Thermoplastic elastomer and thermoplastic elastomer composition

A technology of thermoplastic elastomers and elastomeric polymers, applied in the field of thermoplastic elastomers and thermoplastic elastomer compositions, can solve the problems of unsuitable oil resistance and poor oil resistance, and achieve excellent cycle performance and excellent compression set , high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~1-4 and comparative example 1-1~1-3

[0254] First, into a pressurized kneader set at 180° C., epoxidized natural rubber (ENR-50, epoxidation rate 50%, manufactured by Mallesiagum Bureau (MRB) was charged in parts by mass shown in Table 1 below. ) and an anti-aging agent (Irganox 1010, manufactured by Chiba Specialty Chemical Corporation) were kneaded for 5 minutes.

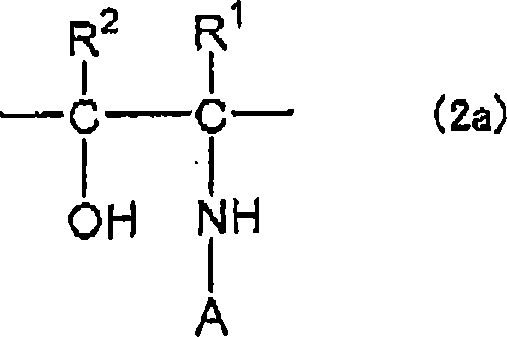

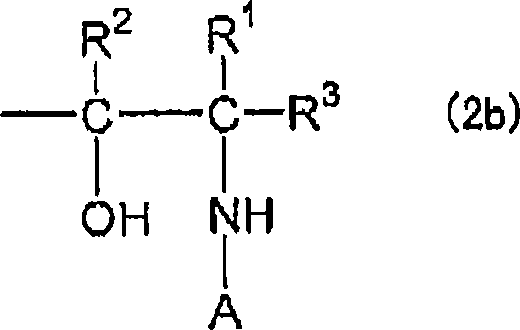

[0255] Then, 3-amino-1,2,4-triazole (manufactured by ATA, Nippon Kabito Co., Ltd.), 2-aminothiazole (manufactured by Wako Pure Chemical Industries, Ltd.), -4-hydroxymethylimidazole (manufactured by Nippon Synthetic Chemicals Co., Ltd.), 4-aminopyridine (manufactured by Hiroei Chemical Co., Ltd.), diethylenetriamine (manufactured by Tokyo Chemical Industry Co., Ltd.), 3-mercaptotriazole (manufactured by Otsuka Chemical Co., Ltd. ) or 2-mercaptoimidazole (manufactured by Otsuka Chemical Co., Ltd.), kneaded for 10 minutes, and reacted to prepare a thermoplastic elastomer composition containing a thermoplastic elastomer. By performing IR analysis, it ca...

Embodiment 1-5 and 1-6

[0278] First, into a pressurized kneader set at 180° C., an acrylic rubber (AR54, manufactured by Nippon Zeon Co., Ltd.) having an epoxy structure and an anti-aging agent (Irganox 1010, Ciba Specialty Co., Ltd.) were charged in parts by mass shown in Table 2 below. ・Chemicaruzu Co., Ltd.), kneaded for 5 minutes.

[0279] Then, 3-amino-1,2,4-triazole (manufactured by ATA, Nippon Kabito Co., Ltd.) was added in parts by mass shown in Table 2 below, and kneaded for 10 minutes to react, thereby preparing a compound containing thermoplastic Elastomer thermoplastic elastomer composition. By performing IR analysis, it can be confirmed that the thermoplastic elastomer contains an epoxy-containing structure, a hydroxyl group, and a nitrogen-containing heterocycle.

[0280] For each of the thermoplastic elastomer compositions obtained in Examples 1-5 and 1-6, JIS-A hardness, tensile properties, compression set, and oil resistance were measured according to the methods described later, an...

Embodiment 2-1 and comparative example 2-1

[0288] First, epoxidized natural rubber (ENR-50, epoxidation rate 50%, manufactured by Mallesiagum Bureau (MRB) ) and an anti-aging agent (Irganox 1010, manufactured by Chiba Specialty Chemical Corporation) were kneaded for 5 minutes.

[0289] Then, polyethyleneimine (Epomin SP-200, weight-average molecular weight 10000, manufactured by Nippon Shokubai Co., Ltd.) or diethylenetriamine (made by Tokyo Chemical Industry Co., Ltd.) was added in parts by mass shown in Table 3 below, and mixed It was kneaded for 10 minutes and reacted to prepare a thermoplastic elastomer composition containing a thermoplastic elastomer. By performing IR analysis, it can be confirmed that the thermoplastic elastomer contains an epoxy structure and a hydroxyl group and a primary amino group and / or a secondary amino group.

[0290] For each of the thermoplastic elastomer compositions obtained in Example 2-1 and Comparative Example 2-1, JIS-A hardness, tensile properties, compression set, and oil resis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com