Golf club head

A golf club head and club head technology, applied in golf balls, golf clubs, rackets, etc., can solve the problems of poor magnesium alloy strength, poor bonding effect, insufficient strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Give two embodiments now and cooperate accompanying drawing to illustrate as follows:

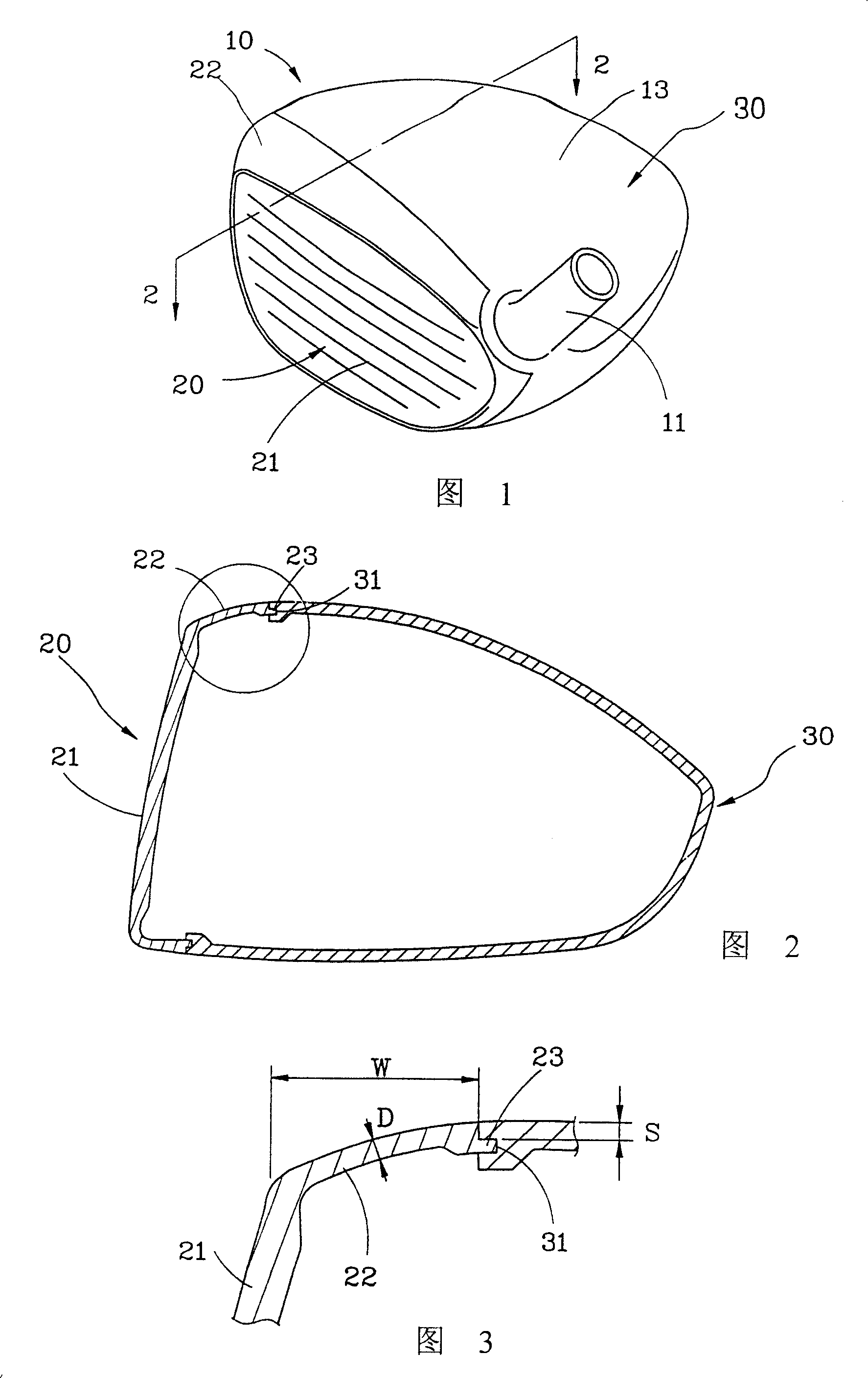

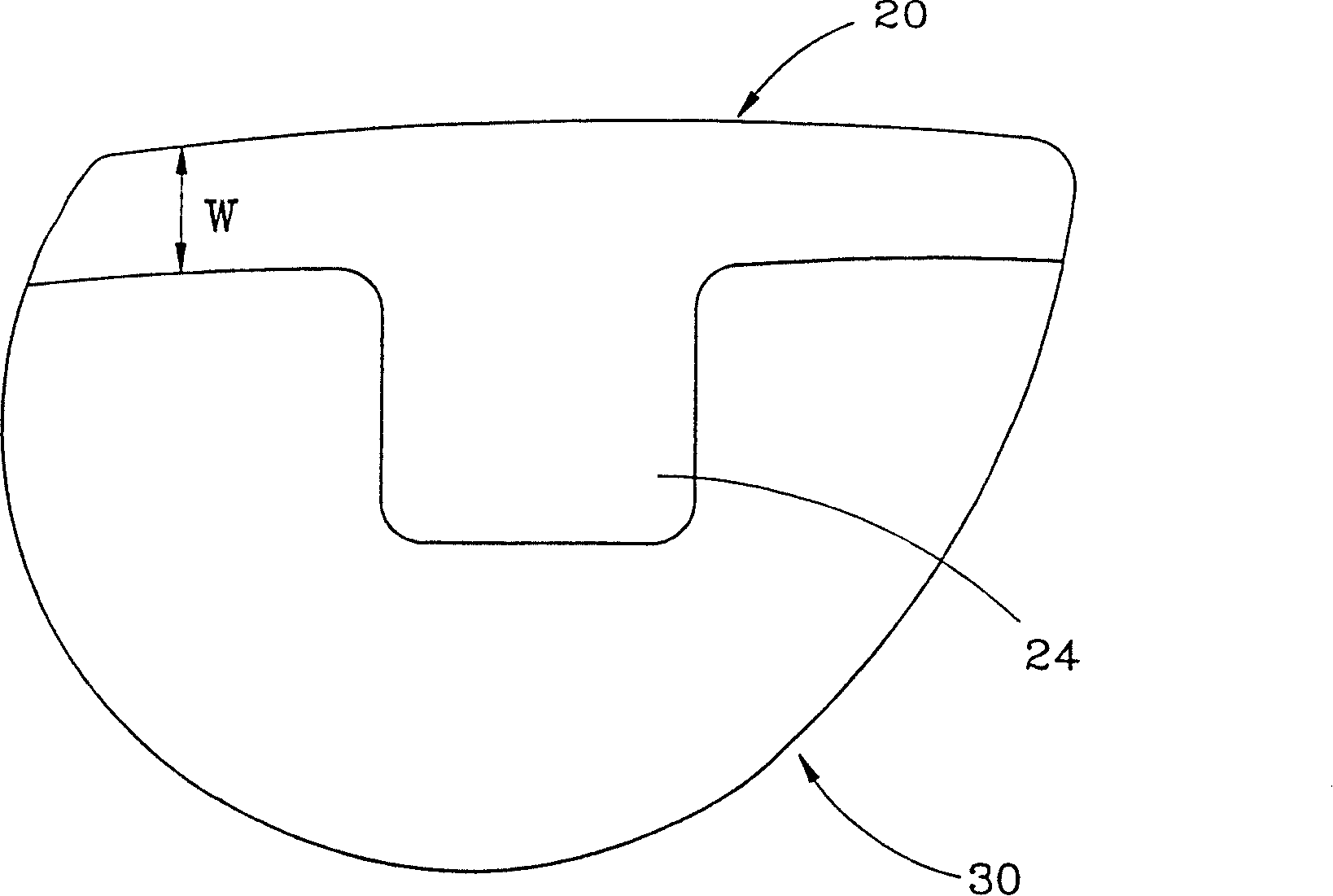

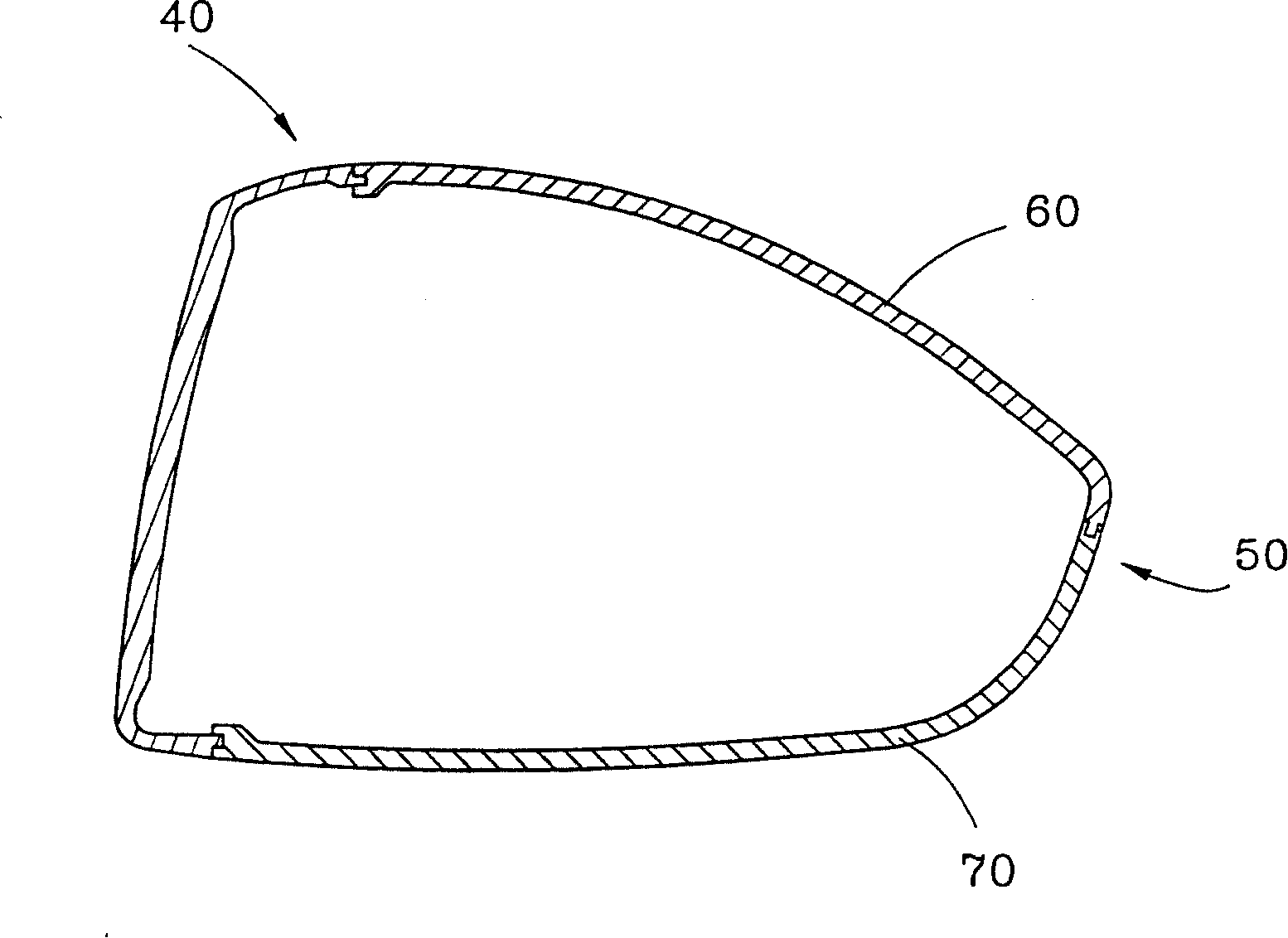

[0016] Figure 1~ Figure 4 As shown, the golf club head 10 of the first embodiment of the present invention is composed of a front side shell 20 and a rear side shell 30, wherein:

[0017] The front shell 20 is made of titanium alloy or stainless steel or hemp aging steel and other metals with good elasticity. It is cup-shaped, and there is an embedding part 23 at the outer end of the wall part 22. The distance W between the wall part 22 from the hitting surface 21 to the outer end of the wall part is equal to or greater than 8 cm, and the thickness D of the wall part 22 is equal to or less than 2 cm. W of the present embodiment is 10 centimeters, and D is 1.5 centimeters.

[0018] The rear shell 30 is made of light metals with light specific gravity such as magnesium alloy or aluminum alloy. The connecting parts 23 engage with each other. In this embodiment, the embedding portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com