Production method for alkyl sodium salicylate metallic detersive

A technology of sodium alkyl salicylate and metal detergent, which is applied in the field of lubricating oil, and can solve the problems of restricting the promotion and use of metal detergents and restricting the development of high-grade oil products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

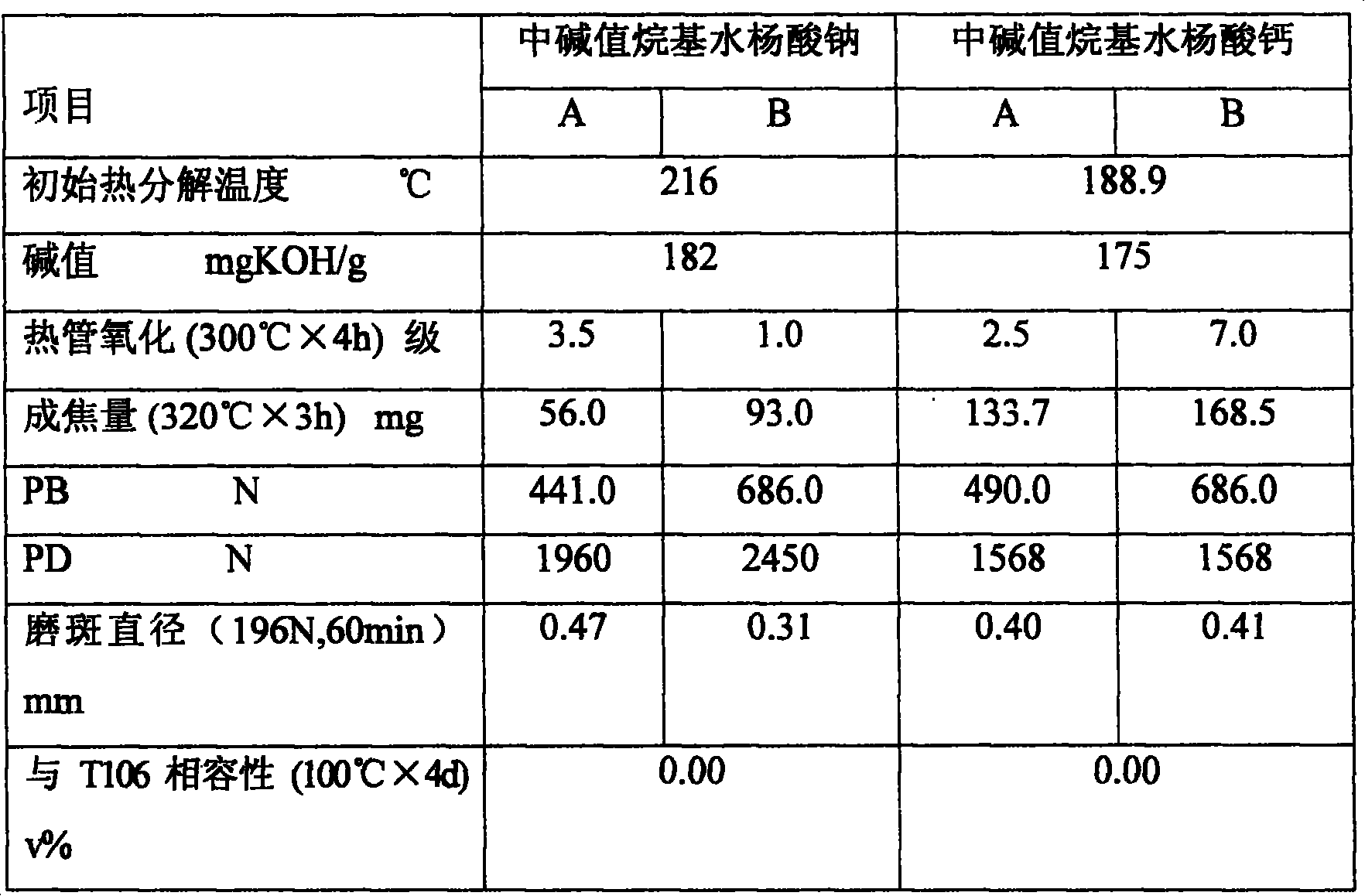

Image

Examples

Embodiment 1

[0024] Embodiment 1: Install the four-necked flask with electric stirrer, dropping funnel, thermometer, condensation dehydrator, drop into 50.0 grams of phenol (heating in advance makes phenol completely melt), add cationic resin catalyst C 102-2 (granular) 10.0 g, mix and heat up to 40--60°C, add dropwise 70.0 g of α-olefins measured under stirring, heat up to 110-120°C, and carry out the alkylation reaction for about 6 hours. After the reaction, remove the catalyst by thermal filtration (recyclable), and carry out vacuum distillation (2.0KPa, 210°C) under the protection of nitrogen to remove unreacted phenol and α-olefin to obtain alkylphenol. Molecular weight 303, hydroxyl value 4, 91%, chroma <3.5 grade, light transmittance 90%, conversion rate 75.5%.

[0025] With electric stirring, the three-necked flask of condensing dehydrator is installed, puts into the alkylphenol prepared in the alkylation reaction of 100.0 grams, 65.0 grams of lubricating oil base oils (turbine oil...

Embodiment 2

[0028] Embodiment 2: Install the four-necked flask with electric stirrer, dropping funnel, thermometer, condensation dehydrator, drop into 50.0 grams of phenol (heating in advance makes phenol completely melt), add cationic resin catalyst C 102-2 (granular) 10.0 g, mix and heat up to 40--60°C, add dropwise 62.5 g of α-olefins measured under stirring, heat up to 110-120°C, and carry out the alkylation reaction for about 6 hours. After the reaction is over, remove the catalyst by thermal filtration (recyclable), and carry out vacuum distillation (2.0KPa, 210°C) under the protection of nitrogen to remove unreacted phenol and α-olefin to obtain alkylphenol. Molecular weight 306, hydroxyl value 4, 95%, chroma <3.5 grade, light transmittance 81%, conversion rate 86.2%.

[0029] Install the three-necked flask with electric stirring and condensation dehydrator, put into 100.0 grams of alkylphenol prepared in the alkylation reaction, 65.0 grams of lubricating oil base oil (turbine oil,...

Embodiment 3

[0032] Embodiment 3: the four-neck flask with electric stirrer, dropping funnel, thermometer, condensation dehydrator is installed, drop into 50.0 grams of phenol (heating in advance makes phenol completely melt), add cationic resin catalyst C 102-2 (granular) 8.0 g, mix and heat up to 40--60°C, add 62.5 g of measured α-olefin dropwise under stirring, heat up to 110-120°C, and carry out the alkylation reaction for about 6 hours. After the reaction is over, remove the catalyst by thermal filtration (recyclable), and carry out vacuum distillation (2.0KPa, 210°C) under the protection of nitrogen to remove unreacted phenol and α-olefin to obtain alkylphenol. The molecular weight is 292, the hydroxyl value is 5.08%, the chromaticity is less than 3.5, the light transmittance is 82%, and the conversion rate is 75.1%.

[0033] Install the three-necked flask with electric stirring and condensation dehydrator, put into 100.0 grams of alkylphenol prepared in the alkylation reaction, 65.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com