Nano metal particle and its nano carbon tube and its luminous element preparation method

A technology of nano-metal particles and nano-carbon tubes, which is applied in nano-structure manufacturing, discharge tube/lamp manufacturing, nano-technology, etc., and can solve problems such as high production cost, no industrial application value, and complicated transfer printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

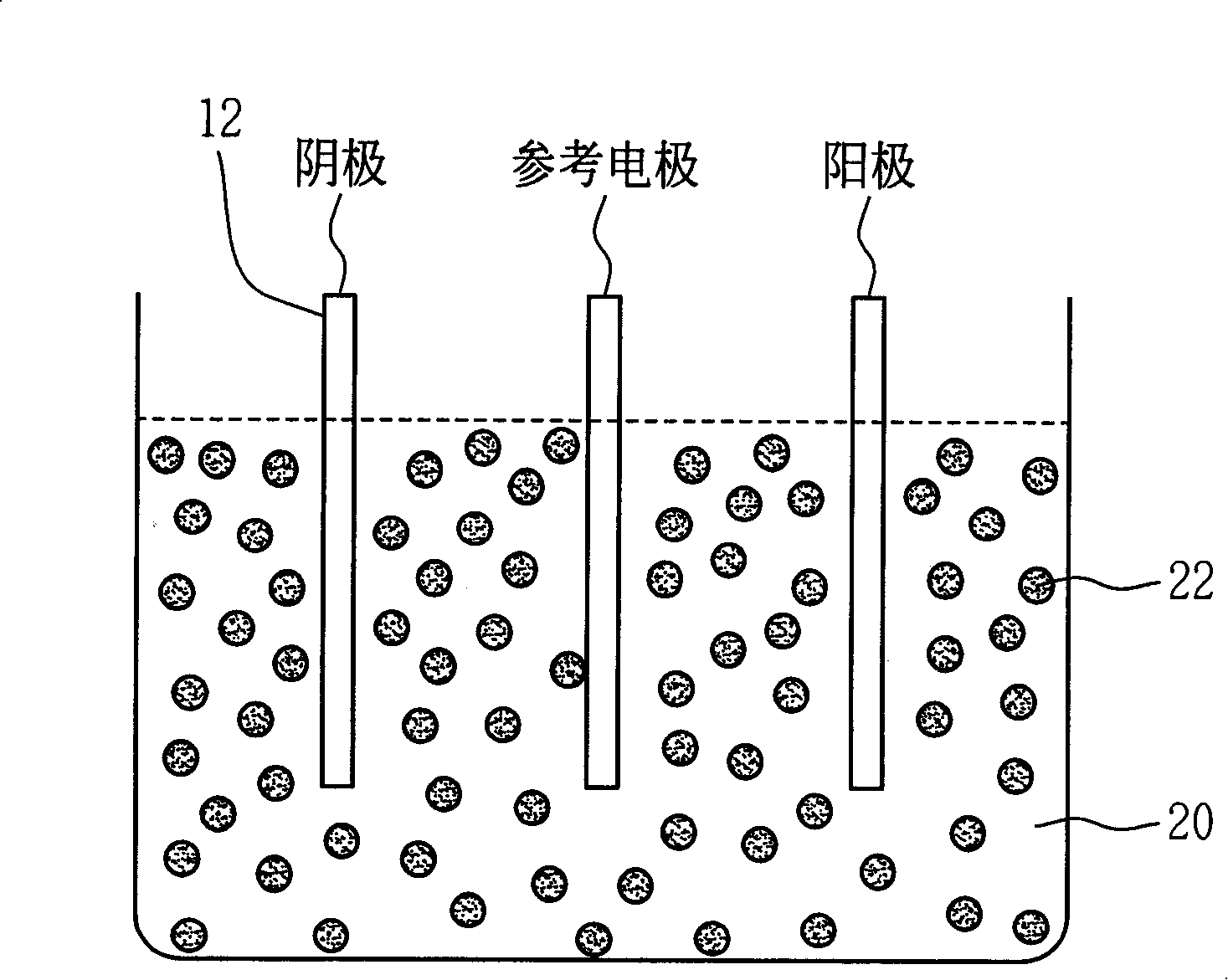

[0022] FIG. 1( a ) and FIG. 1( b ) illustrate the preparation method of the nano metal particles 16 of the present invention. In the preparation method of the present invention, a conductive substrate 12 is soaked in an electroplating solution 20 containing metal ions 22, and then an electroplating process (such as a cyclic potential electroplating process) is performed to reduce the metal ions 22 to form nano-metal particles 16 in the electroplating solution 20. on the conductive substrate 12 . Preferably, the size of the nano metal particles 16 is between 1 nm and 150 nm. The conductive substrate 12 may include indium tin oxide (ITO) with a lattice size ranging from 5 nm to 500 nm, the electroplating solution 20 may include nickel nitrate, nickel sulfate, or nickel chloride, and the nano-metal particles 16 It may be nickel metal particles. In addition, the electroplating solution 20 can also be magnetic metal ions such as iron ions or cobalt ions, and the nano-metal partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com