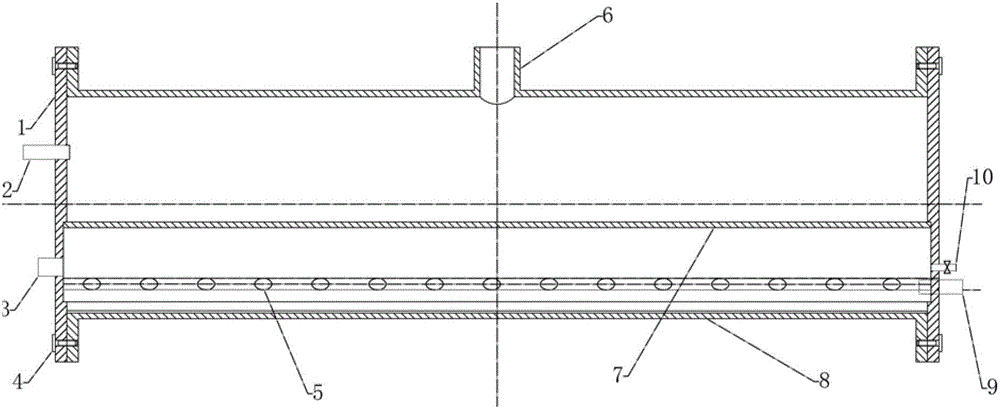

Tangential casing built-in aeration photo-bioreactor applicable to micro algae high-efficiency culture

A photobioreactor, high-efficiency technology, applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, enzymology/microbiology device, etc., can solve the problem of untimely replenishment and gas-liquid mixing effect Poor, restricting the scale of training and other issues, to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

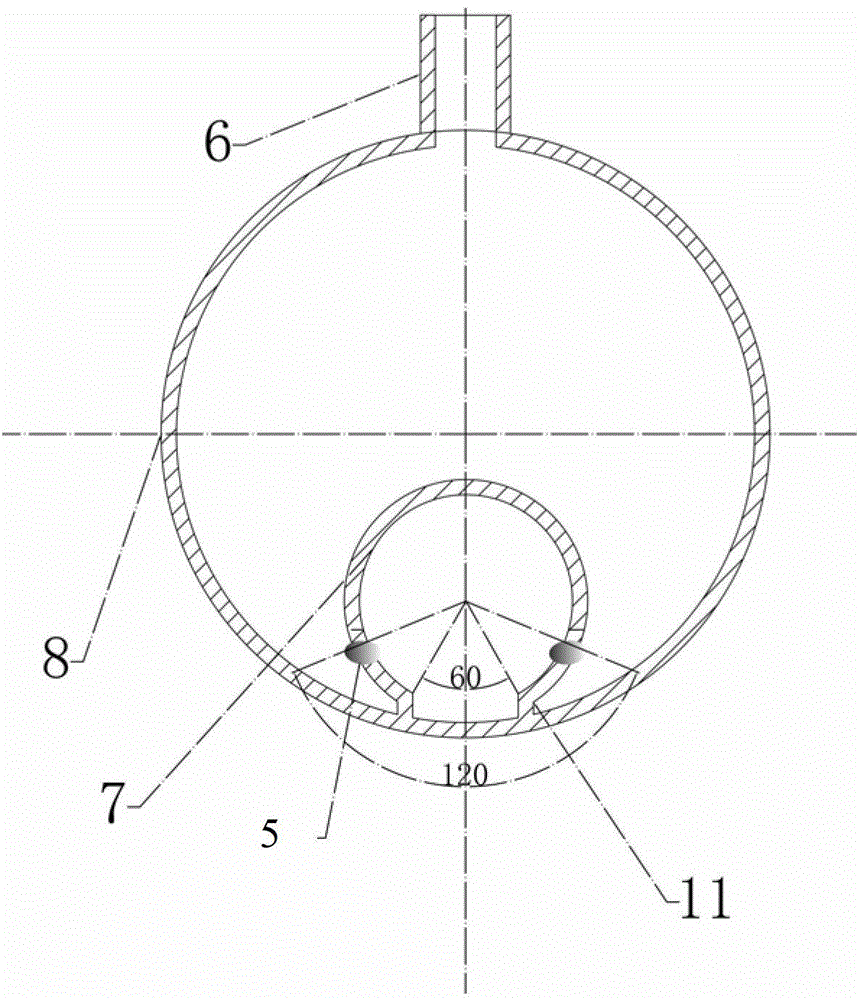

[0033] Focusing on the limitations of tubular photobioreactors, Sato et al. based on the tube type, arranged a coaxial light-tight inner tube (outer diameter 200 mm) in a large-diameter light tube (inner diameter 250 mm), and the backlight bottom of the outer tube There is a row of aeration holes, relying on the aeration flow to drive the algae liquid between the casings to circulate in the circumferential direction (Sato, T., D. Yamada, and S. Hirabayashi, Development of virtual photobioreactor for microalgae culture considering turbulent flow and flashing light effect. Energy Conversion and Management, 2010.51(6): p.1196-1201). It can be seen from the analysis that the above design is beneficial to promote CO 2 Diffusion in algae liquid, exchange and removal of dissolved oxygen in algae liquid, circulation and mixing of algae liquid and control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com