Full oxidized starch surface sizing technique

A technology of oxidized starch and surface sizing, which is applied in the field of papermaking industry, can solve problems such as unstable sizing material concentration, complex preparation process, and poor paper printing strength, so as to reduce the consumption of paper fibers, simplify the gluing process, and improve The effect of printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

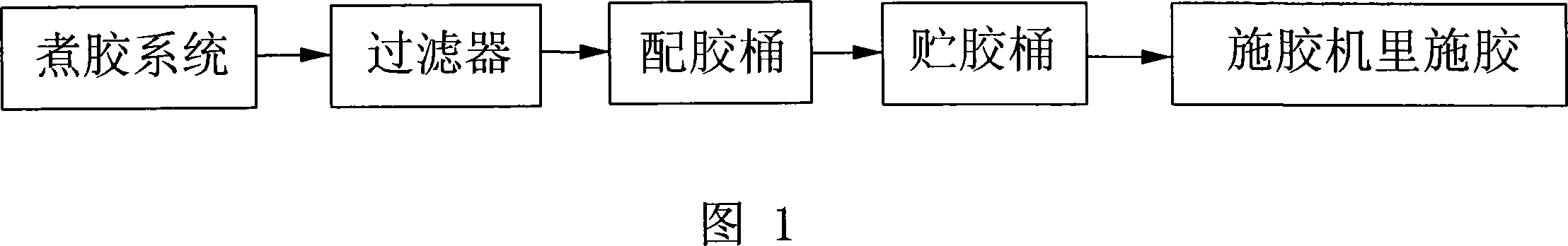

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] A kind of fully oxidized starch surface sizing process, referring to Figure 1, selects starch as raw material, and this starch raw material selects the oxidized starch produced with dry cassava for use, because the oxidized starch produced by dried cassava has less foam in the process of preparing starch glue , Good film-forming property, high strength and stable glue amount after paper glued.

[0017] The process steps are: first, the production of oxidized starch glue: add the oxidized starch raw material into warm water at a temperature of 30-40°C, then pour it into the glue cooking equipment for stirring to make a starch slurry, and then pass it into the starch slurry Enter saturated steam for heating, and stir while heating, so that the oxidized starch is evenly dispersed in the water; when the temperature reaches 90°C, heat for another 20-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com