Inverter-integrated electric compressor

A technology of electric compressors and inverters, which is applied in the direction of machines/engines, liquid variable capacity machines, motors, etc., can solve problems such as inability to cool uniformly, unbalanced, unstable movements, etc., to ensure cooling performance and Effects of light weight and assemblability, increased rigidity, and stable motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

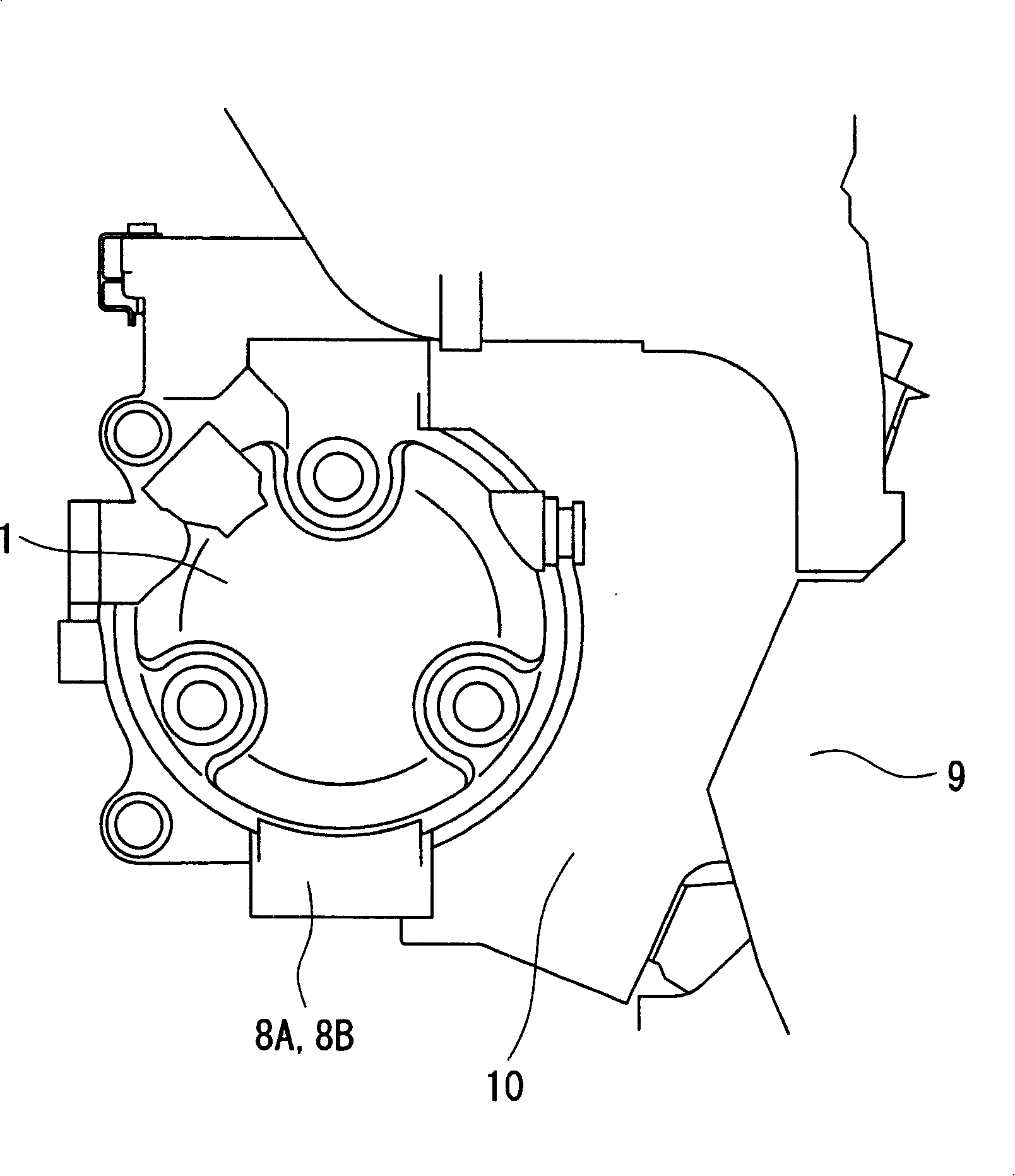

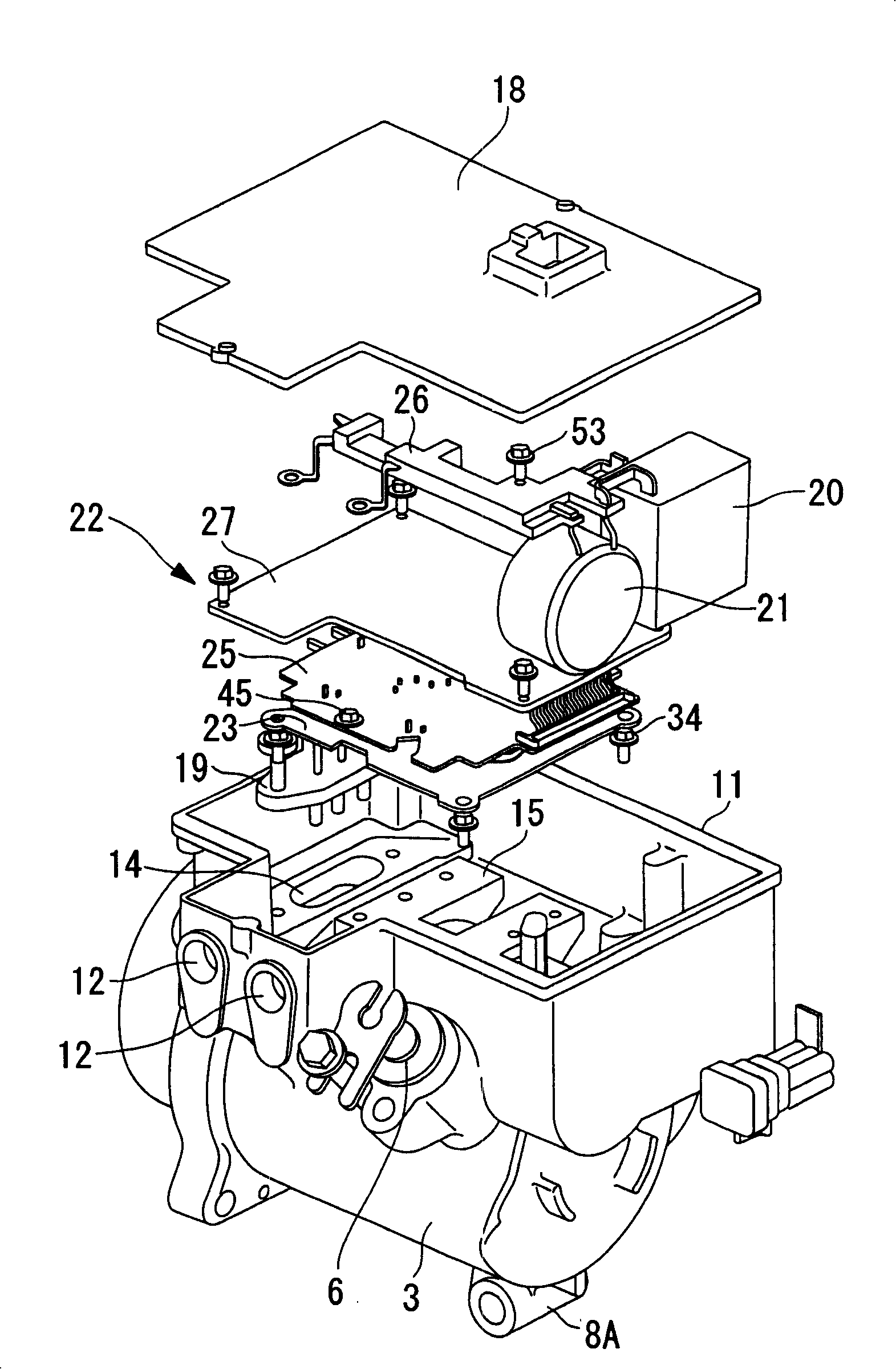

[0064] Hereinafter, an embodiment of the present invention will be described with reference to FIGS. 1 to 9 .

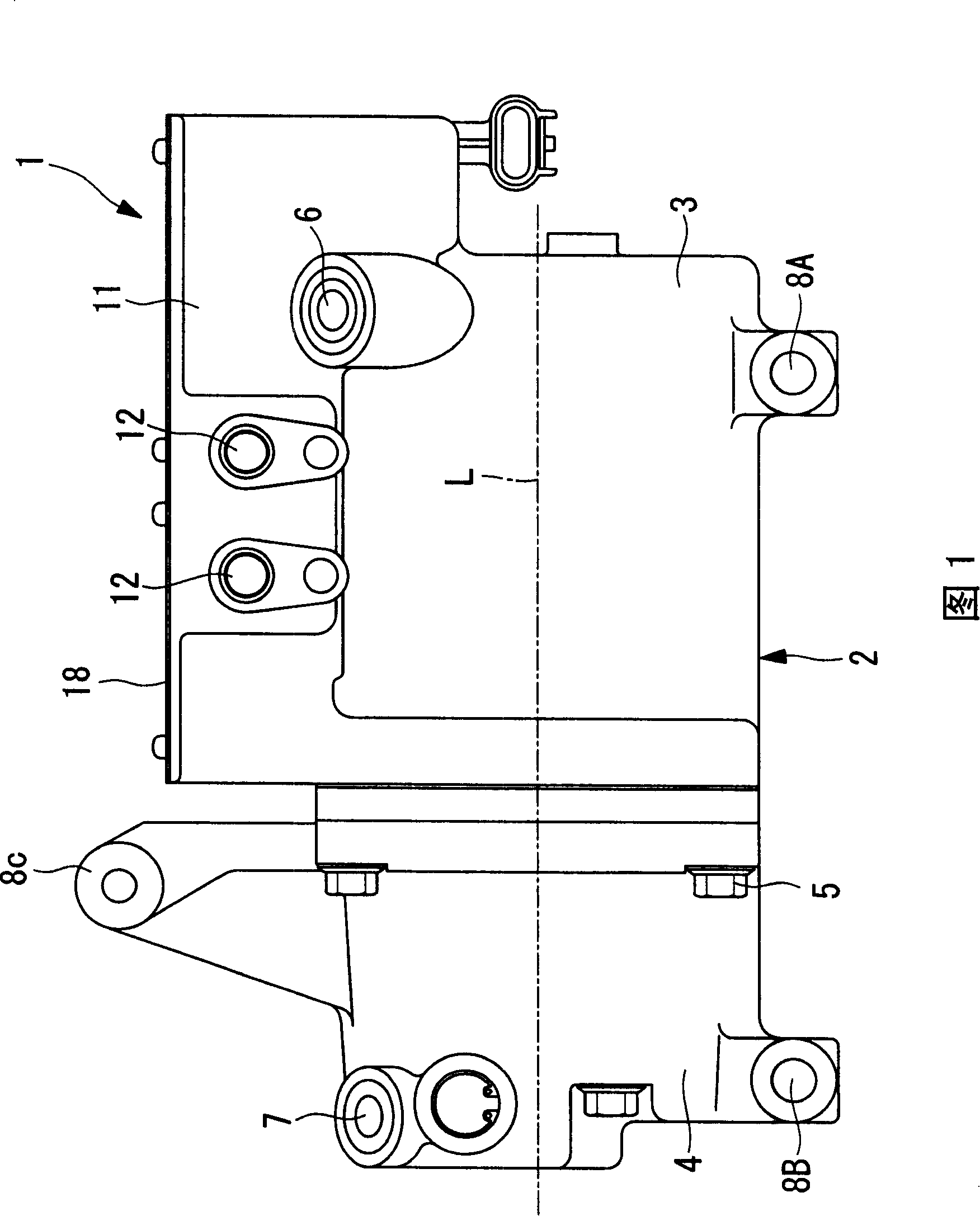

[0065] FIG. 1 shows an external appearance side view of an inverter-integrated electric compressor 1 according to an embodiment of the present invention. The inverter-integrated electric compressor 1 has a casing 2 constituting its casing. The housing 2 is formed by integrally fastening a motor housing 3 accommodating an electric motor (not shown) and a compressor housing 4 accommodating a compressor (not shown) tightly by bolts 5 . The motor casing 3 and the compressor casing 4 are made by die casting.

[0066] An electric motor and a compressor (not shown) accommodated in the motor housing 3 and the compressor housing 4 are connected via a motor shaft, and the compressor is driven by rotation of the electric motor. At the rear end of the motor housing 3 (the right side in FIG. 1 ), a suction port 6 is provided. The low-pressure refrigerant gas sucked into the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com