Drill absorption pile structure and construction method thereof

A drill bit and drill pipe technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of high cost and long construction period, and achieve the effect of reducing piling cost, shortening construction progress, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

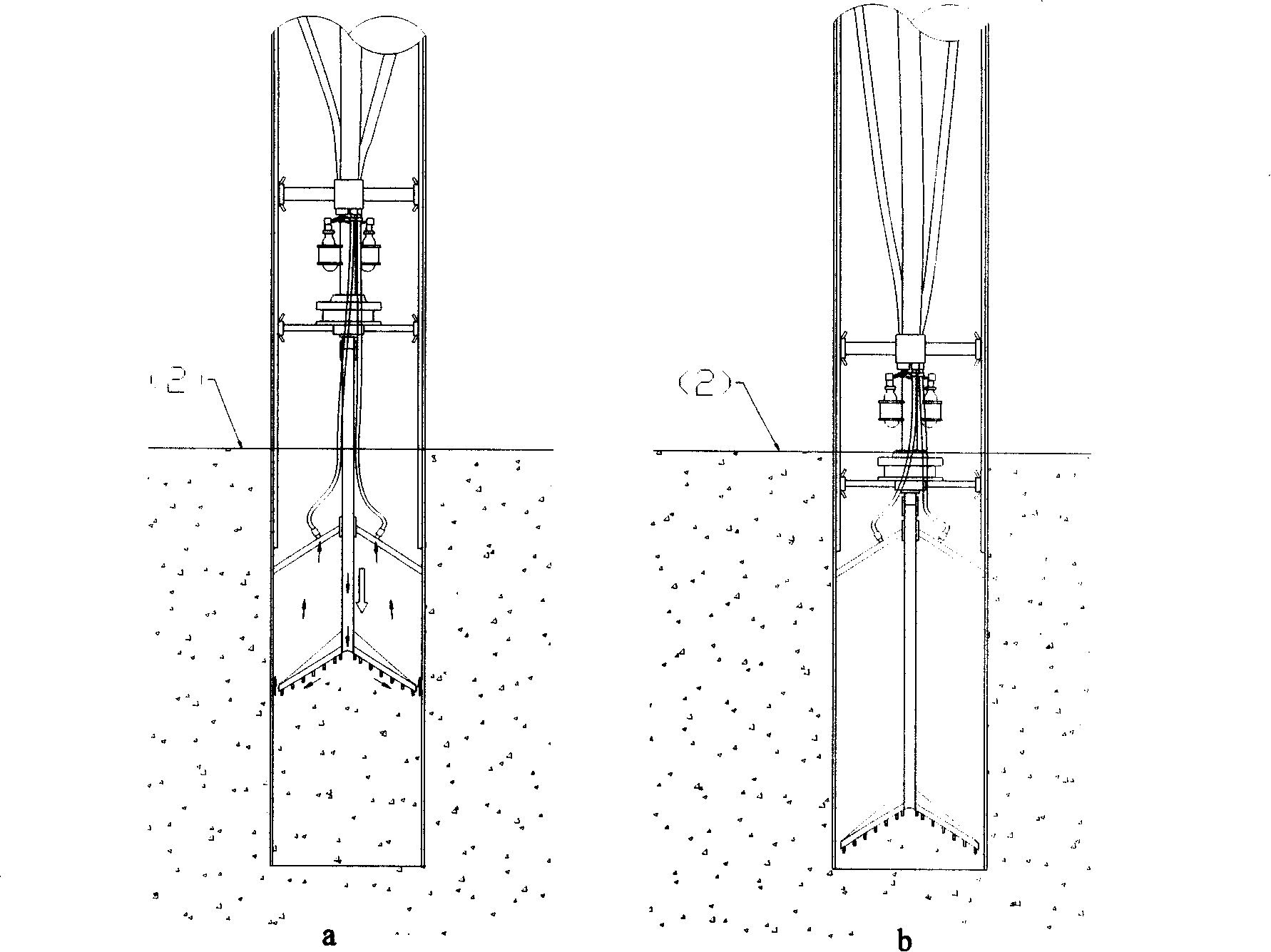

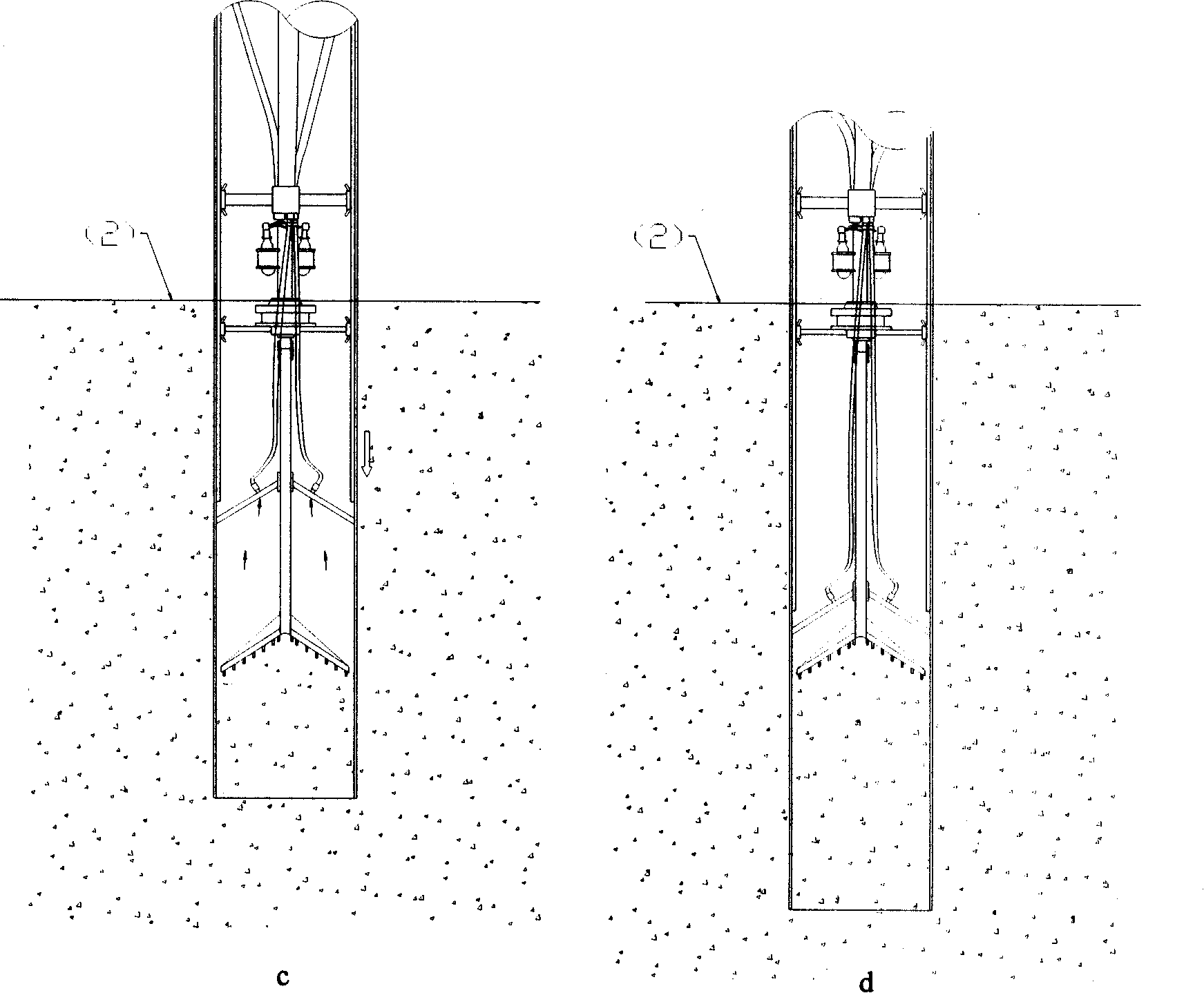

[0016] After the drilling and suction pile is positioned, it is hoisted into the sea and inserted into the mud surface (2), and the drill pipe is driven to rotate the drill bit to break through the soil and drill into the figure 2 as shown in a. Start the hydraulic motor (17) and the hydraulic high-pressure water pump (18), and the power shaft of the main engine hydraulic motor (17) of the immersed tube drilling rig drives the drill pipe (10) through the coupling (12) to rotate the inverted cone-shaped drill bit (11) Break through the ground. The soil broken by the drill bit and the high-pressure water form high-pressure mud such as figure 2 as shown in b. The hydraulic high-pressure water pump (18) for slurry discharge supplies high-pressure water to the bottom of the drill bit (11) through the central pipe of the drill pipe, and forms high-pressure mud from the soil and high-pressure water broken by the drill bit. The large-scale one-way valve (7) and the slurry dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com