Method for producing L-threonine

A technology of threonine and culture method, applied in the direction of animal feed, additional food elements, animal feed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

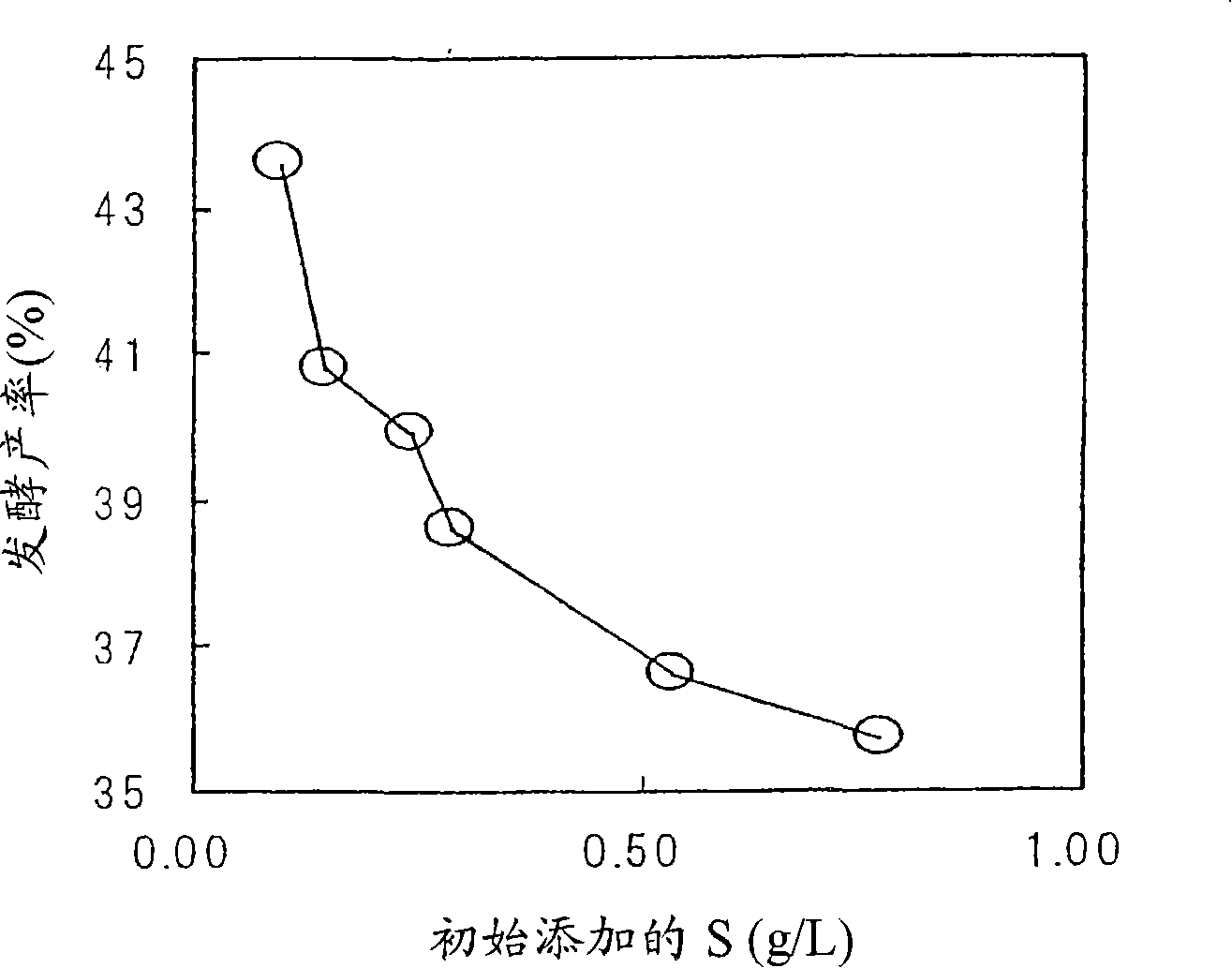

[0106] Example 1: Effect of Adjustment of Initial Sulfur Addition in Fed-Batch Culture

[0107] First, in fed-batch culture, the effect of limiting sulfur in the main culture initial medium to a predetermined concentration or lower during L-threonine production was examined.

[0108] Cultivate the VKPM B-5318 strain on LB agar medium plate (10g / L tryptone, 5g / L yeast extract, 5g / L NaCl, 15g / L agar) containing 20mg / L streptomycin sulfate at 37°C 24 hours, scrape off 1 / 10 of the cells on the plate from one plate and inoculate into 50 mL LB medium containing 20 mg / L streptomycin sulfate (10 g / L tryptone, 5 g / L yeast extract, 5g / L NaCl), at 40°C and 144rpm for 6 hours seed culture.

[0109] After completion of the seed culture, a seed culture medium in a volume equivalent to 16% of the volume of the main culture medium was inoculated into a 1-L small fermenter containing 300 mL of the main culture medium, and cultured at 40° C. and pH 7.0. The composition of the main culture me...

Embodiment 2

[0125] Example 2: Effect of adjustment of sulfur in the feed medium in fed-batch culture

[0126] First, in the same manner as in Example 1, the VKPM B-5318 strain was placed on the LB agar medium plate containing 20 mg / L streptomycin sulfate (10 g / L tryptone, 5 g / L yeast extract, 5 g / L L NaCl, 15g / L agar) at 37°C for 24 hours, scrape off 1 / 10 of the cells on the plate from a plate, and inoculate 50 mL of LB culture containing 20 mg / L streptomycin sulfate in a baffled flask Seed culture was carried out at 40° C. and 144 rpm for 6 hours in medium (10 g / L tryptone, 5 g / L yeast extract, 5 g / L NaCl).

[0127] After completion of the seed culture, a seed culture medium in a volume equivalent to 16% of the volume of the main culture medium was inoculated into a 1-L small fermenter containing 300 mL of the main culture medium, and cultured at 40° C. and pH 7.0. The main culture medium had the same components as those used in Example 1.

[0128] The culture was adjusted to pH 7.0 du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com