Precise forming technique for continuous glass fibre

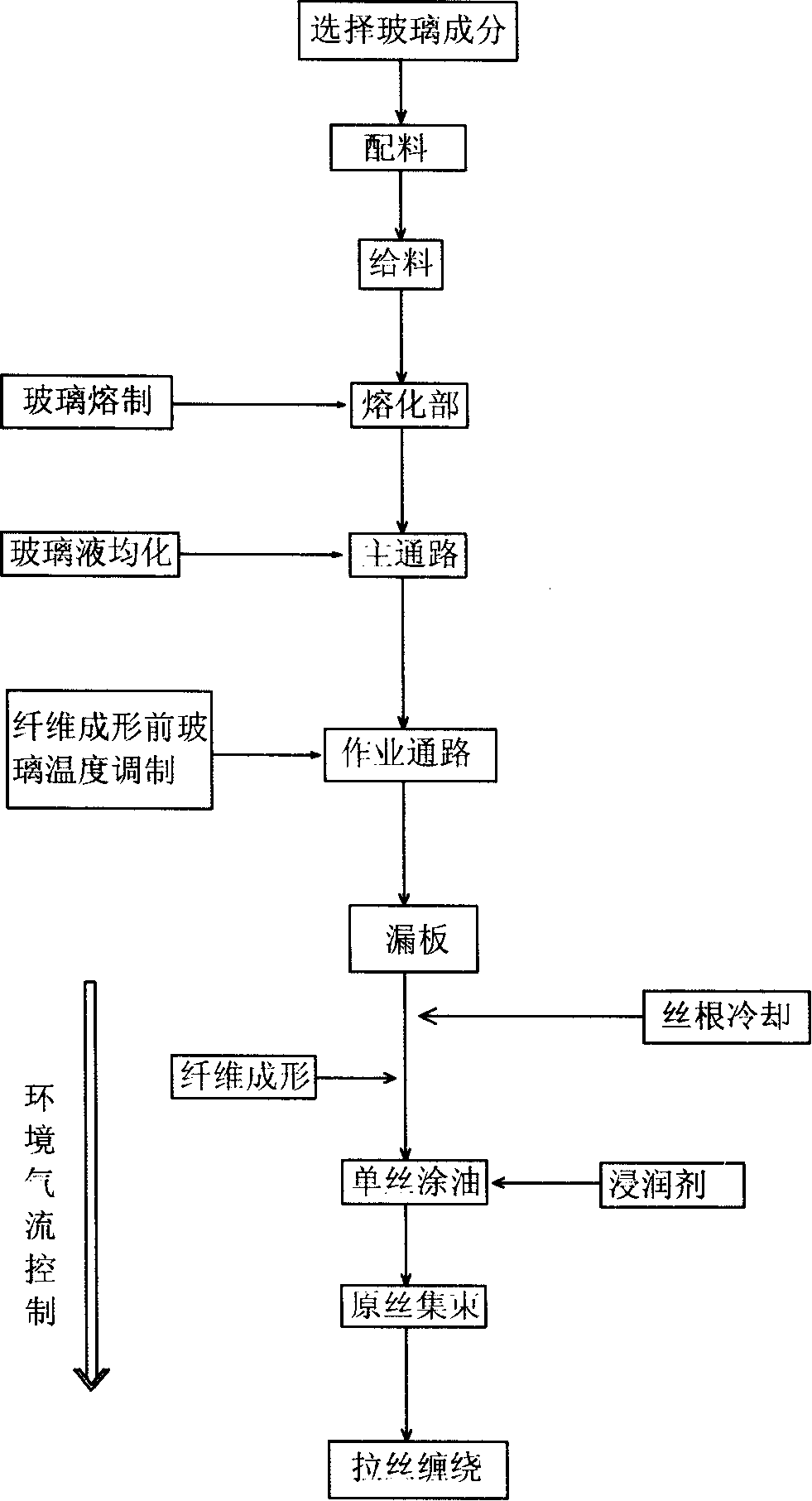

A forming process and glass fiber technology, applied in glass production, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of wire drawing breakage, uneven diameter and linear density of flying wire and monofilament, and insufficient control, and reduce the End-breaking, continuous glass forming for precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention provides a preferred embodiment for the precise formation of continuous glass fibers. Among them, the selected glass composition includes silicon dioxide (SiO 2 ), aluminum oxide (Al 2 o 3 ), boron trioxide (B 2 o 3 ), Calcium Oxide (CaO), Magnesium Oxide (MgO), Basic Oxide R 2 O(Na 2 O and K 2 O), ferric oxide (Fe 2 o 3 ), titanium dioxide (TiO 2 ), fluorine (F). The proportion of each component is as follows: SiO 2 53.5~54%, Al 2 o 3 14.2~14.8%, B 2 o 3 6.5~6.8%, CaO22.5~23%, MgO less than 0.5%, R 2 O(Na 2 O, K 2 O)0.5~0.8, Fe 2 o 3 Less than 0.4%, TiO 2 Less than 0.5%, F 0.3-0.5%.

[0011] Dosing is carried out according to above-mentioned each glass composition, and raw material is put into melting part and melts, and the glass hot spot temperature of melting part is controlled between 1350~1450 ℃ in the present invention, wherein, for shallow pool (melting part pool depth 600mm), melting part The temperature is preferably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com