Device for simulating weak joint defect of diffusion weld interface

A diffusion welding and interface technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problem of difficulty in obtaining ultrasonic signals, and achieve the effect of ensuring the quality of diffusion welding and improving the detection rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

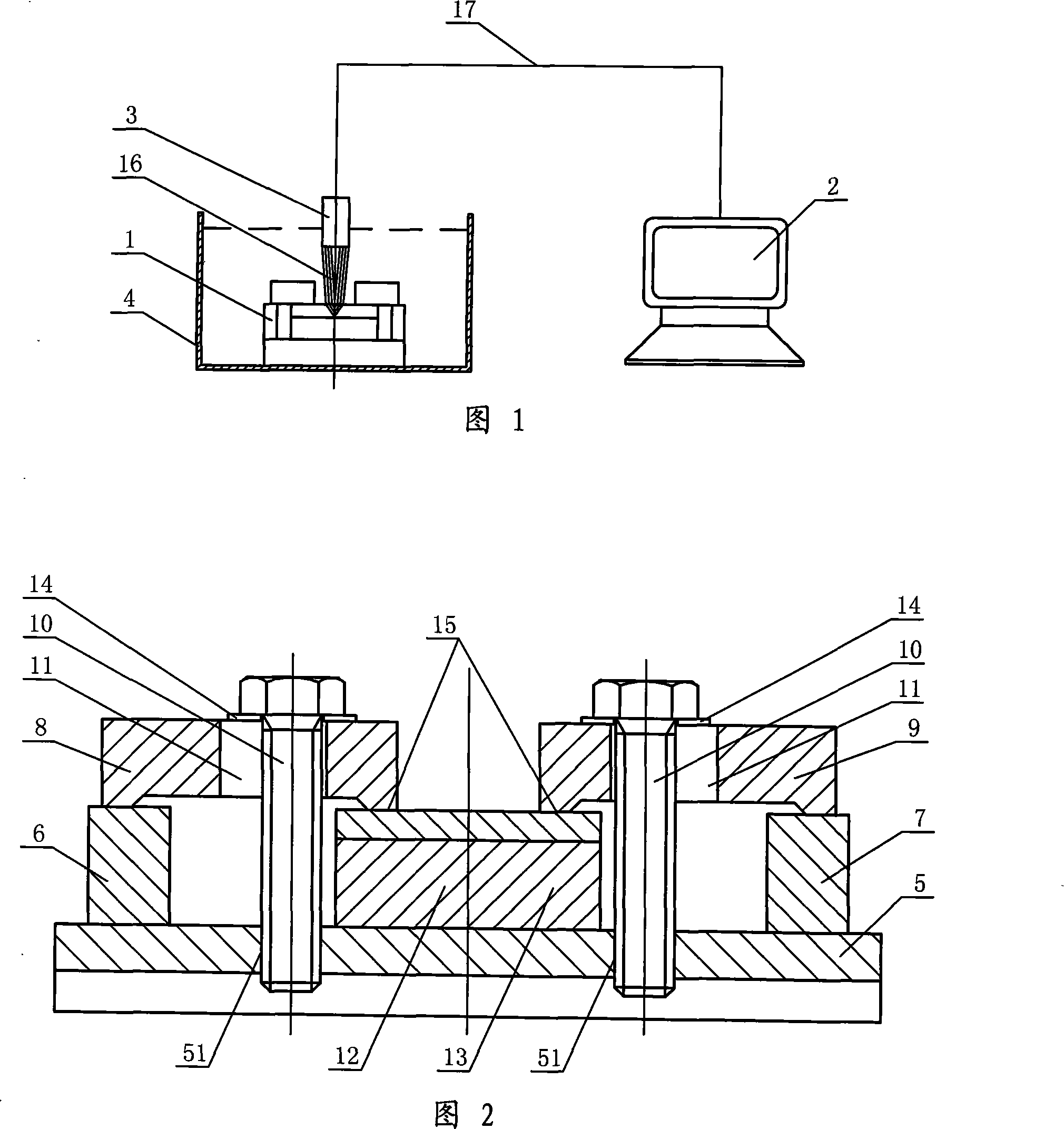

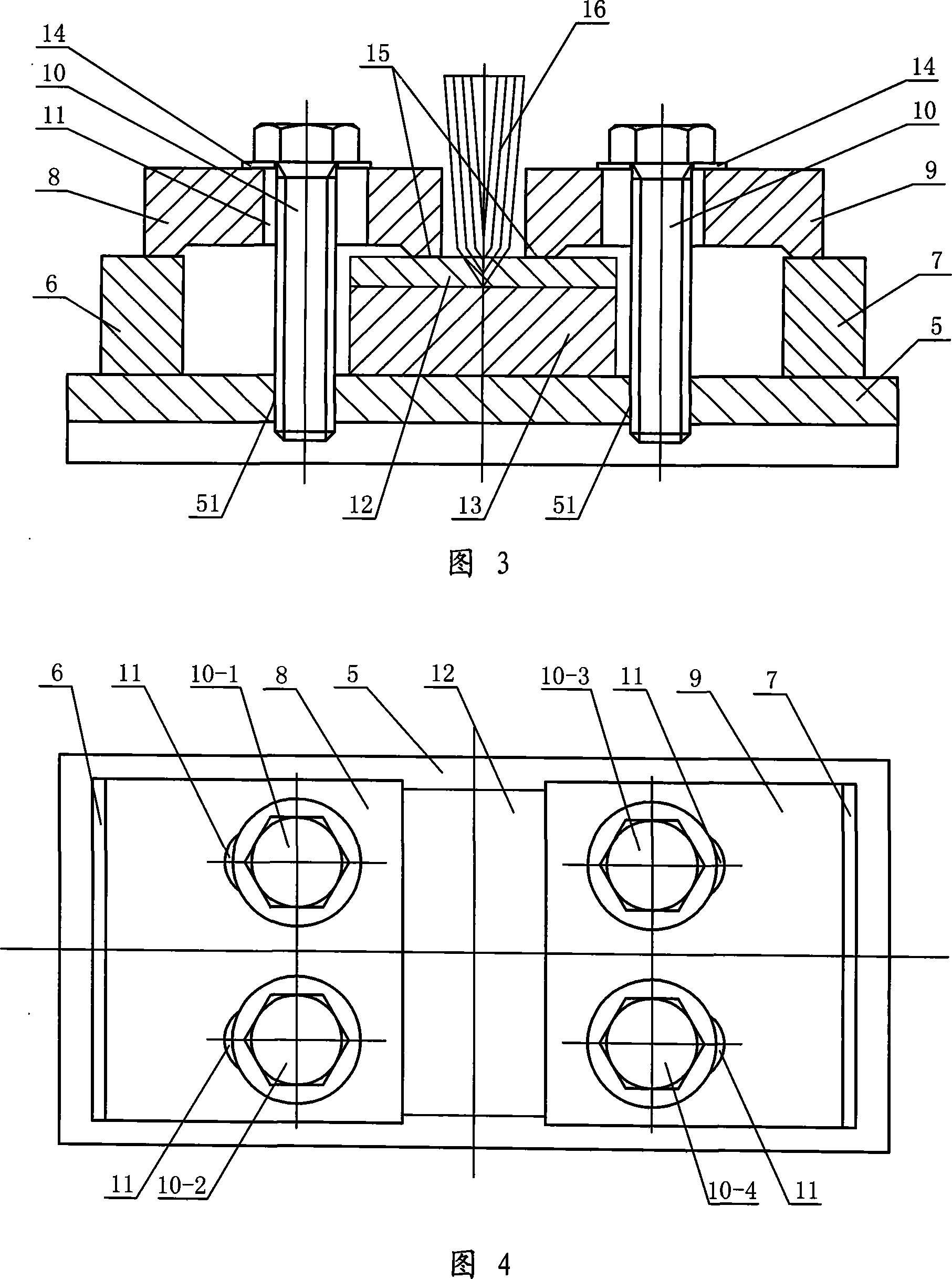

[0007] Specific Embodiment 1: This embodiment is described in conjunction with Fig. 1 and Fig. 2. This embodiment is composed of a compression device 1, an ultrasonic signal acquisition device 2, a probe 3 and a water tank 4. The compression device 1 consists of a bracket 5 and a left pad 6 , right spacer 7, left pressure piece 8, right pressure piece 9 and four fastening bolts 10, left spacer 6 and right spacer 7 are respectively arranged on both sides of the upper end surface of bracket 3, and the upper end of left spacer 6 A left pressing block 8 is provided, a right pressing block 9 is provided on the upper end of the right cushion block 7, a transverse through hole 11 is arranged on the left pressing block 8 and the right pressing block 9, and the threaded end of the fastening bolt 10 passes through the transverse through hole 11 Fastened in the threaded hole 51 on the bracket 5, a gasket 14 is provided between the fastening bolt 10 and the left pressing block 8 or the rig...

specific Embodiment approach 2

[0008] Embodiment 2: This embodiment is described in conjunction with FIG. 2 . In this embodiment, the lower end surfaces of the left pressing block 8 and the right pressing block 9 are provided with a pressure head 15, and the pressure head 15 converts the tightening force into a downward pressing force.

[0009] The method of the present invention to simulate the weak joint defects of different gaps in the diffusion welding interface is as follows:

[0010] (1). Simulate a very tight weak joint defect that is fitted: two methods can be used to realize the simulation of this defect, see Figure 3, the first method: the pressure on the left pressure block 8 and the right pressure block 9 The head 15 is placed close to the center of the diffusion welding sample, leaving only a space for the incidence of the ultrasonic sound beam 16 in the middle, and the force exerted by the indenter 15 is limited to the central area, so that the upper diffusion welding sample 12 and the lower si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com