Boron carbide shielding assembly

A technology of boron carbide and components, applied in the direction of shielding, reactors, reducing greenhouse gases, etc., can solve the problems of design life limit, complex structure, etc., and achieve the effect of alleviating the stress state, increasing wear resistance, and preventing self-welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

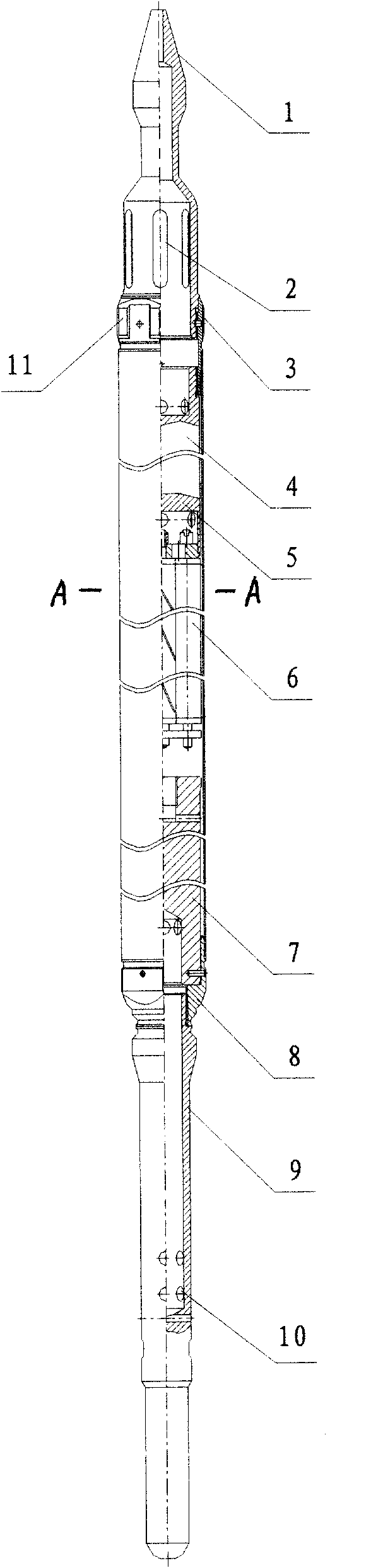

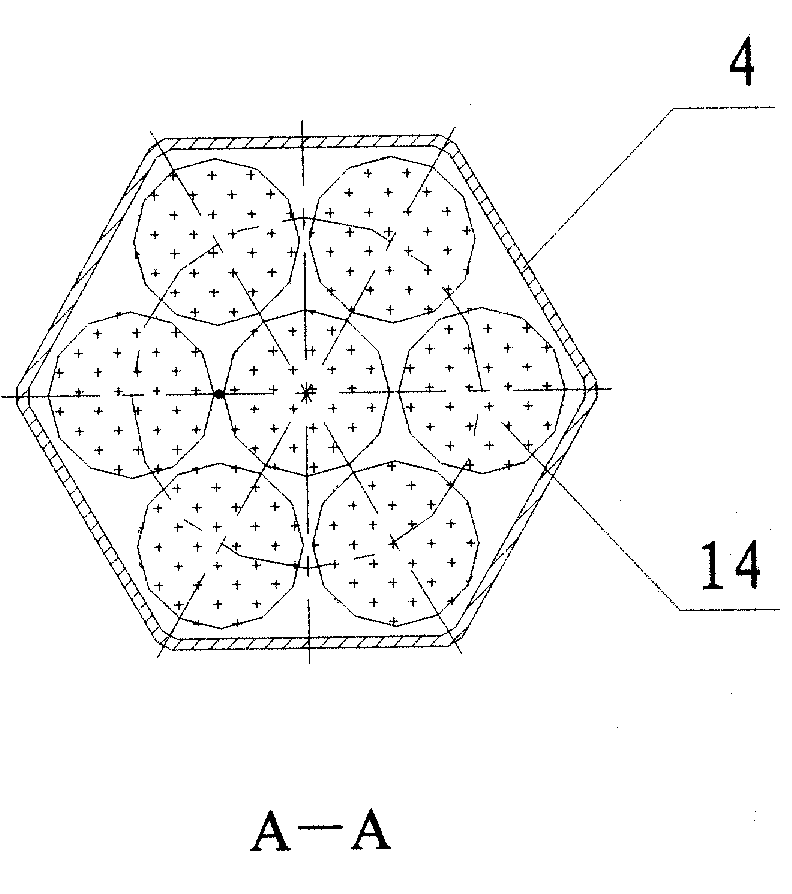

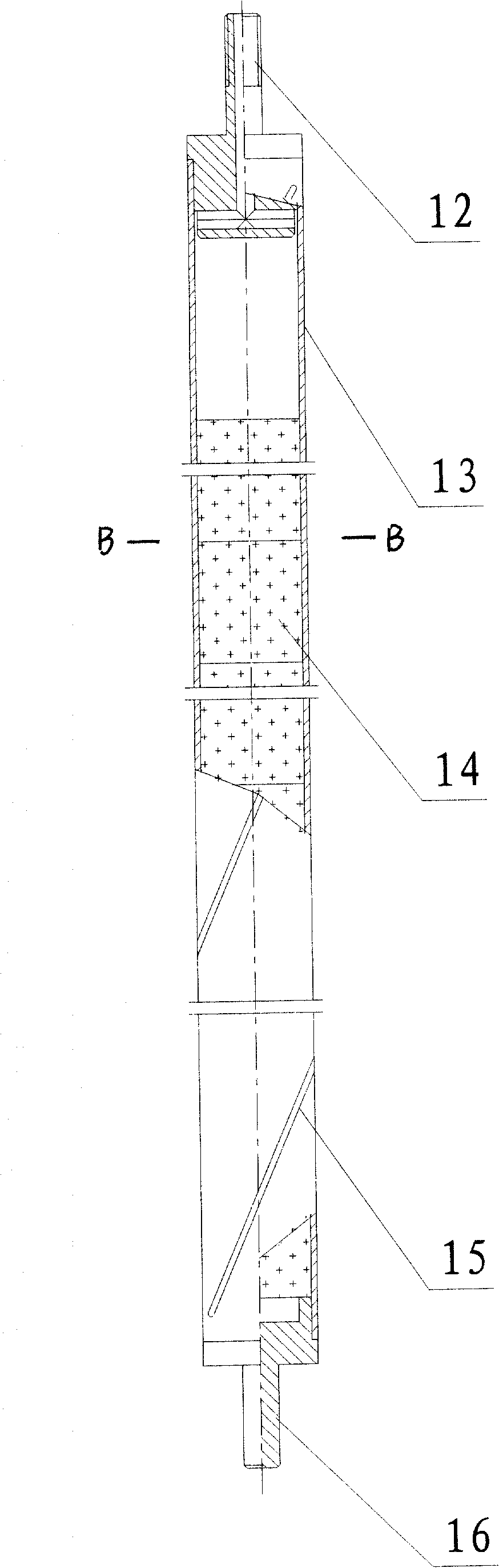

[0013] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0014] The boron carbide shielding assembly described in this embodiment is arranged on the periphery of the reflector assembly of the sodium-cooled fast reactor, and is arranged in 4 layers, with a total of 230 boxes. Allow to cool. The basic design and operating parameters are shown in Table 1.

[0015] Table 1 Basic parameters of boron carbide shielding components

[0016] parameter name

value

shielding material

boron carbide

10 B enrichment (%)

19.8 (natural)

B in a box of components 4 C weight (kg)

2.4

Weight of a box of components (kg)

~32

Working life of components under rated power (effective days)

(1) The first floor

1440

(2) The second floor

1680

(3) The third floor

1920

(4) The fourth floor

2240

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com