Method for producing margin coal gas by using steel in rotary cement kiln predecomposition furnace

A cement rotary kiln and precalciner technology, applied in cement production, rotary drum furnace, clinker production, etc., to reduce environmental pollution, reduce gas emissions, and improve energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

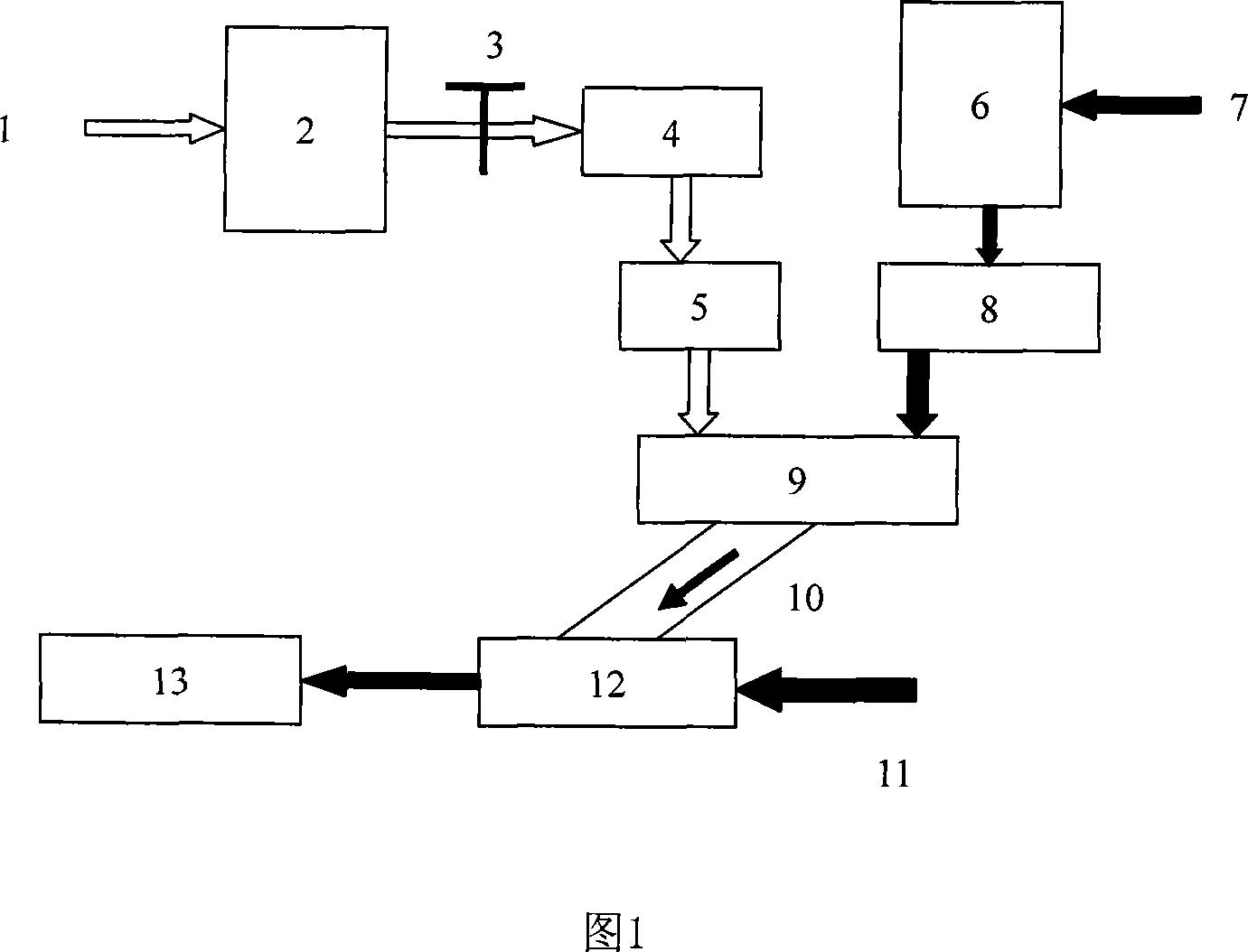

[0018] A method for utilizing surplus coal gas from steel production in a cement rotary kiln precalciner. The process flow is shown in Figure 1. It includes the gas stabilization and transportation process, and the combustion and heating process of the gas in the calciner. Its characteristics are: It mainly includes the following steps:

[0019] A. The coal gas with large pressure fluctuations in the steel production process is transported to the gas stabilizer tank through the gas pipeline. After the gas is stabilized by the stabilizer tank, the gas is sent into the burner by adjusting the gas flow control valve, and the gas is burned After the device is sprayed into the pre-combustion chamber for pre-combustion, it enters the combustion chamber and forms a high-temperature flame in the combustion chamber to pre-decompose the cement raw meal;

[0020] B. Cement raw meal enters the tertiary air pipe through the four-stage discharge pipe, and is blown into the combustion chamber co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com