Sodium-sodium heat converter

A technology of heat exchanger and heat exchange tube bundle, applied in the field of reactor emergency cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

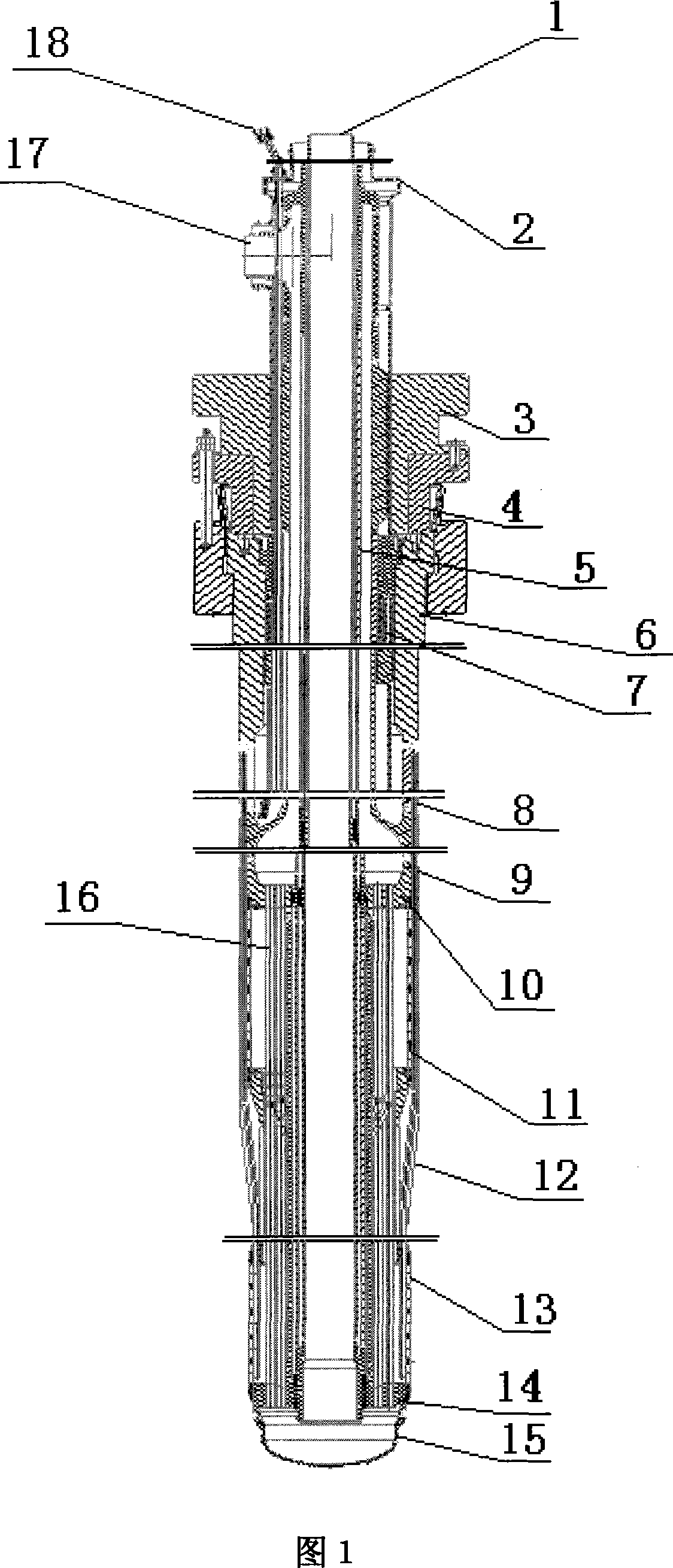

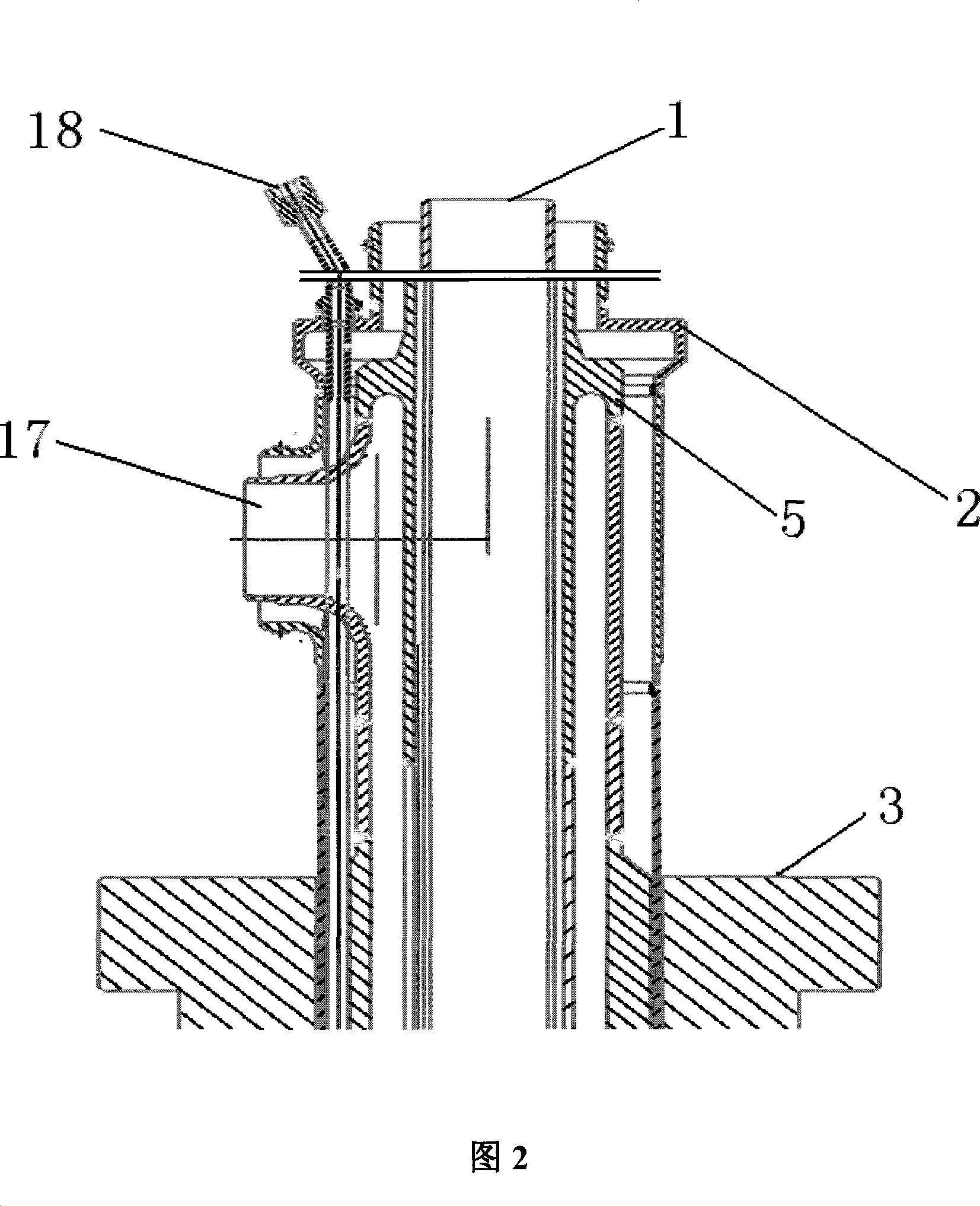

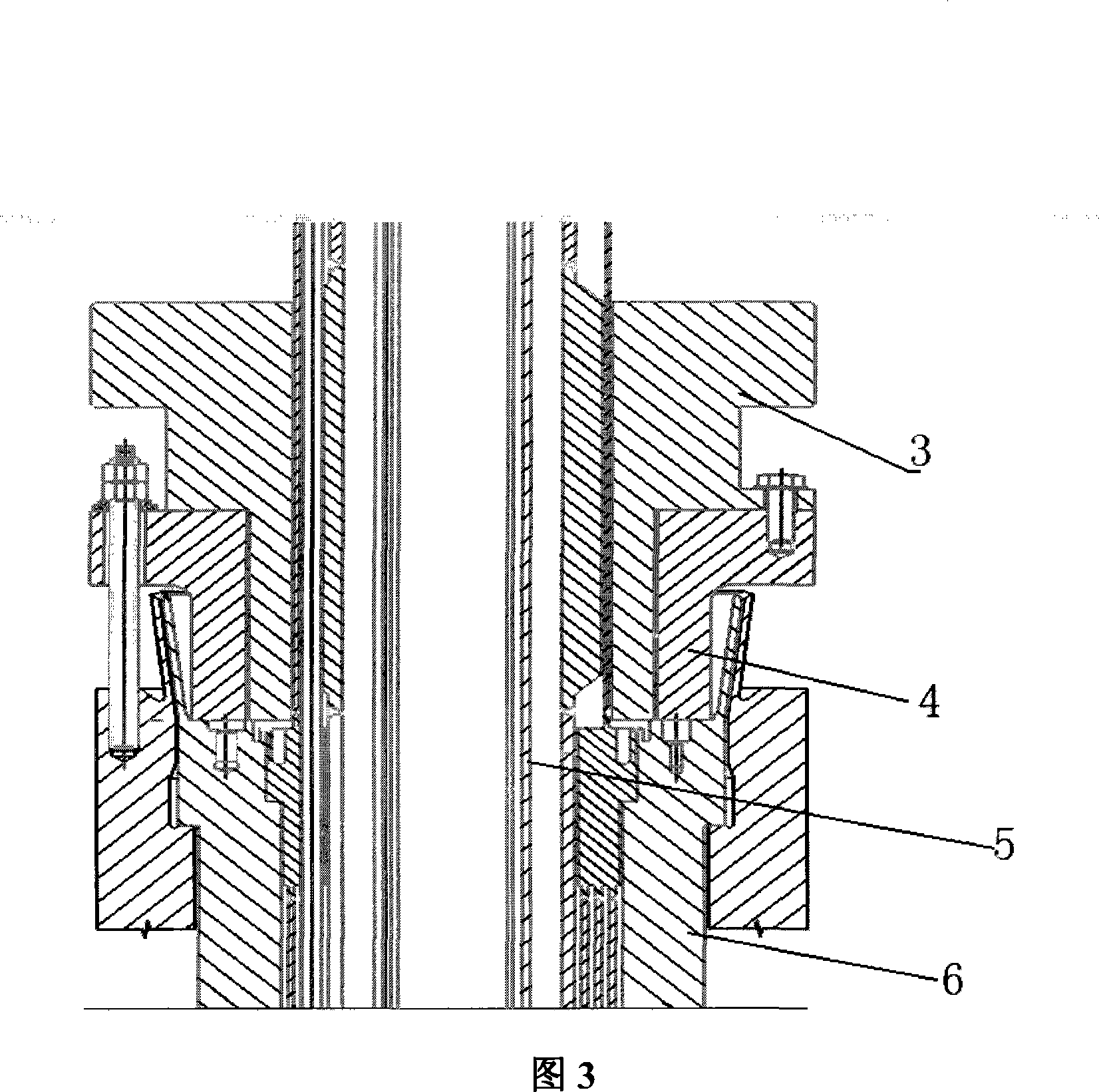

[0014] In the following, the technical solution of the present invention will be further described by taking an immersed sodium-sodium heat exchanger used in a fast reactor as an example in conjunction with the accompanying drawings. Table 1 is its technical characteristics and parameters.

[0015] Table 1 Technical characteristics and parameters of independent heat exchanger

[0016] shell side

Monitor

A operating conditions (rated cooling conditions)

Flow(kg / s)

5.8

2.93

516

373

Outlet temperature (℃)

444

514

Inlet pressure (MPa)

0.6

0.6

Heat flow (MW)

0.525

0.525

B heat exchanger parameters

[0017] Heat transfer area (m 2 )

5.2

Design pressure (MPa)

0.6

Design temperature (℃)

550

Heat excha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com