Master cylinder

A technology for cylinder bores and housings, applied in hydraulic brake transmissions, brakes, transportation and packaging, etc., which can solve the problems of poor piston assembly, reduced piston guidance, and a large number of parts, and shorten the invalid stroke , Reduce the processing procedure, the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

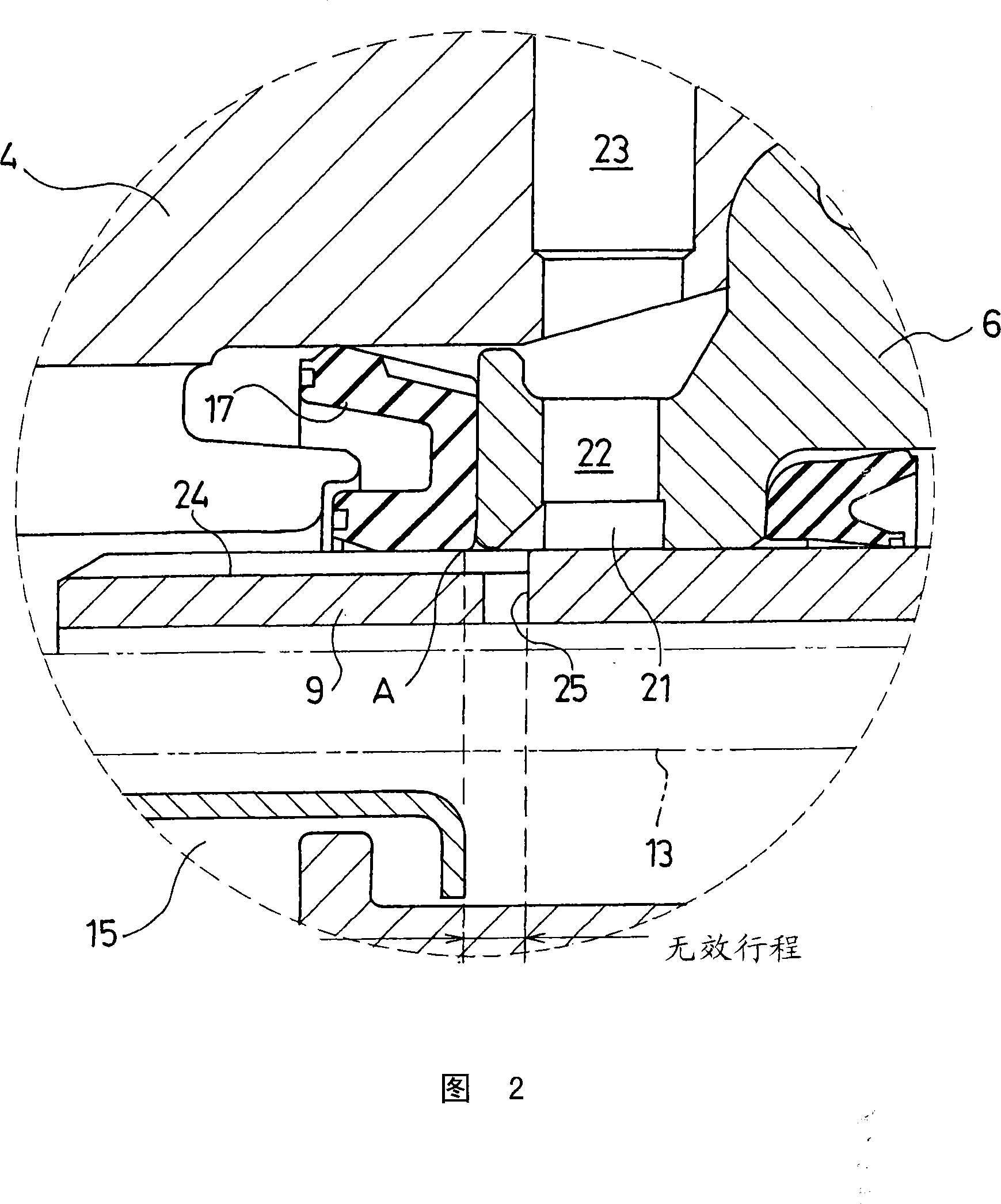

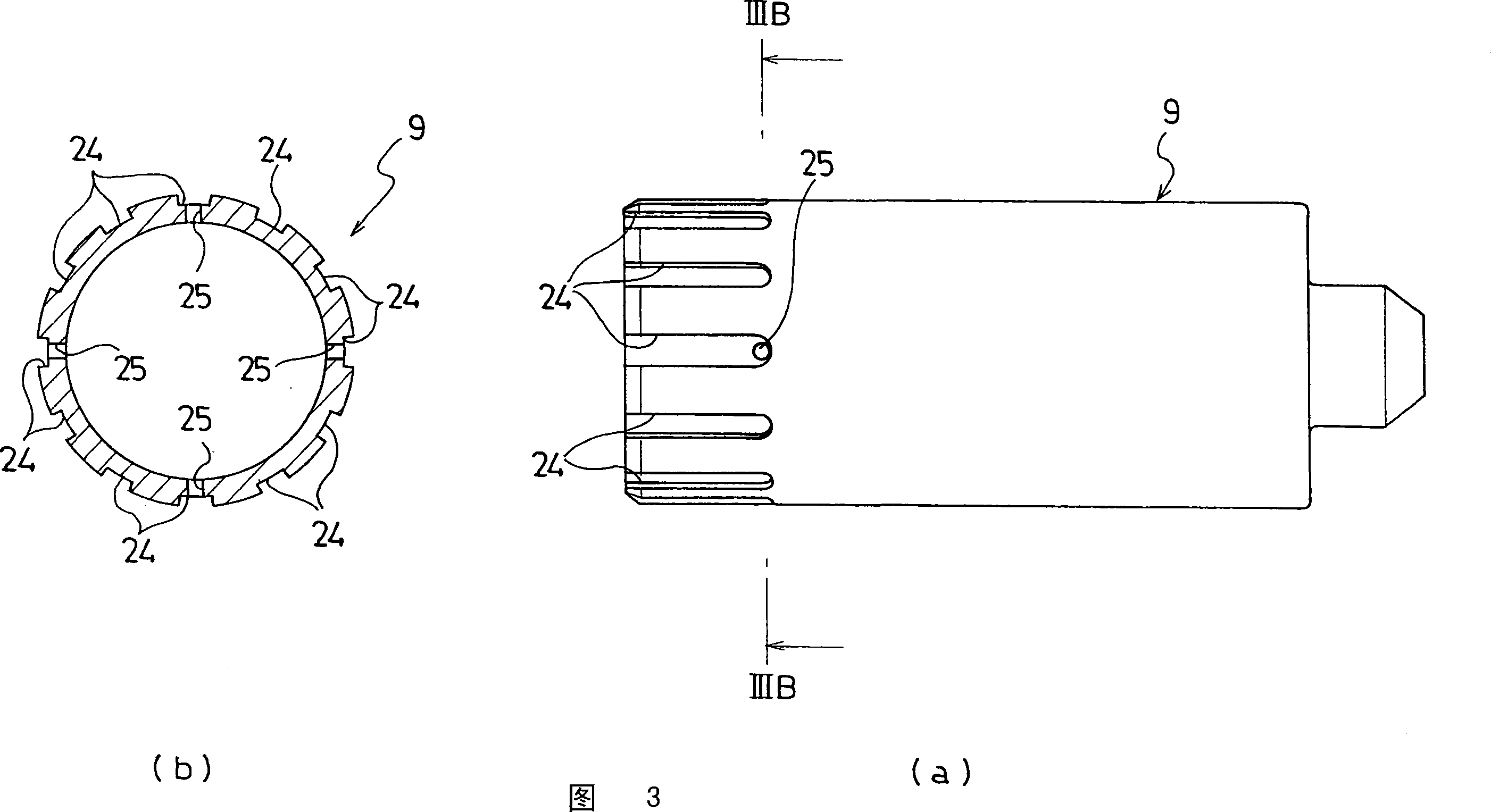

[0027] The best mode for implementing the present invention will be described below with reference to the accompanying drawings. In the following descriptions, "front" and "rear", the direction in which the piston moves when the master cylinder is working is "front", and the direction in which the piston retreats when the master cylinder is stopped is "rear", both are used in the respective descriptions "Left" and "Right" in the attached drawings.

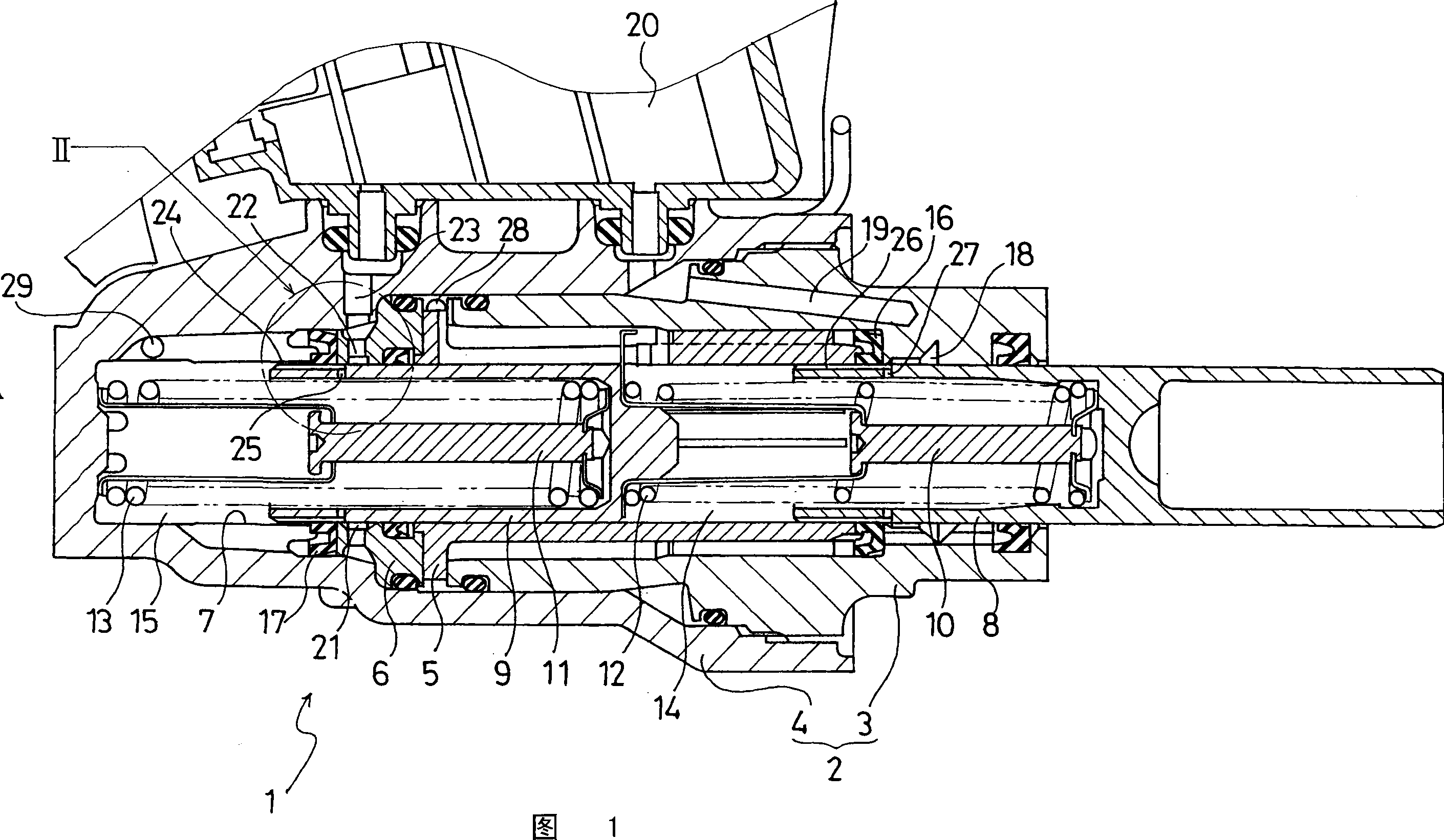

[0028] FIG. 1 is a longitudinal sectional view showing an example of an embodiment of the master cylinder of the present invention.

[0029] As shown in FIG. 1 , the master cylinder 1 of this example has a cylinder housing 2 composed of a first cylinder member 3 and a second cylinder member 4 fitted and fixed to the first cylinder member 3 . A first piston guide 5 and a second piston guide 6 are held axially between the first cylinder part 3 and the second cylinder part 4 .

[0030] A cylinder bore 7 extending in the axial direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com