Method for preparing nano bismuth oxide

A technology of bismuth oxide and bismuth salt, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds and other directions, can solve the problems of high production cost, large consumption of organic solvents and surfactants, etc., and achieves low production cost, convenient operation, Good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

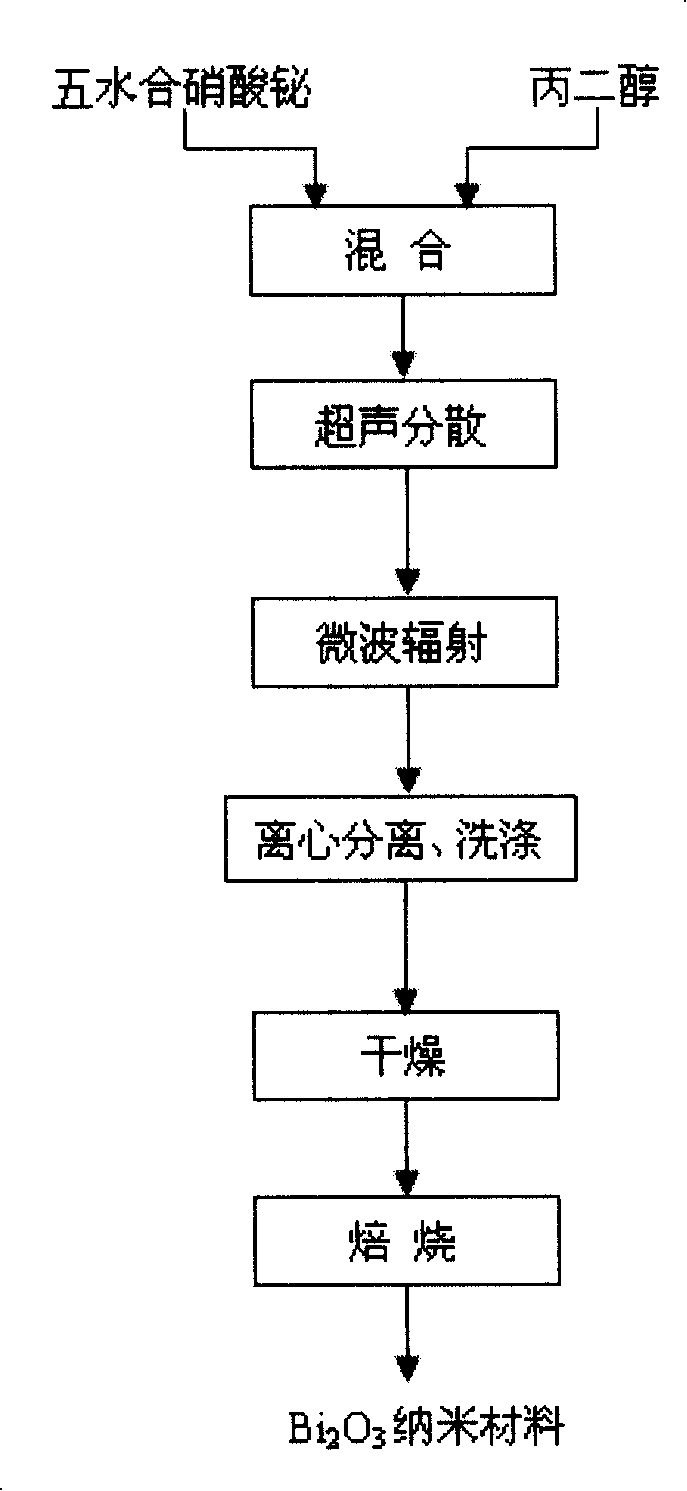

[0024] Embodiment 1 The method for preparing bismuth oxide

[0025] Accurately weigh 3.65g of bismuth nitrate pentahydrate, measure 50ml of propylene glycol, mix the two in a beaker, and ultrasonically disperse for 30min until the bismuth nitrate is completely dissolved. Then above-mentioned mixed solution is transferred in the 250ml round-bottomed flask, is placed in the microwave oven that is connected with reflux device and reacts, microwave power is 360W, microwave radiation 6 minutes (each 2 minutes, interval 1 minute, totally 3 times). After the reaction, the product was collected, centrifuged, and washed three times with deionized water and absolute ethanol. Dry at 80°C for 6h. Calcined at 600°C for 2h to obtain bismuth oxide product.

[0026] The preparation process of this method is shown in figure 1 .

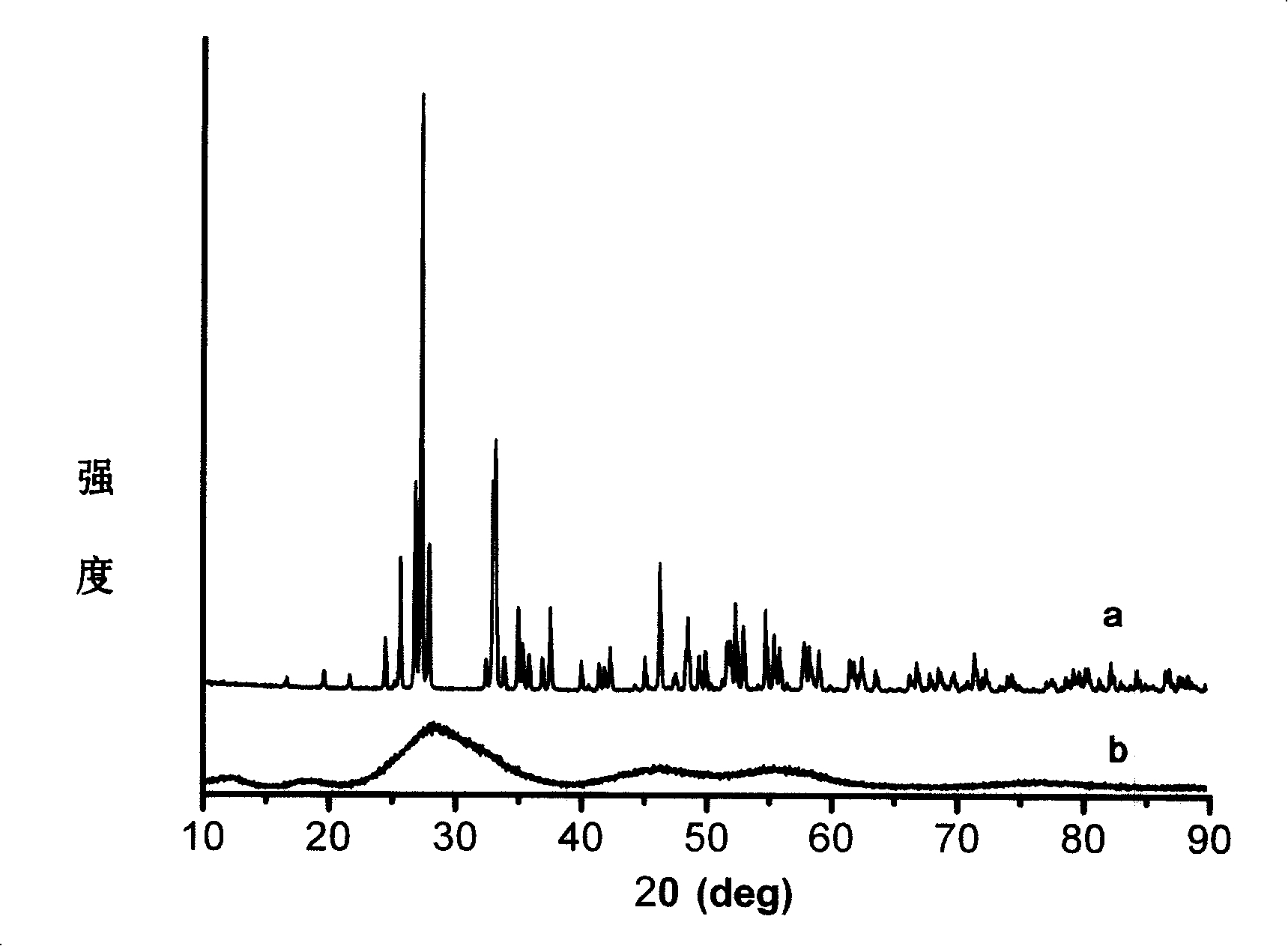

[0027] The XRD spectrum pattern of the resulting product is shown in figure 2 . It can be seen from b that most of the microwave products are amorphous and no...

Embodiment 2

[0029] Accurately weigh 1.66g of bismuth acetate, measure 50ml of ethylene glycol, mix the two in a beaker, and ultrasonically disperse for 20min until the bismuth acetate is completely dissolved. Then above-mentioned mixed solution is transferred in the 250ml round-bottomed flask, is placed in the microwave oven that is connected with reflux device and reacts, and microwave power is 180W, microwave radiation 20 minutes (every 4 minutes, intermediate interval 2 minutes, totally 5 times). After the reaction, the product was collected, centrifuged, and washed three times with deionized water and absolute ethanol. Dry at 60°C for 12h. Calcined at 550°C for 2h to obtain bismuth oxide product.

[0030] The XRD spectrum of the resulting product and figure 2 Basically the same.

Embodiment 3

[0032] Accurately weigh 1.66g of bismuth acetate, measure 50ml of propylene glycol, mix the two in a beaker, and ultrasonically disperse for 20min until the bismuth acetate is completely dissolved. Then above-mentioned mixed solution is transferred in the 250ml round-bottomed flask, is placed in the microwave oven that is connected with reflux device and reacts, microwave power is 540W, microwave radiation 16 minutes (every 4 minutes, interval 2 minutes, totally 4 times). After the reaction, the product was collected, centrifuged, and washed three times with deionized water and absolute ethanol. Dry at 60°C for 12h. Calcined at 650°C for 2h to obtain bismuth oxide product.

[0033] The XRD spectrum of the resulting product and figure 2 Basically the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com