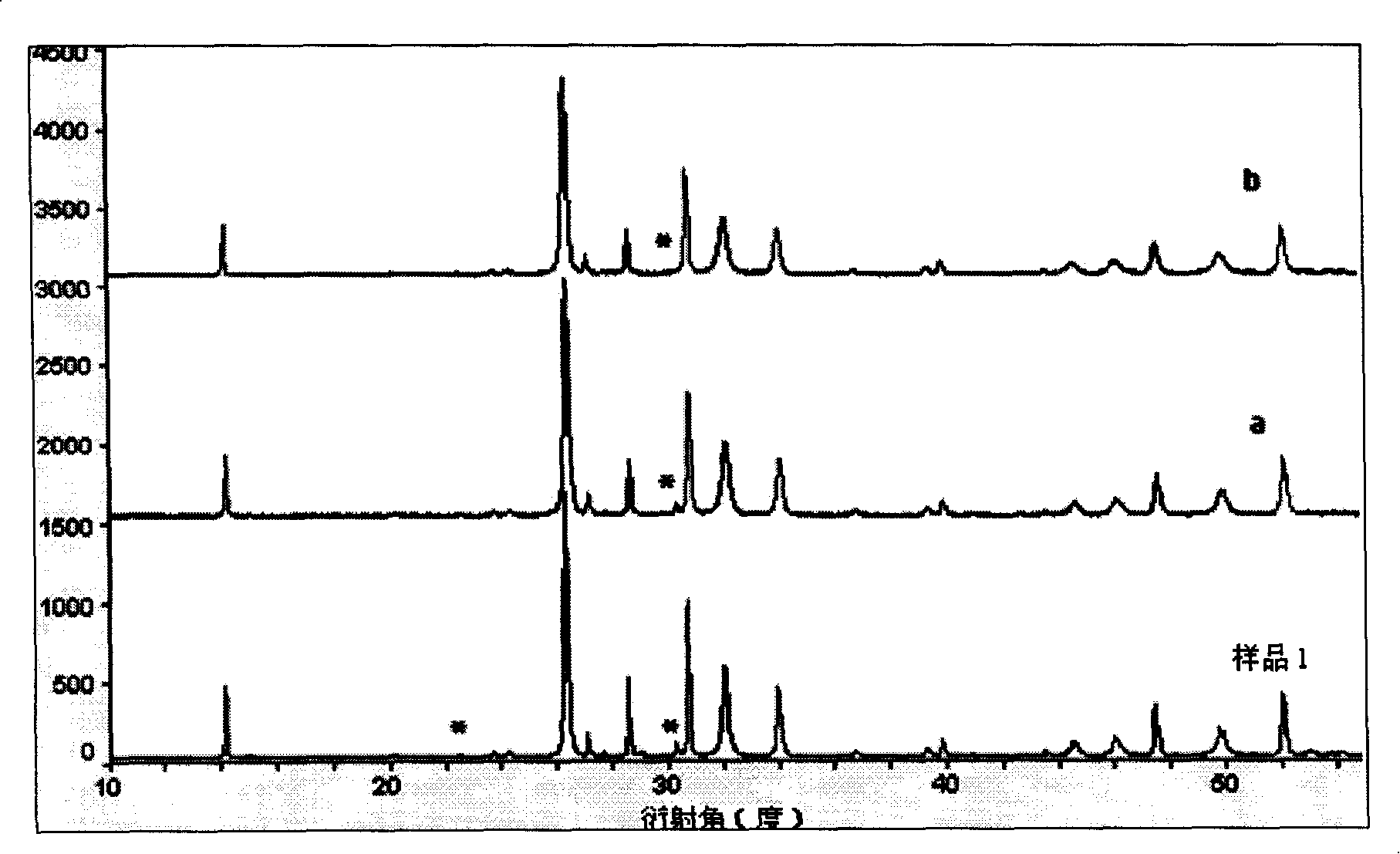

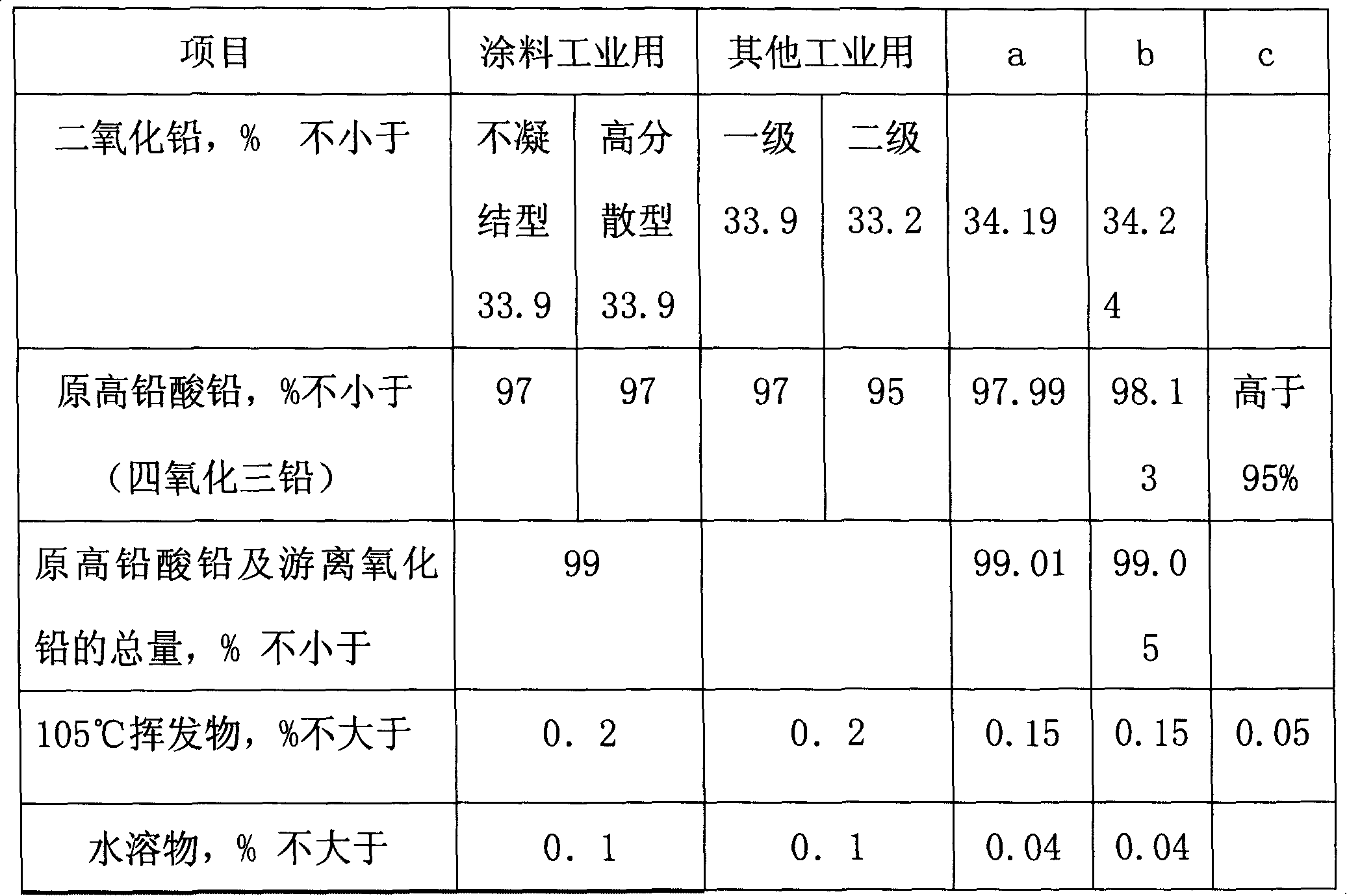

[0026] Example 1: After the lead slime is taken out from the storage battery, the anode and cathode are mixed together, washed repeatedly until neutral, then dried, and ground to 200-300 mesh powder. Dissolve 500 grams of sodium hydroxide and 40 grams of polyvinyl alcohol dispersant with a molecular weight of 120,000-150,000 in 3,100 grams of water, then add 1,000 grams of the above-mentioned lead mud powder, stir and react at 80°C for 2 hours, filter and separate, and use for filter cakes Wash with water repeatedly until neutral. After the obtained desulfurized lead-containing solid matter is dried, it is laid flat in a muffle furnace, the thickness of the flat bed is 5 cm, and it is fired at 470 ° C for 3 hours to obtain high-quality red lead. The lead recovery in the whole process is 95%, the content of the obtained lead peroxide (trilead tetraoxide) is as high as 97.99%. The product is tested and identified by X-ray diffraction (XRD) method, chemical analysis method accor...

Embodiment 2

[0027] Embodiment 2: the lead mud is dried after repeated washing to neutrality, and ground to 200-300 purpose powder; 150 grams of sodium hydroxide and 12 grams of polyvinyl alcohol dispersant with a molecular weight of 120000-150000 are dissolved in 2330 grams of water, and then Add 1000 grams of the above-mentioned lead slime powder, stir and react at 80°C for 2 hours, filter and separate, and wash the filter cake repeatedly with clear water until neutral. After the obtained desulfurized lead-containing solid matter is dried, it is laid flat in a muffle furnace with a thickness of 5 cm, and it is fired at 470 ° C for 3 hours, and the color of the obtained red lead is light red, and the crystal phase purity and color All worse than the red lead sample obtained in Example 1, the content of the obtained lead peroxide (trilead tetroxide) is only 84.07%.

Embodiment 3

[0028] Embodiment 3: Mud is dried after repeated washing to neutrality, and ground to 200-300 mesh powder; 1000 grams of sodium hydroxide and 50 grams of polyvinyl alcohol dispersant with a molecular weight of 120000-150000 are dissolved in 4100 grams of water, and then added 1000 grams of the above-mentioned lead slime powder, at a reaction temperature of 60°C and a reaction time of 6h, after the resulting desulfurized lead-containing solid matter is dried, it is laid flat in a muffle furnace with a thickness of 5 cm, and incubated at 470°C. Burn 3h, the obtained red lead sample is about 10 microns through particle size analysis average particle size, and the color of the obtained red lead is dark red, and the sample is identified through chemical analysis, and the obtained original high acid lead (trilead tetroxide) The content is only 92.45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com