AC power system voltage sensor

A voltage sensor, power system technology, applied in the direction of measuring current/voltage, voltage divider, instruments, etc., can solve the problems of unstable voltage divider ratio, large electromagnetic interference, heavy weight, etc., to achieve good linearity and accuracy, good Safety features, effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

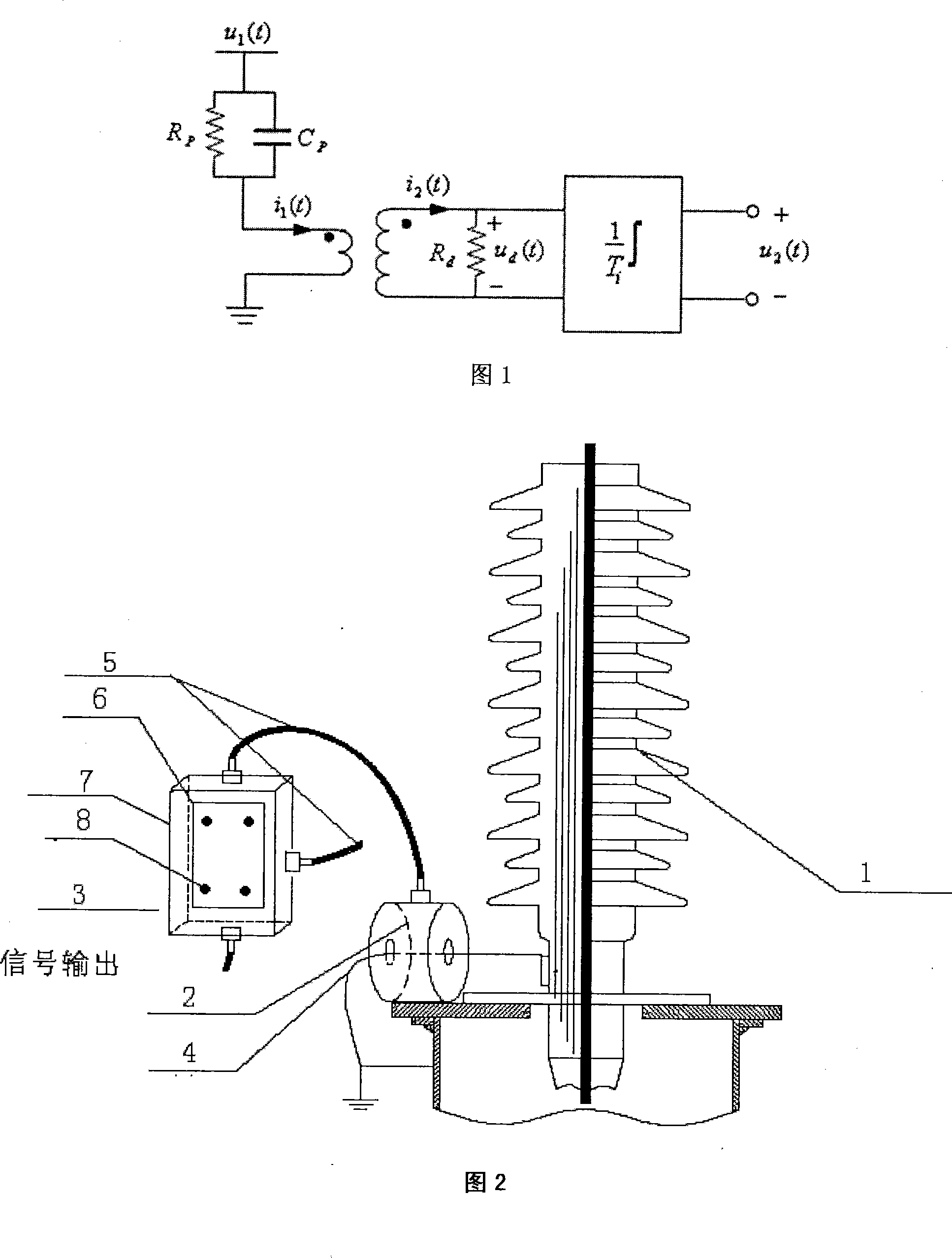

[0032]As shown in Figures 1 to 3: a 110kV AC power system voltage sensor, including a 110kV transformer capacitor bushing 1, a current coil 2, an electronic conversion unit 3, a grounding wire 4 at the end of the bushing, a coaxial cable 5, and a grounding wire 4 One end is connected to the end screen of the transformer capacitor bushing 1, and the other end is grounded through the current coil 2. The current coil 2 and the electronic conversion unit 3 are connected through a coaxial cable 5, and the output of the electronic conversion unit 3 is output to the second coil through the coaxial cable. Three-party acquisition device. The current coil 2 is composed of a nanocrystalline alloy annular iron core, a winding, a double-layer shielding structure, a shielding shell and a coaxial cable connector. In the shielding shell, the windings are respectively set from the inside to the outside. The number of turns wound by enameled wire with a diameter of 0.19mm It is a 200-turn windi...

Embodiment 2

[0034] As shown in Figures 1 to 3: a 110kV AC power system voltage sensor, including 110kV capacitive current transformer 1, current coil 2, electronic conversion unit 3, bushing end screen grounding wire 4, coaxial cable 5, grounding wire 4. One end is connected to the end screen of the capacitive current transformer 1, and the other end is grounded through the current coil 2. The current coil 2 and the electronic conversion unit 3 are connected through a coaxial cable 5, and the output of the electronic conversion unit 3 is output through a coaxial cable. to a third-party collection device. The current coil 2 is composed of a nanocrystalline alloy annular iron core, a winding, a double-layer shielding structure, a shielding shell and a coaxial cable connector. In the shielding shell, the windings are respectively set from the inside to the outside. The number of turns wound by enameled wire with a diameter of 0.15mm It is a winding of 500 turns, a nanocrystalline alloy annul...

Embodiment 3

[0036]As shown in Figures 1 to 3: a 110kV AC power system voltage sensor, including 110kV capacitive voltage transformer 1, current coil 2, electronic conversion unit 3, bushing end screen grounding wire 4, coaxial cable 5, grounding wire 4. The end screen of the potential transformer 1 at one end and the other end pass through the current coil 2 to ground, and the current coil 2 and the electronic conversion unit 3 are connected through a coaxial cable 5, and the output of the electronic conversion unit 3 is output to a third party through a coaxial cable collection device. The current coil 2 is composed of a nanocrystalline alloy annular iron core, a winding, a double-layer shielding structure, a shielding shell and a coaxial cable connector. In the shielding shell, the windings are respectively set from the inside to the outside. The number of turns wound by enameled wire with a diameter of 0.15mm It is a 600-turn winding, a nanocrystalline alloy annular iron core and a dou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com