Method for preparing stannic oxide/silica nano composite material

A nanocomposite material, tin dioxide technology, applied in the direction of silicon dioxide, tin oxide, silicon oxide, etc., can solve the problems of reducing gas sensitivity, photocatalytic activity and other application performance, and achieve excellent thermal stability, preparation Simple method and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

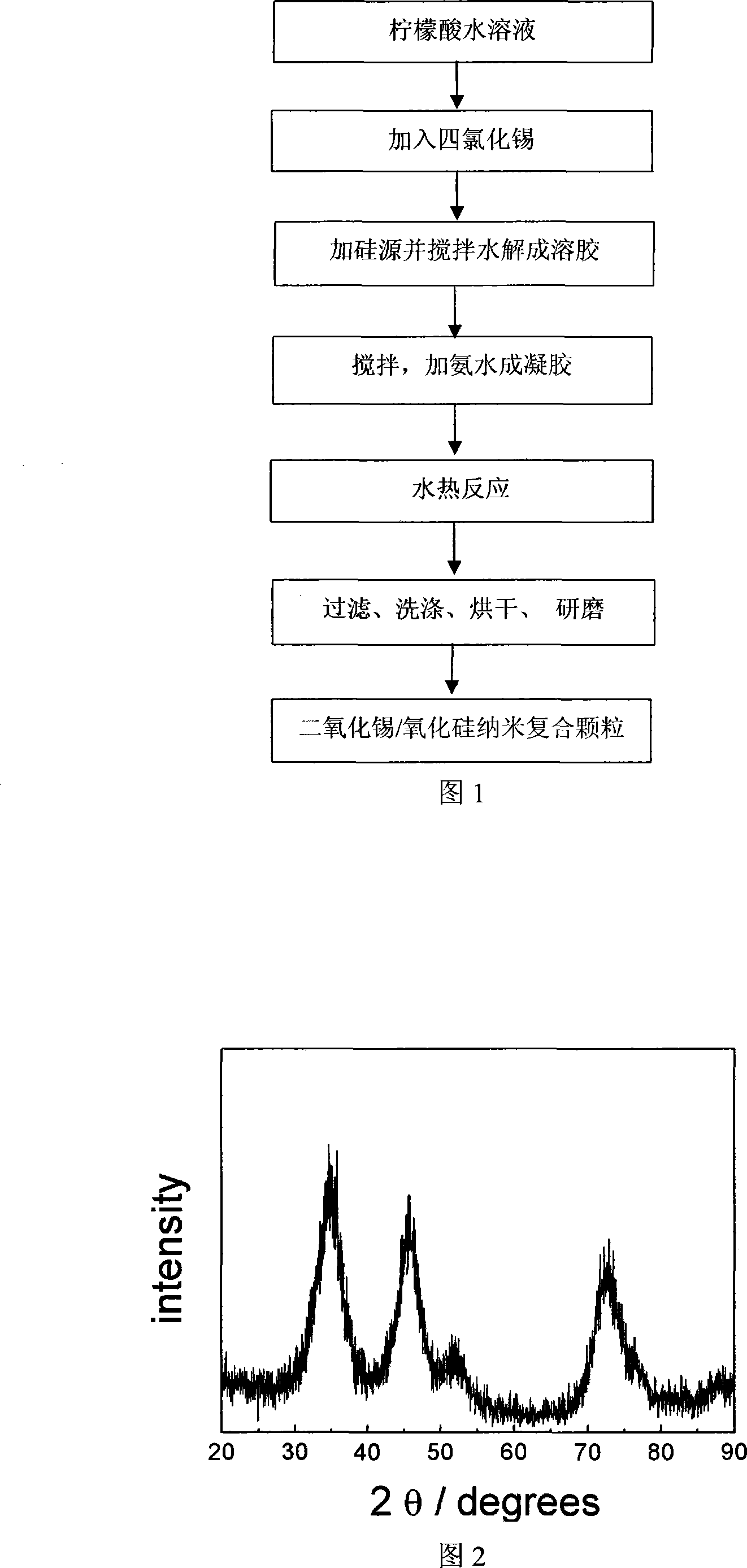

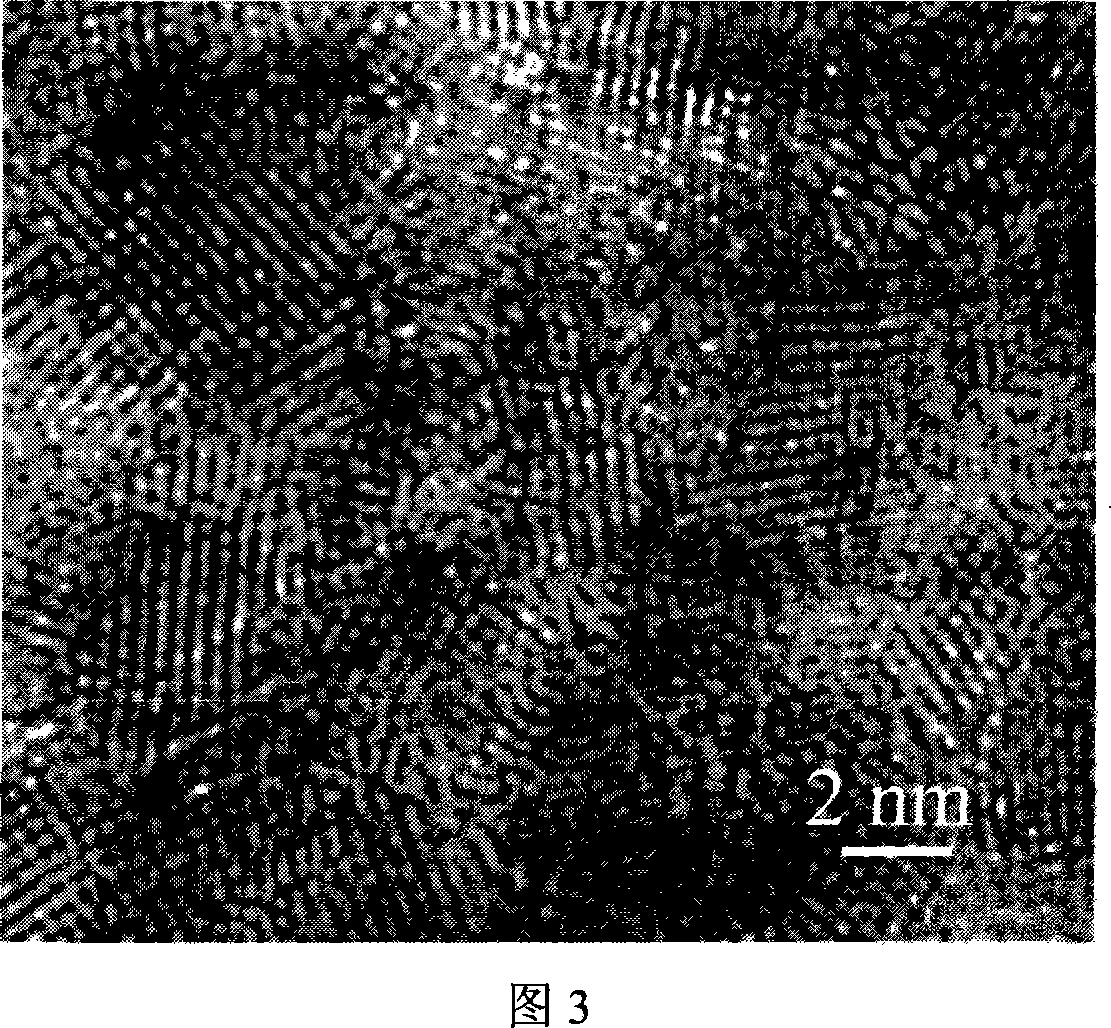

[0026] Under stirring, add citric acid to 660ml of water until the pH value of the solution is 1.5, then add 11.6g of tin tetrachloride, stir to dissolve; then heat to 50°C, add 19.8ml of ethyl orthosilicate, stir until completely hydrolyzed, A transparent sol was formed. Then, under vigorous stirring, ammonia water was slowly added until a gel was formed. Then the gel was transferred to a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction at 150°C for 10 hours. The obtained product was filtered, washed with deionized water until there was no chloride ion, dried at 110° C., and ground. That is, tin dioxide / silicon oxide nanocomposite particles with a mass ratio of silicon oxide of 10% were obtained. Observed under the electron microscope, the diameter of this kind of nanocomposite particles is 4.5 nanometers, the particles are spherical, uniform, and have good dispersion, and the specific surface area is 150.6m 2 / g. XRD measurement results show th...

Embodiment approach 2

[0028] Using the preparation process of the above-mentioned Example 1, the difference is that 59.5 ml of tetraethyl orthosilicate was added to prepare tin dioxide / silicon oxide nanocomposite particles with a silicon oxide mass ratio of 25%. Observed under the electron microscope, the diameter of this kind of nanocomposite particles is 4.0 nanometers, the particles are spherical, uniform, good dispersion, and the specific surface area is 259.0m 2 / g. XRD measurement results show that tin dioxide is rutile. The thermal stability investigation proves that it has excellent thermal stability: the sample is calcined at 400°C for 2 hours, the particle size remains at about 4.8 nanometers, and the specific surface area is 208.5m 2 / g; the sample was calcined at 800°C for 1 hour, the particle size was about 16 nanometers, and the specific surface area was 132.6m 2 / g.

Embodiment approach 3

[0030] Under stirring, add citric acid to 660ml of water until the pH of the solution is 2.0, then add 58g of tin tetrachloride, stir to dissolve; then heat to 40°C, add 89ml of tetraethyl orthosilicate, stir until completely hydrolyzed and form a transparent Sol. Then, under vigorous stirring, ammonia water was slowly added until a gel was formed. Then the gel was transferred to a polytetrafluoroethylene-lined hydrothermal kettle for hydrothermal reaction at 150°C for 10 hours. The obtained product was filtered, washed with deionized water until there was no chloride ion, dried at 105° C., and ground. That is, the silicon oxide mass ratio is 50% tin dioxide / silicon oxide nanocomposite particles. Observed under the electron microscope, the diameter of this kind of nanocomposite particles is 3.8nm, the particles are spherical, uniform, and have good dispersion, and the specific surface area is 278.9m 2 / g. XRD measurement results show that tin dioxide is rutile. The therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com