A jacking process for an underwater cable-stayed floating tunnel

A suspension tunnel and cable-stayed technology, which is applied in the field of underwater suspension tunnels, can solve the problems of difficult construction, high cost, and difficulty in predicting comfort and safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with accompanying drawing.

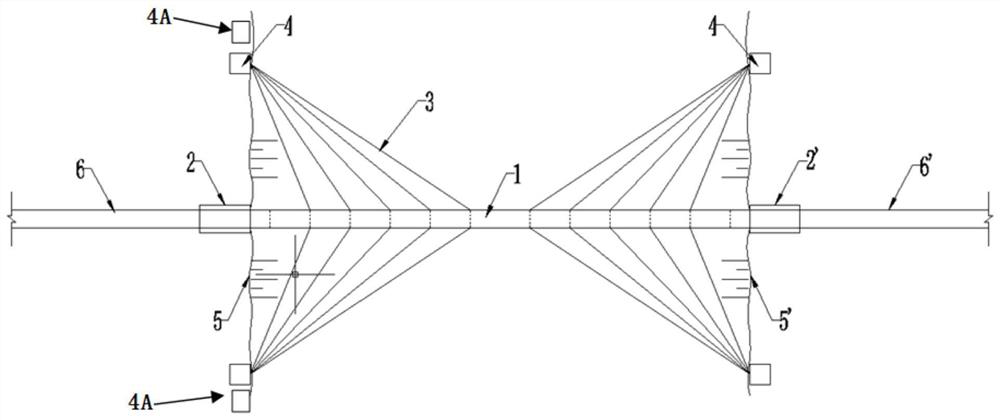

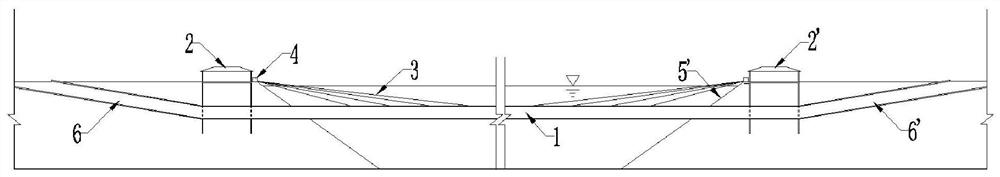

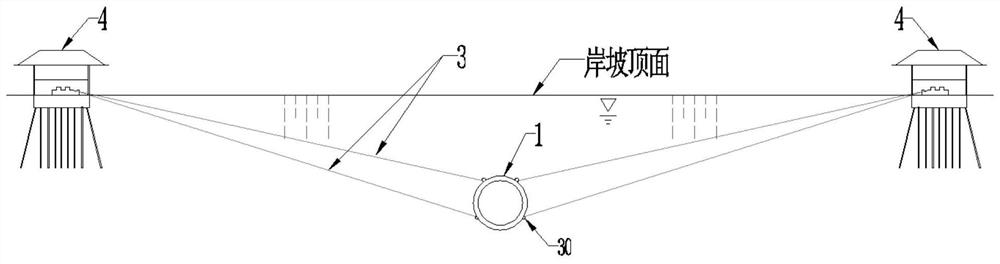

[0053] see Figure 1 to Figure 10 , the jacking process of the underwater cable-stayed floating tunnel of the present invention, the applicable floating tunnel includes the tunnel body, the pushing side shore structure 2, the receiving side shore structure 2', the cable anchorage system and the buoyant weight ratio adjustment system; Among them, the tunnel body includes the floating tunnel 1 in the water, the land slope tunnel 6 on the pushing side and the slope tunnel 6' on the receiving side; On the coast 5 and the coast 5' on the receiving side; the water-facing end of the land slope tunnel 6 on the pushing side and the water-facing end of the land slope tunnel 6' on the receiving side are connected to the shore structure 2 on the pushing side and the shore on the receiving side in one-to-one correspondence The backwater end of the structure 2' is connected; the underwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com