Inlet seriously distorted lower asymmetric unsteady generator

An asymmetric and generator technology, applied to aircraft parts, aircraft power units, aircraft power unit components, etc., can solve the problem of reducing the aerodynamic efficiency of the compressor, the asymmetry of the flow field around the separation of the compressor, and the lack of consideration of intake distortion Problems such as flow field asymmetry, to achieve the effect of improving the stability margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

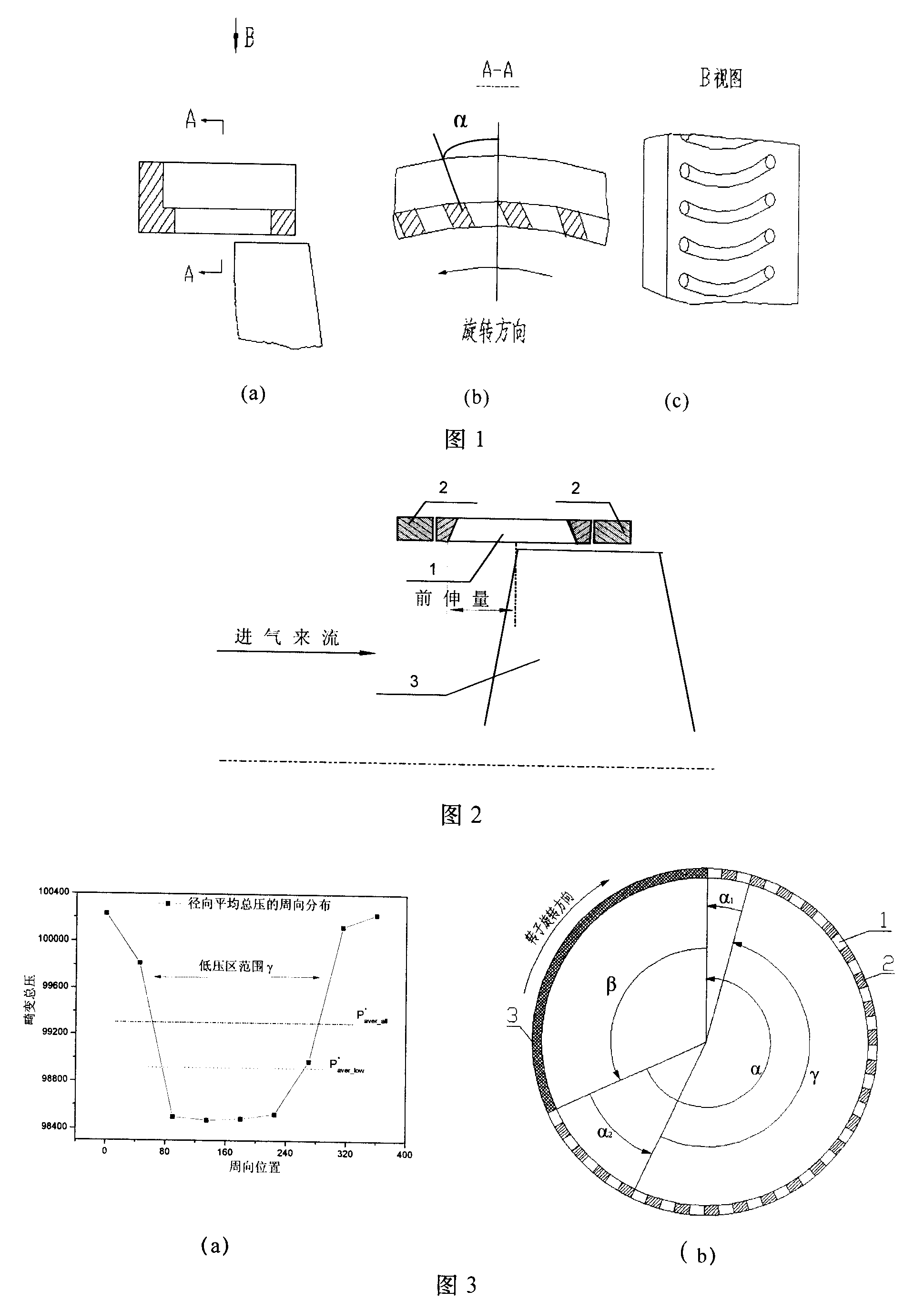

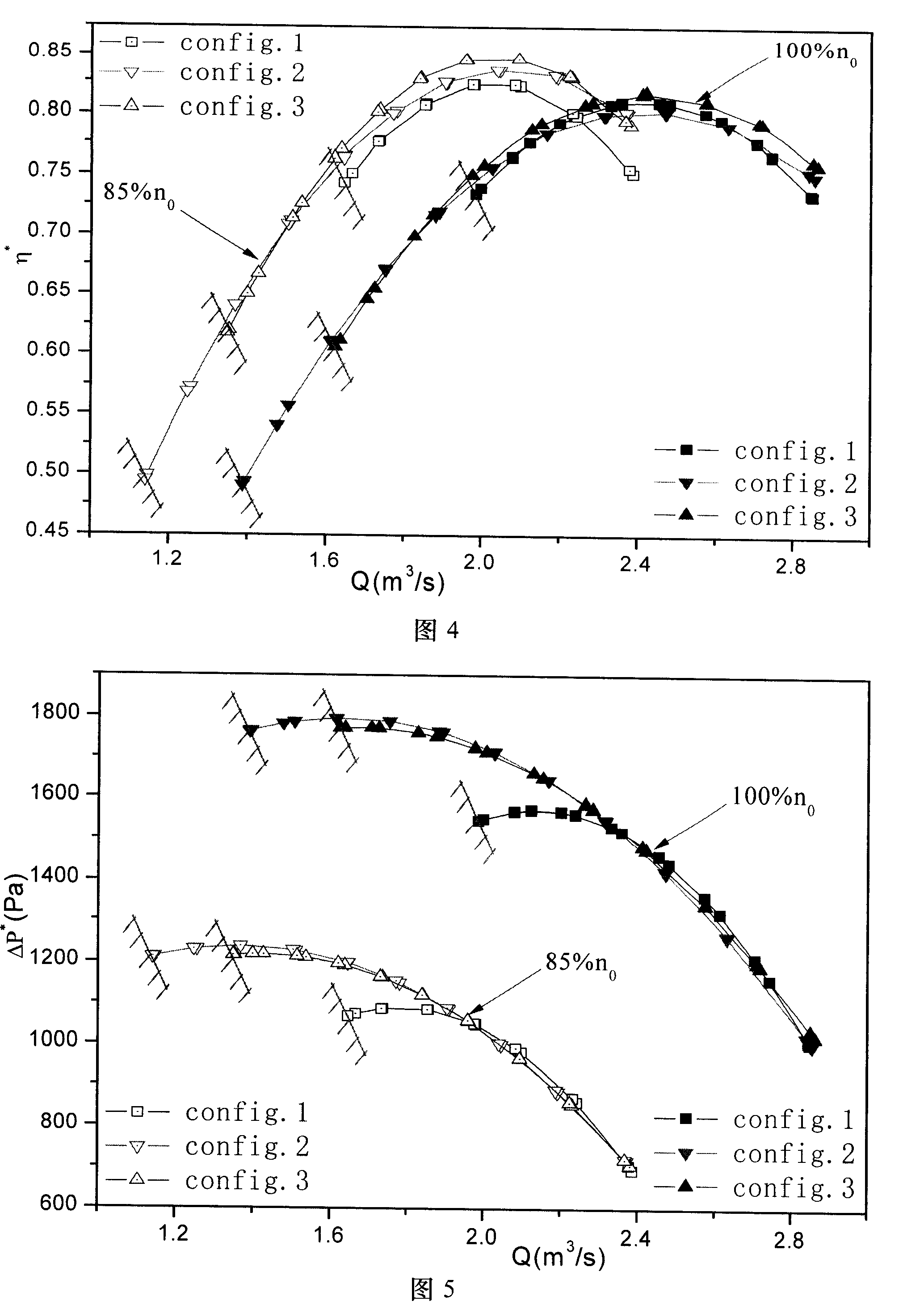

[0018] In order to describe the present invention more clearly, a typical embodiment of the unsteady generator for the asymmetric casing under severe inlet distortion of the present invention will be described below with reference to the accompanying drawings.

[0019] Fig. 2 is an axial sectional view of the unsteady generator of the asymmetric casing under serious inlet distortion according to the present invention. This asymmetric casing unsteady generator is composed of a processing ring and several distance adjusting rings. The processing ring is above the rotor blades of the compressor, and several distance adjustment rings are used to adjust the protruding amount of the crescent chute processing casing.

[0020] When using the processing case to improve the aerodynamic performance of the compressor, by adjusting the axial length of the distance adjusting ring, the processing ring moves forward or backward along the axial direction, thereby adjusting the amount of protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com