Composite absorption heat pump

A two-stage absorber, one-stage technology, applied in heat pumps, energy-saving heating/cooling, lighting and heating equipment, etc., can solve the problems of not being able to fully utilize the driving heat and cooling capacity, complicating the overall system, and failing to meet heat demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

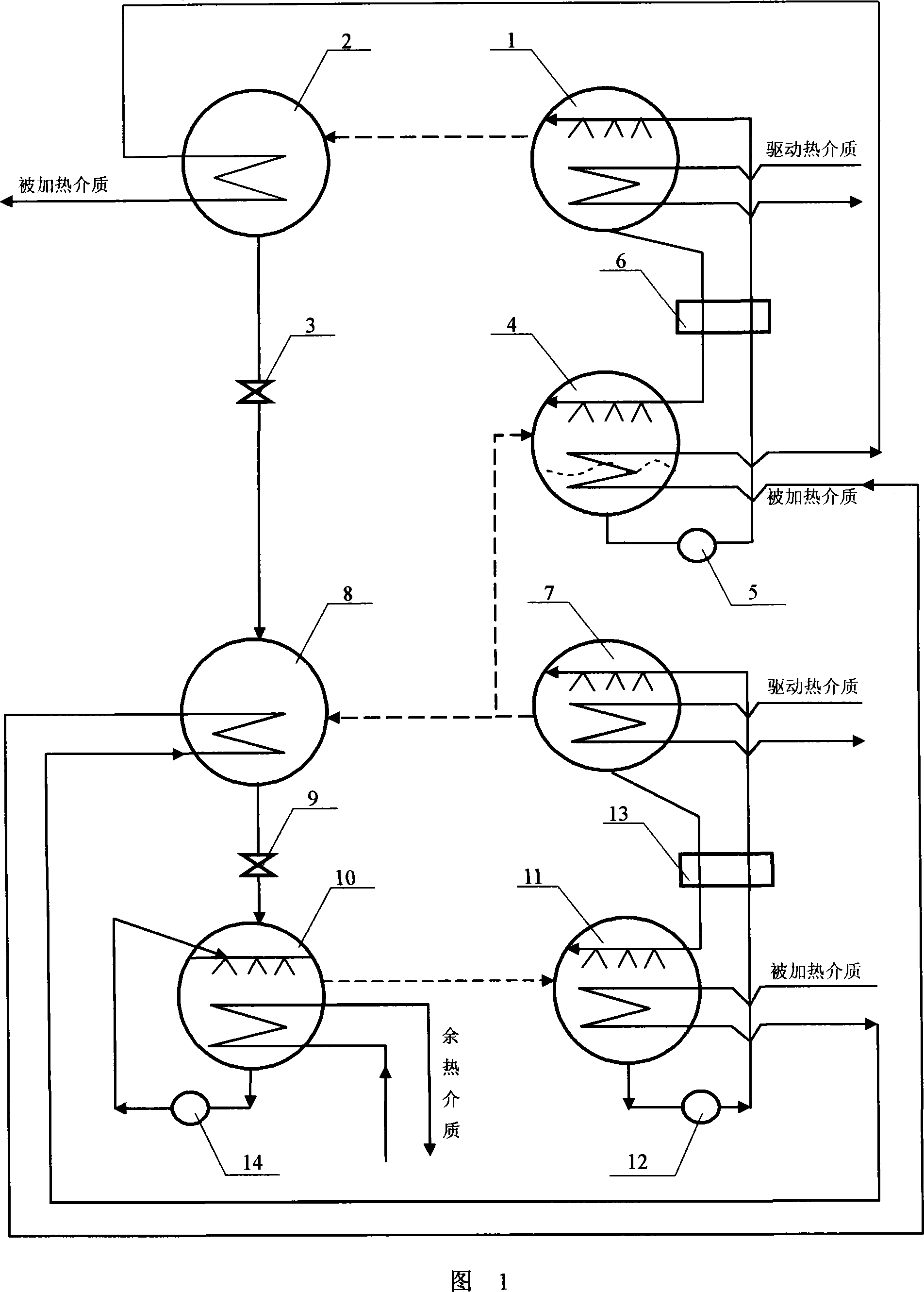

[0020] Taking the composite absorption heat pump provided according to the present invention, which can realize the functions of primary and secondary composite heat pumps, as an example, as shown in Figure 1, the purpose of the present invention is achieved in this way:

[0021] The present invention consists of secondary generator 1, secondary condenser 2, throttle valve 3, secondary absorber 4, solution pump 5, solution heat exchanger 6, primary generator 7, primary condenser 8, section Flow valve 9, evaporator 10, primary absorber 11, solution pump 12, solution heat exchanger 13 and refrigerant liquid recirculation pump 14;

[0022]Primary generator 7, primary condenser 8, throttle valve 9, evaporator 10, primary absorber 11, solution pump 12 and solution heat exchanger 13 form a primary heat pump process and structure——primary generator 7 It is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com