Gas compressor blade top plasma stability expanding system

A plasma and compressor technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as creepage phenomenon, complicated wiring, improper control of power supply voltage, etc., achieve good control effect and reduce flow loss, the effect of ease of installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

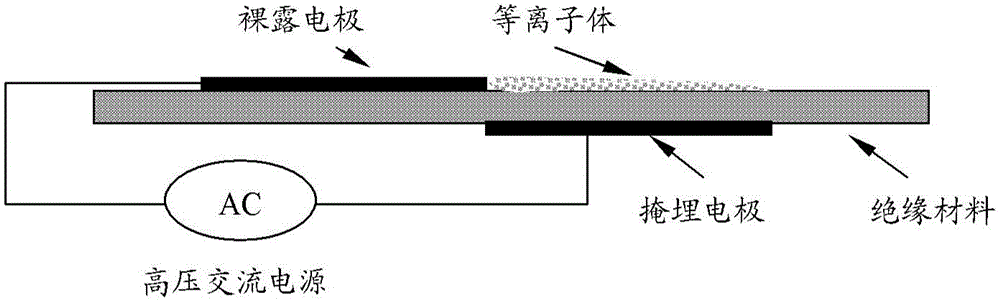

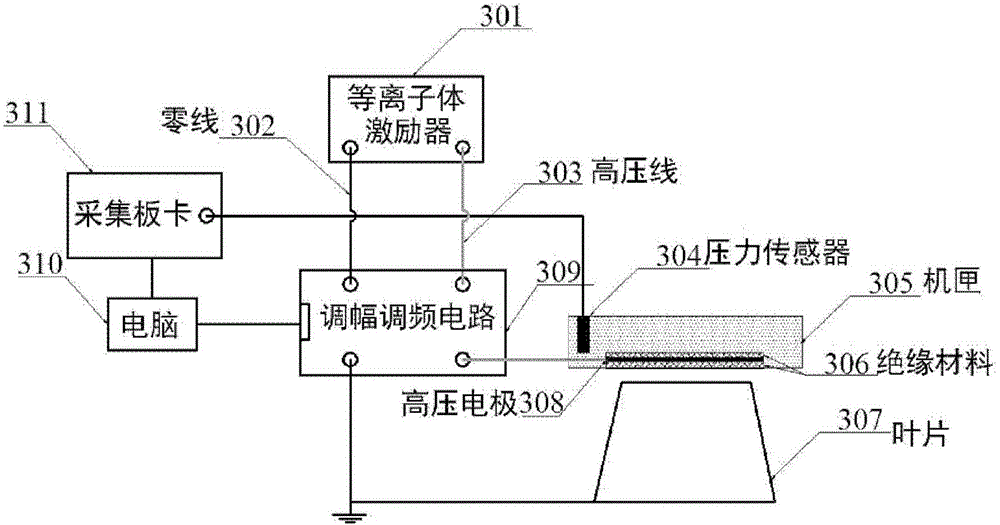

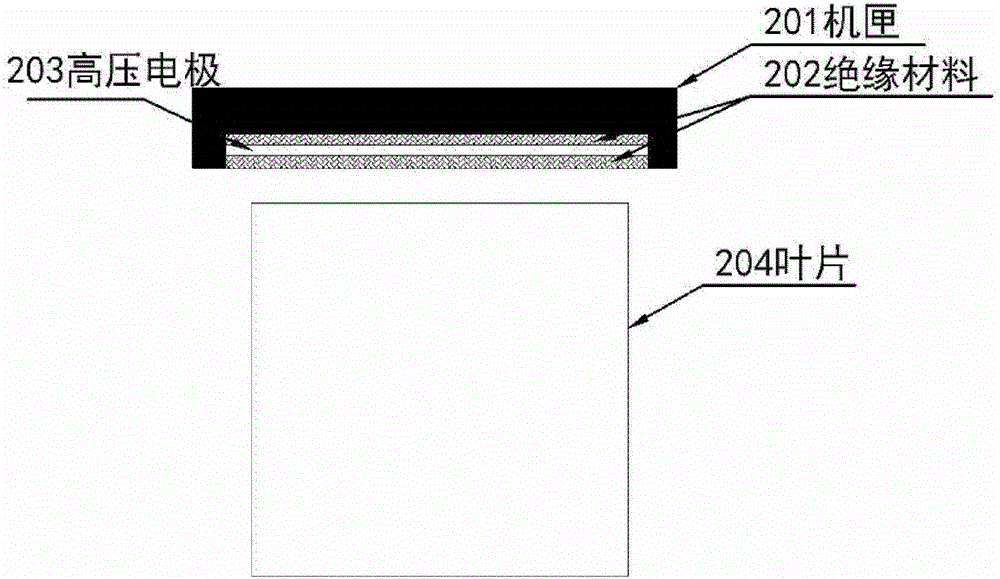

[0027] The plasma stability expansion system on the top of the compressor blade provided by the invention changes the traditional staggered arrangement of electrodes into an opposite arrangement, which can block the leakage flow and delay the occurrence of a stall when the working condition of the compressor changes. Such as figure 2 as shown, figure 2 A schematic diagram of a compressor blade top plasma stabilization system provided for the present invention, the system includes a plasma actuator 301, a neutral line 302, a high voltage line 303, a pressure sensor 304, a casing 305 of a turbomachinery, an insulating material 306, and a compressor Blade 307, high voltage electrode 308, AM / FM circuit 309, computer 310 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com