Auxiliary focusing mechanism of laser marking machine and use method thereof

A technology that assists focusing and marking machines. It is applied to laser welding equipment, welding equipment, metal processing equipment, etc. It can solve the problems of affecting the marking effect, invisible laser beam, and inconvenient workpiece alignment, and meets the requirements of experience and skills. Lowering, best marking effect, easy fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

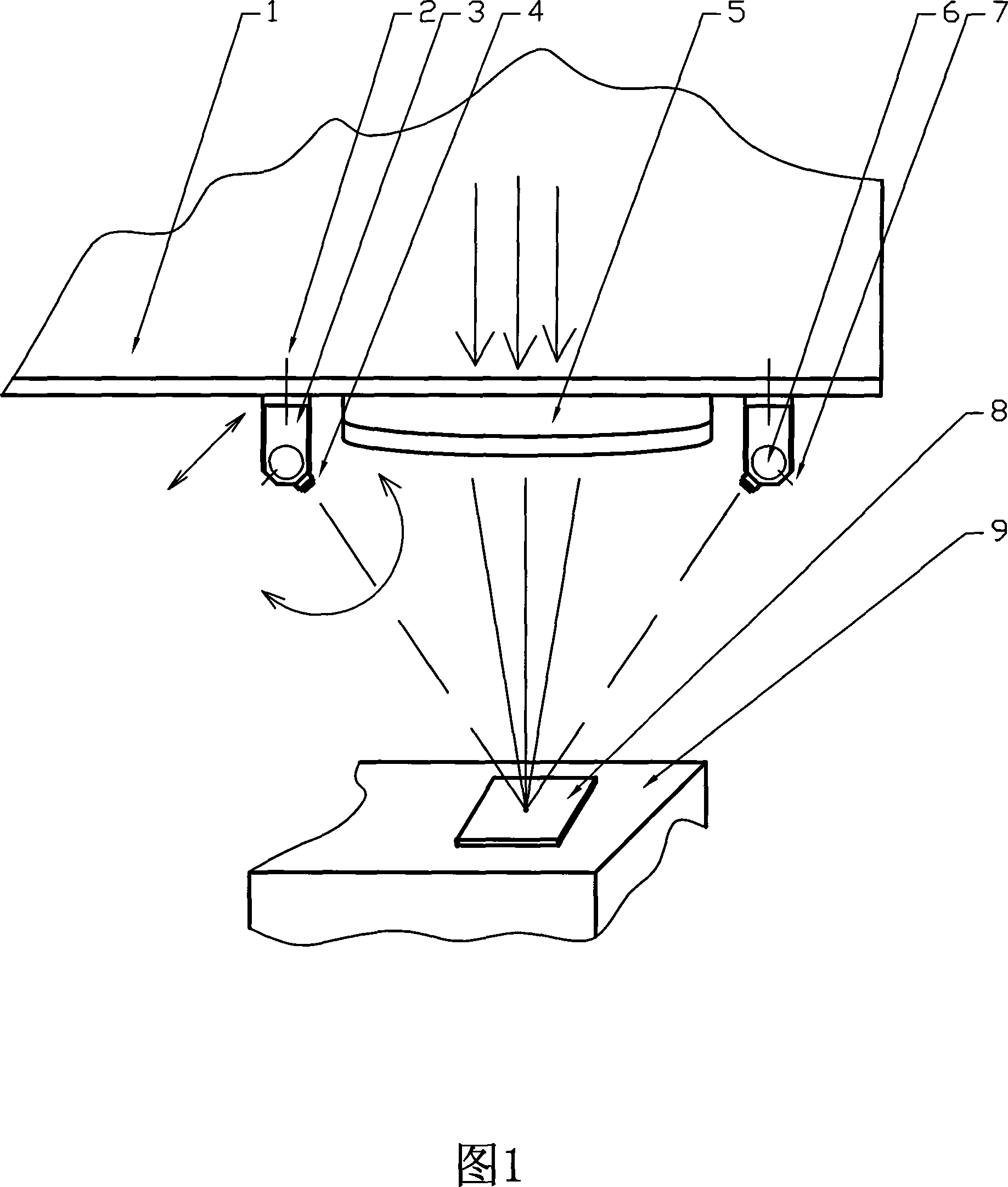

[0014] Figure 1 shows an embodiment of the auxiliary focusing device of the laser marking machine. The laser marking machine includes a laser generator, a focusing mirror 5 fixed on the focusing mirror base 1, a workbench 9 for placing a workpiece 8, and two light pens. Bracket 3, two light pens 4 that can emit visible parallel light beams, and the two light pens 4 are externally connected to a controllable power supply. In this embodiment, the focusing lens base 1 on which the focusing lens 5 is installed is fixed, and the workbench 9 on which the workpiece 8 is placed can be translated up and down.

[0015] Focusing mirror base 1 has threaded holes on both sides of focusing mirror 5, and the threaded holes on both sides are in line with the center of focusing mirror 5. There is a waist-shaped hole on the top of the second bracket 3, and the translation locking screw 2 passes through the waist-shaped hole to connect to focusing mirror base 1. The threaded hole, the support 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com