Inorganic/organic nano composite antibacterial agent and its fabric product application

A technology of inorganic antibacterial agent and organic antibacterial agent, which is applied in the field of inorganic/organic nanocomposite antibacterial agent, can solve the problems of poor antibacterial performance of antibacterial fiber fabric, weaken the antibacterial effect of antibacterial agent, etc., and achieve excellent comprehensive performance, good appearance, and processability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

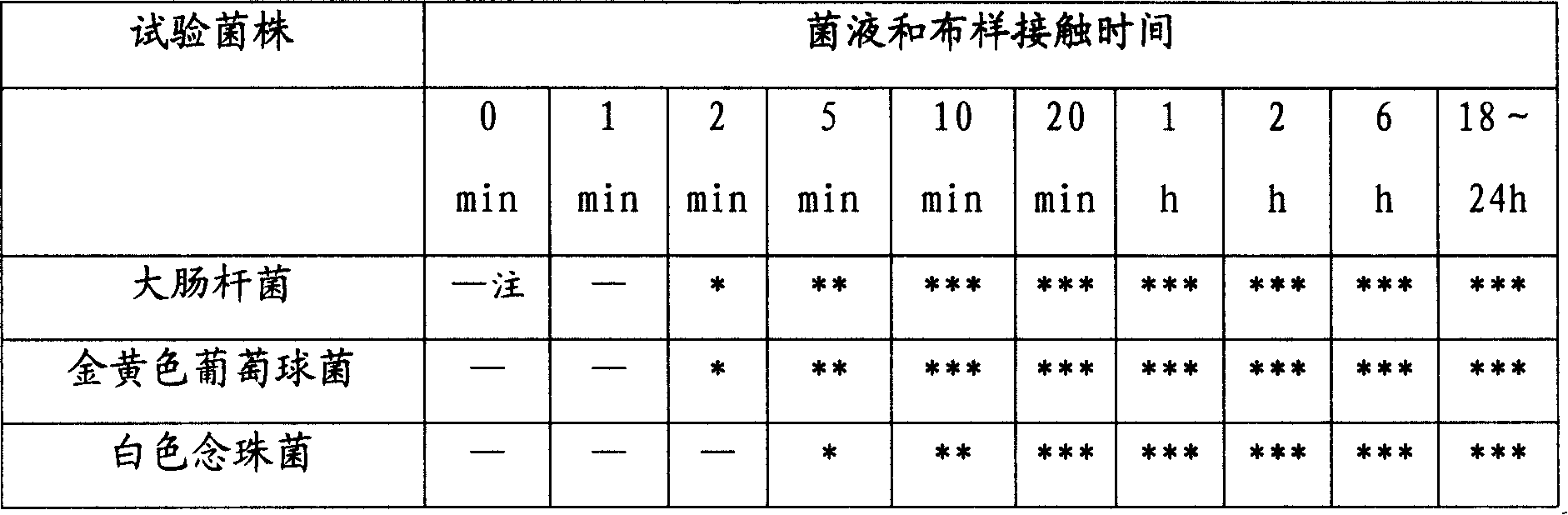

Embodiment 1

[0037] Embodiment 1 The zirconium phosphate type inorganic antimicrobial agent that the weight 6g silver content is 3.5%, primary particle diameter average value is 35nm, aggregate apparent average particle diameter is 1.6 μ m, moves into the 150ml of the lining polyurethane resin of sand mill Stainless steel body barrel. 100g of zirconia beads of Φ0.5mm are placed in the barrel in advance. After adding 0.003g of sodium thiosulfate, add 100ml of distilled water and grind at 2000rpm for 5min. Add 0.05g of N-aminoethylaminopropyltrimethylsilane, increase the rotational speed to 3000rpm, and grind for 5min. Add 10g of 1,1'-hexamethylenebis[5-(4-chlorophenyl)biguanide] digluconate, and grind at 3000rpm for 5min. The zirconia beads were separated using a 325 mesh sieve. Then, add 0.5g TWEEN-80 to the sieved mixed liquid, and disperse at 4000rpm for 5min. Add 10 g of polyacrylate emulsion HB959 (Beijing Huyi Chemical Factory), and stir at 100 rpm for 10 min to become a milky whi...

Embodiment 2

[0038] Embodiment 2 The silica gel type inorganic antibacterial agent that the weight 6g silver content is 3.0%, zinc content is 8.0%, average particle diameter is 1.2 μ m, maximum particle diameter is less than 5 μ m, moves into the 150ml of the liner polyurethane resin of sand mill Stainless steel body barrel. 100g of zirconia beads of Φ0.5mm are placed in the barrel in advance. After adding 0.003g of sodium thiosulfate, add 100ml of distilled water and grind at 2000rpm for 5min. Add 0.05g of N-aminoethylaminopropyltrimethylsilane, increase the rotational speed to 3000rpm, and grind for 5min. Add 10g of 1,1'-hexamethylenebis[5-(4-chlorophenyl)biguanide] digluconate, and grind at 3000rpm for 5min. The zirconia beads were separated using a 325 mesh sieve. Then, 0.5 g of TWEEN-80 was added to the ground mixed liquid, and dispersed at 4000 rpm for 5 min. Add 10 g of polyacrylate emulsion HB959 (Beijing Huyi Chemical Factory), and stir at 100 rpm for 10 min to form a milky wh...

Embodiment 3

[0039] Example 3 The soluble glass-type inorganic antibacterial agent with a silver content of 3.1%, an average particle size of 3 μm, and a maximum particle size of less than 10 μm with a weight of 6 g was moved into a 150 ml stainless steel inner barrel of a sand mill lined with polyurethane resin. 100g of zirconia beads of Φ1mm are placed in the barrel in advance. After adding 0.003g of sodium thiosulfate, add 100ml of distilled water and grind at 2000rpm for 5min. Add 0.05g of N-aminoethylaminopropyltrimethylsilane, increase the rotational speed to 3000rpm, and grind for 5min. Add 10g of 1,1'-hexamethylenebis[5-(4-chlorophenyl)biguanide] digluconate, and grind at 3000rpm for 5min. The zirconia beads were separated using a 325 mesh sieve. Then, 0.5 g of TWEEN-80 was added to the ground mixed liquid, and dispersed at 4000 rpm for 5 min. Add 10 g of polyacrylate emulsion HB959 (Beijing Huyi Chemical Factory), and stir at 100 rpm for 10 min to form a milky white suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com