Method for grading and conditioning coal by stable obtained coke oven smoke

A technology of coke oven flue and coke oven, which is applied in coke oven and petroleum industry to achieve the effect of reducing moisture and stabilizing suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

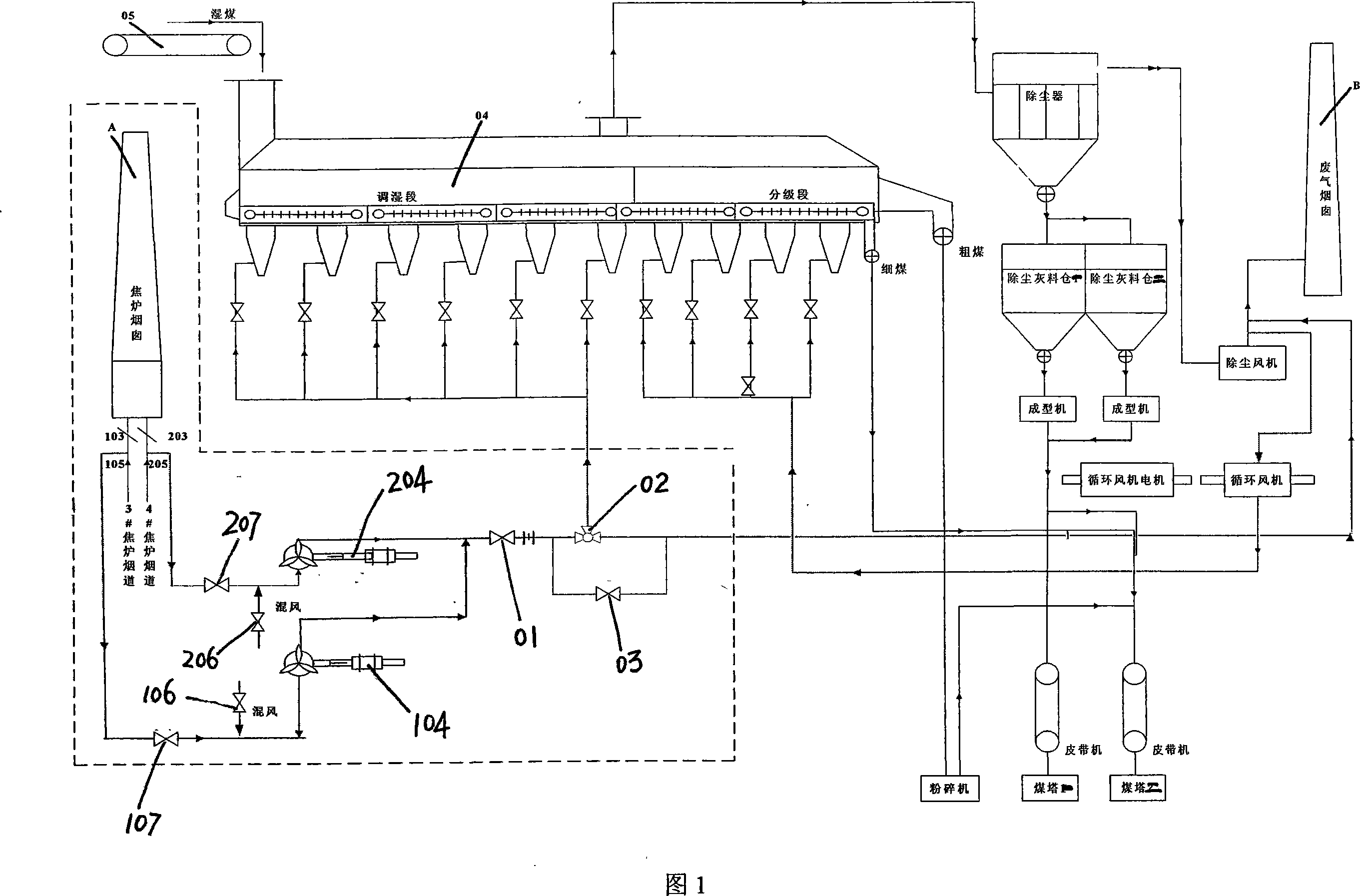

[0018] The mixed coal is transported to the upper part of the fluidized bed 04 through the belt conveyor 05.

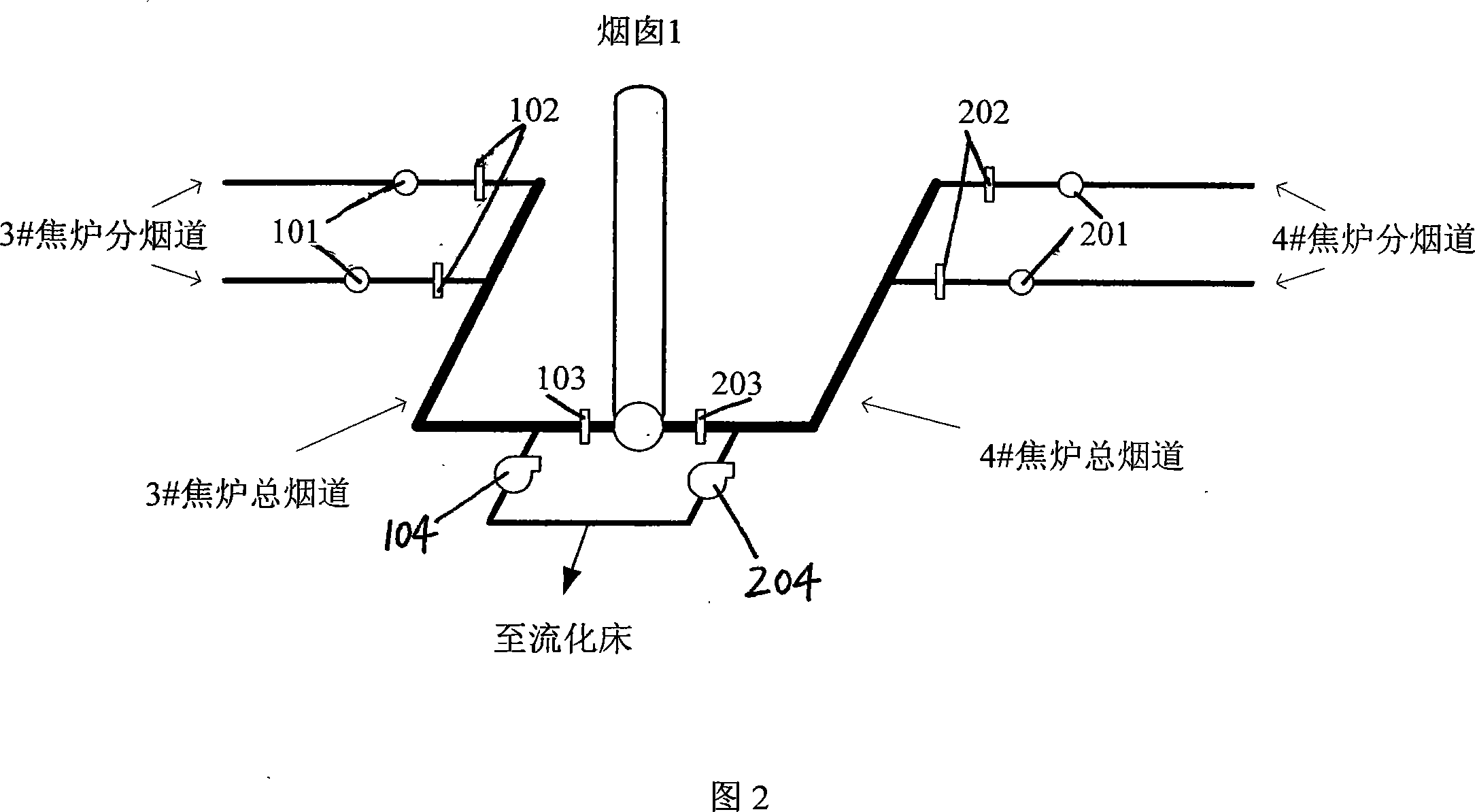

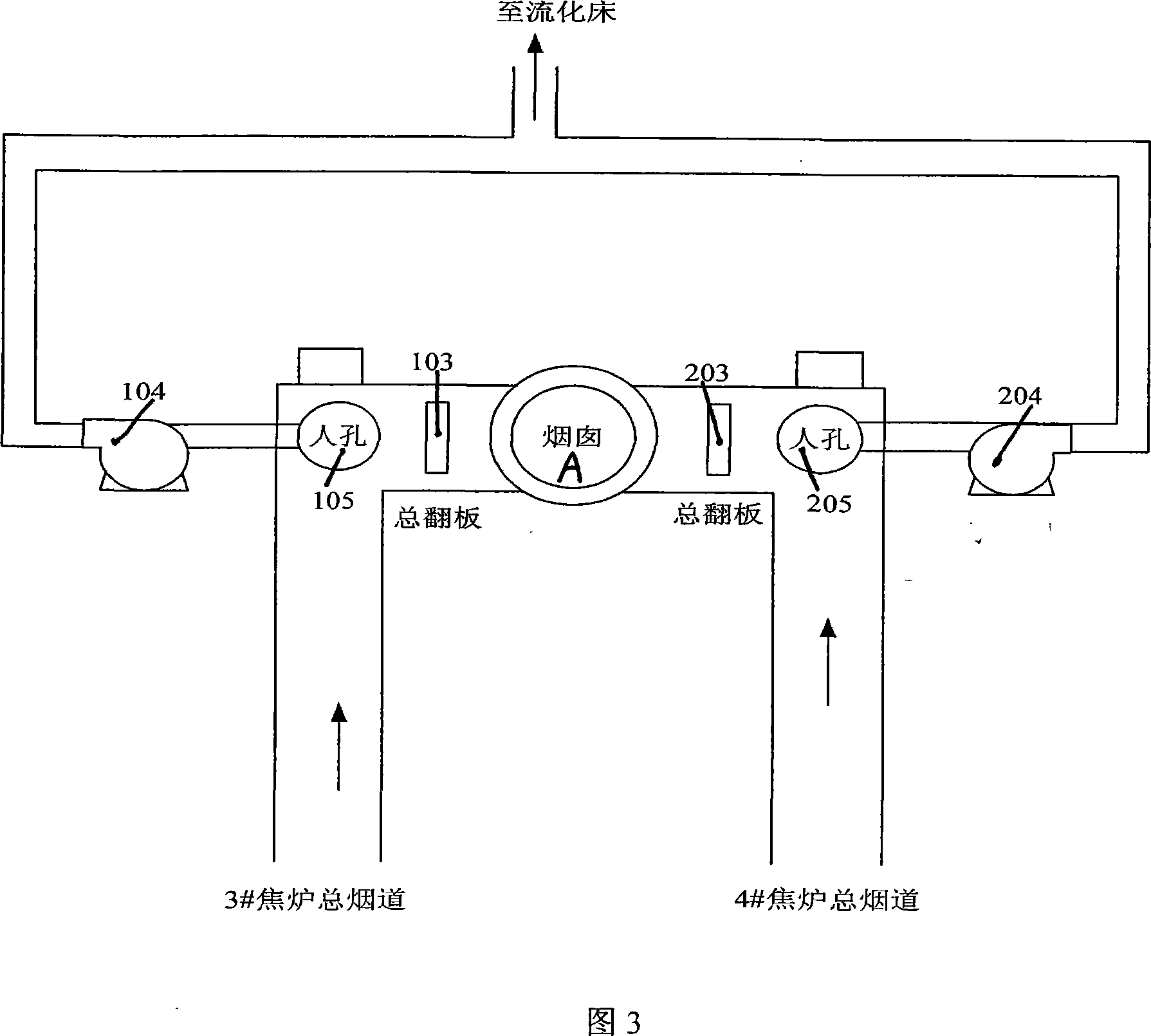

[0019] The coke oven flue exhaust gas (temperature about 230°C) is drawn from the 3# and 4# coke oven sub-flue through the manhole through the exhaust gas induced draft fan 104 and 204, and then passes through the flow regulating valve 01 and the pneumatic three-way switching valve 02. The road drum enters the lower part of both sides of the fluidized bed 04, and the two sides are divided into 6 branch pipes to enter the fluidized bed, pass through the sieve plate, and fully contact the raw coal to evaporate the water in the coal to achieve the purpose of humidity control. This process requires the flue suction of each coke oven to be stable, and the pressure behind the fan is stable, so as to ensure that the gas pressure entering the fluidized bed is stable.

[0020] The exhaust gas at the top of the fluidized bed is drawn into the bag filter by the dust removal fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com