Plasticizing enhancement nylon 6 composite material with good apparent mass and preparation method thereof

A technology of appearance quality and composite materials, applied in the field of toughened and reinforced nylon 6 composite materials and its preparation, can solve the problems of loss of mechanical properties and thermal properties of materials, achieve changes in flow characteristics, solve parts warping, appearance good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

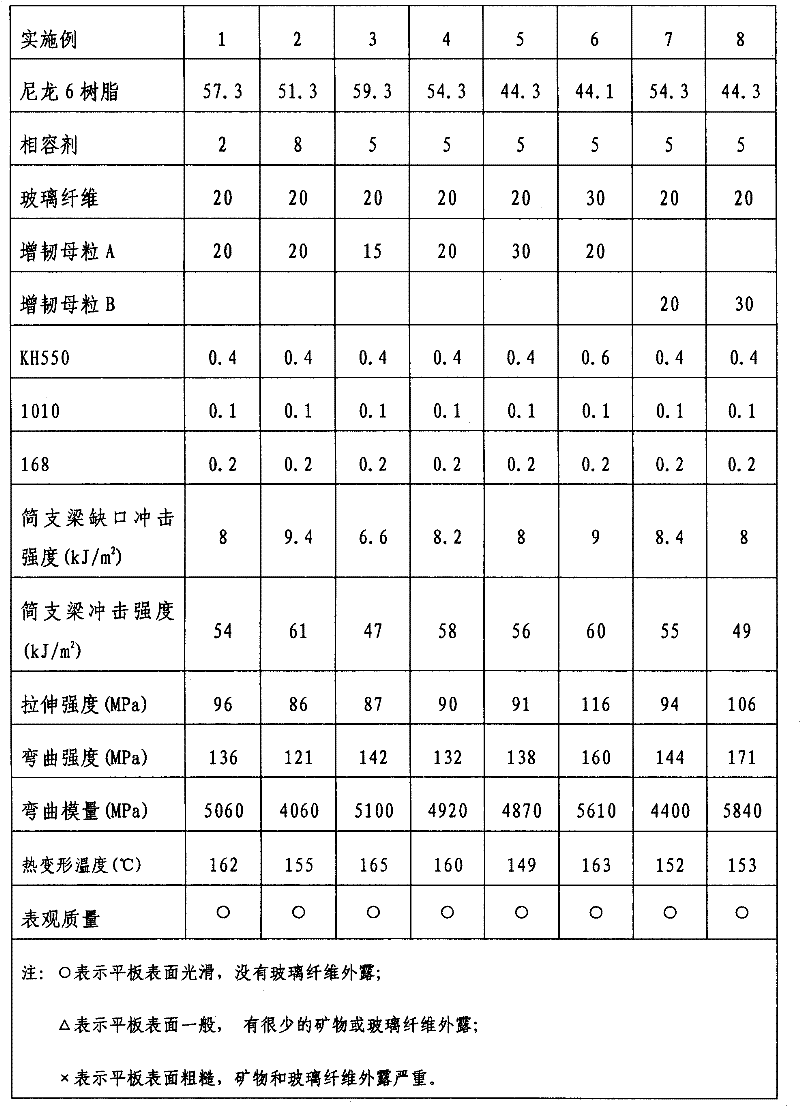

[0042] The weight ratio of PA6 resin is 57.3%, the weight ratio of MAPP is 2%, the weight ratio of toughened masterbatch A is 20%, the weight ratio of KH550 is 0.4%, and the weight ratio of 1010 / 168 is 0.1 / 0.2%. The above components are mixed at room temperature (the glass fiber with a weight ratio of 20% is added from the first exhaust port), and the TE-35 (L / D=48) twin-screw extruder produced by Nanjing Keya Company is used to produce , the processing temperatures (from the feed port to the die) are: 170 ° C, 200 ° C, 215 ° C, 220 ° C, 230 ° C, the host speed is 30 Hz, the test results are listed in Table 1.

Embodiment 2

[0044] The weight ratio of PA6 resin is 51.3%, the weight ratio of MAPP is 8%, the weight ratio of toughened masterbatch A is 20%, the weight ratio of KH550 is 0.4%, and the weight ratio of 1010 / 168 is 0.1 / 0.2%. The above components are mixed at room temperature (the glass fiber with a weight ratio of 20% is added from the first exhaust port), and the TE-35 (L / D=48) twin-screw extruder produced by Nanjing Keya Company is used to produce , the processing temperatures (from the feed port to the die) are: 170 ° C, 200 ° C, 215 ° C, 220 ° C, 230 ° C, the host speed is 30 Hz, the test results are listed in Table 1.

Embodiment 3

[0046] The weight ratio of PA6 resin is 59.3%, the weight ratio of MAPP is 5%, the weight ratio of toughened masterbatch A is 15%, the weight ratio of KH550 is 0.4%, and the weight ratio of 1010 / 168 is 0.1 / 0.2%. The above components are mixed at room temperature (the glass fiber with a weight ratio of 20% is added from the first exhaust port), and the TE-35 (L / D=48) twin-screw extruder produced by Nanjing Keya Company is used to produce , the processing temperatures (from the feed port to the die) are: 170 ° C, 200 ° C, 215 ° C, 220 ° C, 230 ° C, the host speed is 30 Hz, the test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com