Method for synthesizing high-crystallinity ZSM-5 molecular sieve without organic template

An organic template agent and high crystallinity technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of high energy consumption, achieve high single-pot yield, and be environmentally friendly , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

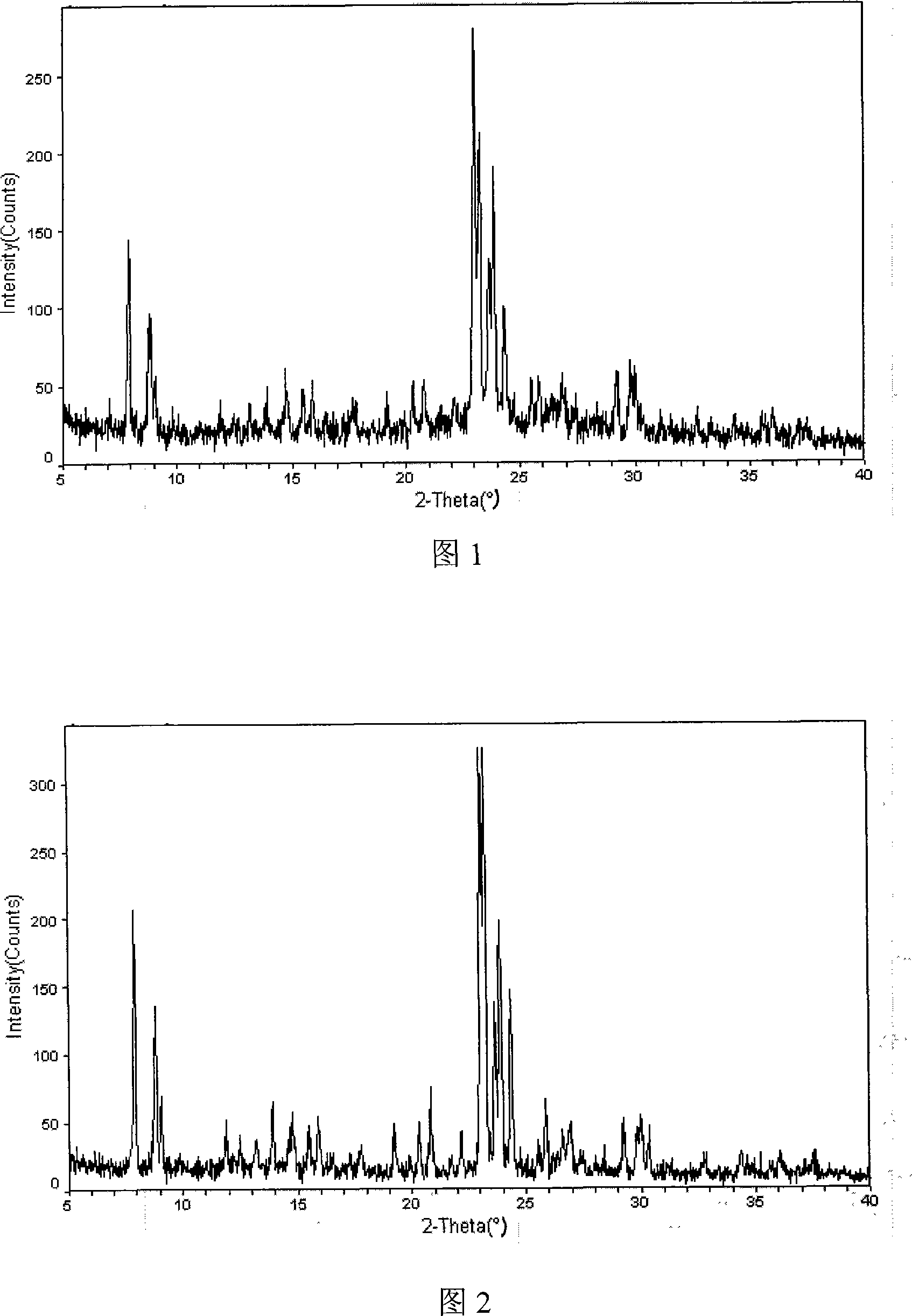

[0026] 0.480 gram of sodium hydroxide is dissolved in 28.69 gram of water, after stirring until clarification, add 0.796 gram of sodium aluminate (Al 2 o 3 41.0wt%, Na 2 O2 4.9wt%, H 2 (24.1 wt%) and 3.846 grams of solid silica gel (100-200 mesh), stirred for 1 hour to obtain a uniform gel. The gel was transferred to a 100mL polytetrafluoroethylene-lined stainless steel crystallization kettle, sealed and then crystallized with stirring at 190°C for 12 hours. After suction filtration, washing and drying, 6.72g of solid product was obtained.

[0027] The solid product was analyzed by X-ray diffraction to be ZSM-5 molecular sieve (see Figure 1), with a relative crystallinity of 102%.

[0028] In the present embodiment, the mol ratio between each component of reaction mixture is as follows:

[0029] SiO 2 :Al 2 o 3 =20:1, Na 2 O: SiO 2 =0.14:1, H 2 O: SiO 2 =25:1.

Embodiment 2

[0035] 5.457 grams of sodium silicate (SiO 2 21.15wt%, Na 2 O2 1.82wt%, H 2 (257.03wt%) was dissolved in 34.30 grams of water, and stirred until clarified to obtain solution A; in another beaker, 0.796 grams of sodium aluminate (Al 2 o 3 41.0wt%, Na 2 O2 4.9wt%, H 2(24.1wt%) was dissolved in 34.30 g of water, and stirred until clear to obtain solution B. Quickly add solution B to solution A at room temperature, then add 8.462 g of solid silica gel (100-200 mesh) while stirring, and continue stirring for 1 hour after the addition to obtain a uniform gel. The gel was transferred to a 100mL polytetrafluoroethylene-lined stainless steel crystallization kettle, sealed and then crystallized with stirring at 180°C for 72 hours. After suction filtration, washing, and drying, 5.44 g of a solid product was obtained.

[0036] The solid product was analyzed by X-ray diffraction to be ZSM-5 molecular sieve with a relative crystallinity of 114%.

[0037] In the present embodiment, th...

Embodiment 3

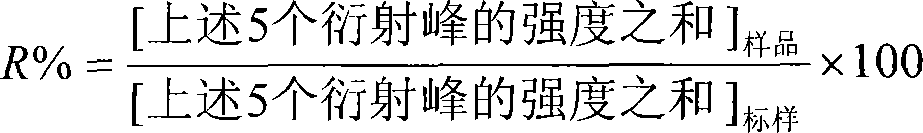

[0040] 4.608 gram of sodium hydroxide is dissolved in 71.46 gram of water, after stirring until clarification, add 1.592 gram of sodium aluminate (Al 2 o 3 41.0wt%, Na 2 O2 4.9wt%, H 2 (24.1 wt%) and 19.23 g of solid silica gel (100-200 mesh), stirred for 1 hour to obtain a uniform gel. The gel was transferred to a 100mL polytetrafluoroethylene-lined stainless steel crystallization kettle, sealed and then crystallized with stirring at 190°C for 24 hours. After suction filtration, washing and drying, 9.08g of solid product was obtained.

[0041] The solid product was analyzed by X-ray diffraction to be ZSM-5 molecular sieve with a relative crystallinity of 172%.

[0042] In the present embodiment, the mol ratio between each component of reaction mixture is as follows:

[0043] SiO 2 :Al 2 o 3 =50:1, Na 2 O: SiO 2 =0.2:1, H 2 O: SiO 2 =12.5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com