Electrode with progressive structure of proton exchanging film fuel battery and method for making the same

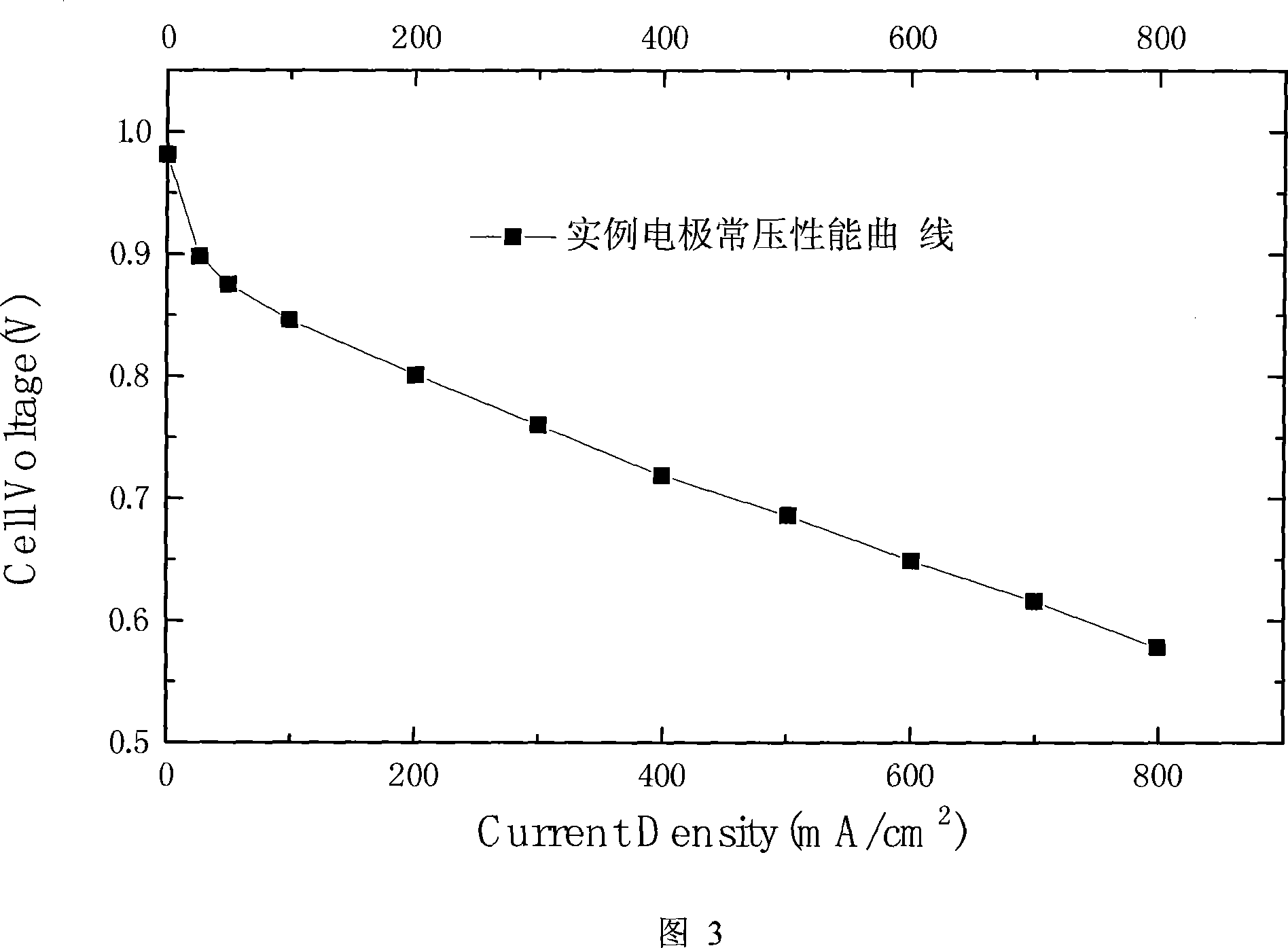

A proton exchange membrane and fuel cell technology, which is applied to fuel cell components, solid electrolyte fuel cells, battery electrodes, etc., can solve the problems of high gas transfer resistance and low catalyst utilization rate, and reduce mass transfer resistance, Enhanced gas channel continuity and reduced gas transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

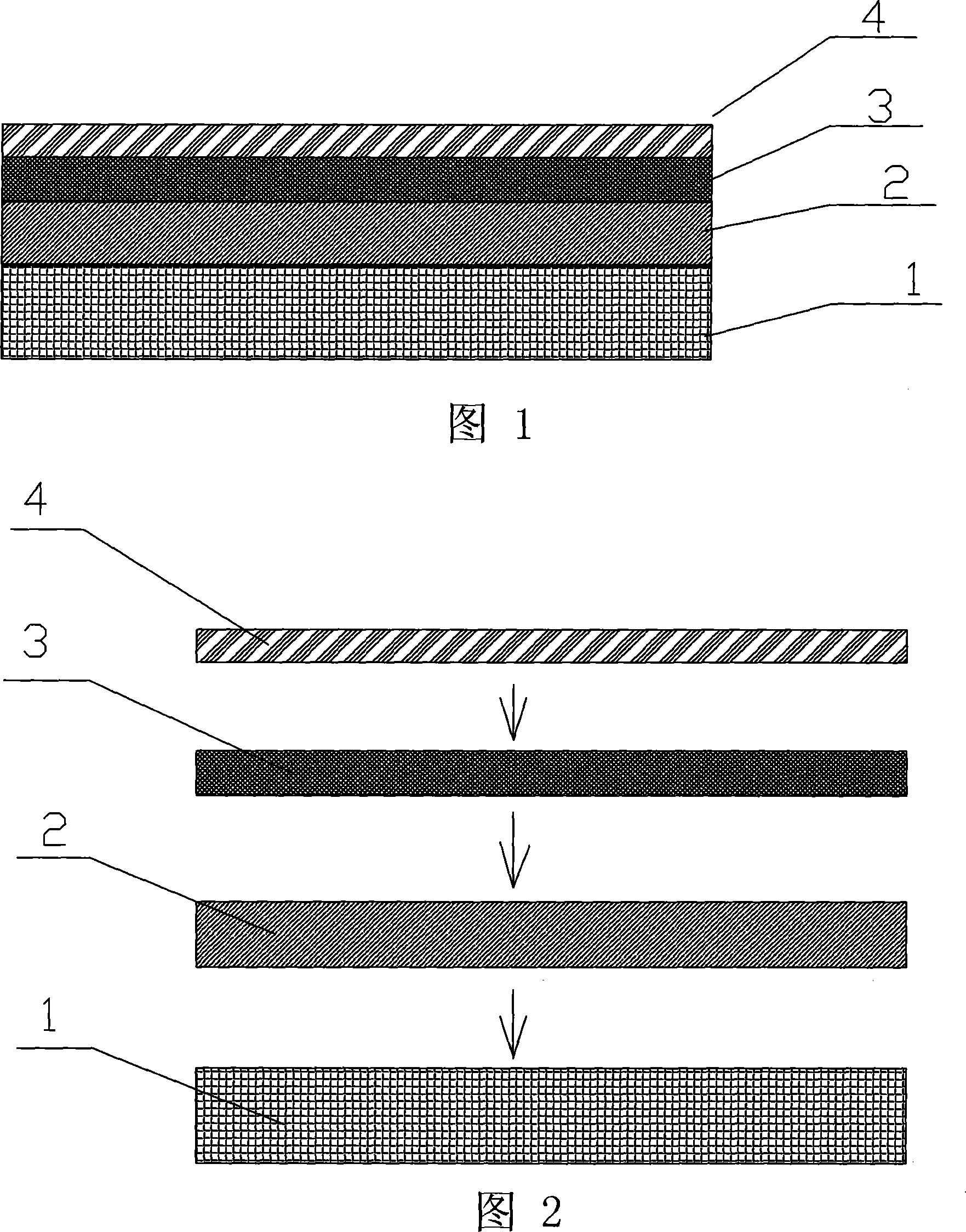

[0025] 1. Take Toray carbon paper and dip it in 3% PTFE emulsion to increase it to 8%. Baking at 340°C in a firing furnace.

[0026] 2. Mix acetylene black, pore-forming agent, PTFE and isopropanol, and stir evenly in an ultrasonic wave, and apply the above mixture evenly on the surface of the carbon paper. The amount of carbon powder in the ingredients is 1.0mg / cm 2 , PTFE accounts for 30% of the total, pore-forming agent accounts for 50%, and isopropanol is in an appropriate amount.

[0027] 3. Mix 40% Pt / C catalyst, pore-forming agent, PTFE and isopropanol, stir evenly in ultrasonic wave, and apply it to the completed leveling layer by hand. The amount of catalyst is 0.5mg / cm 2 , PTFE accounts for 30% of the total, and pore-forming agent accounts for 50%. The prepared hydrophobic electrode was baked at a constant temperature of 340° C. for 40 minutes.

[0028] 4. Spray the uniformly mixed material of 50% Pt / C catalyst, 5% Nafion solution and isopropanol onto the hydrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com