Automatic disconnection device of sewing machine

A technology of automatic cutting and cutting devices, which is applied to sewing machine components, sewing machine thread cutting mechanisms, sewing equipment, etc., can solve the problems of brake damage, power consumption, damage, etc., and achieve the reduction of the overall structure volume and the reduction of the overall structure volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the structure, characteristics and other purposes of the present invention, the following preferred embodiments are described in detail with accompanying drawings, but the embodiments described in this illustration are for illustration purposes only, not for patent application The only limitation on .

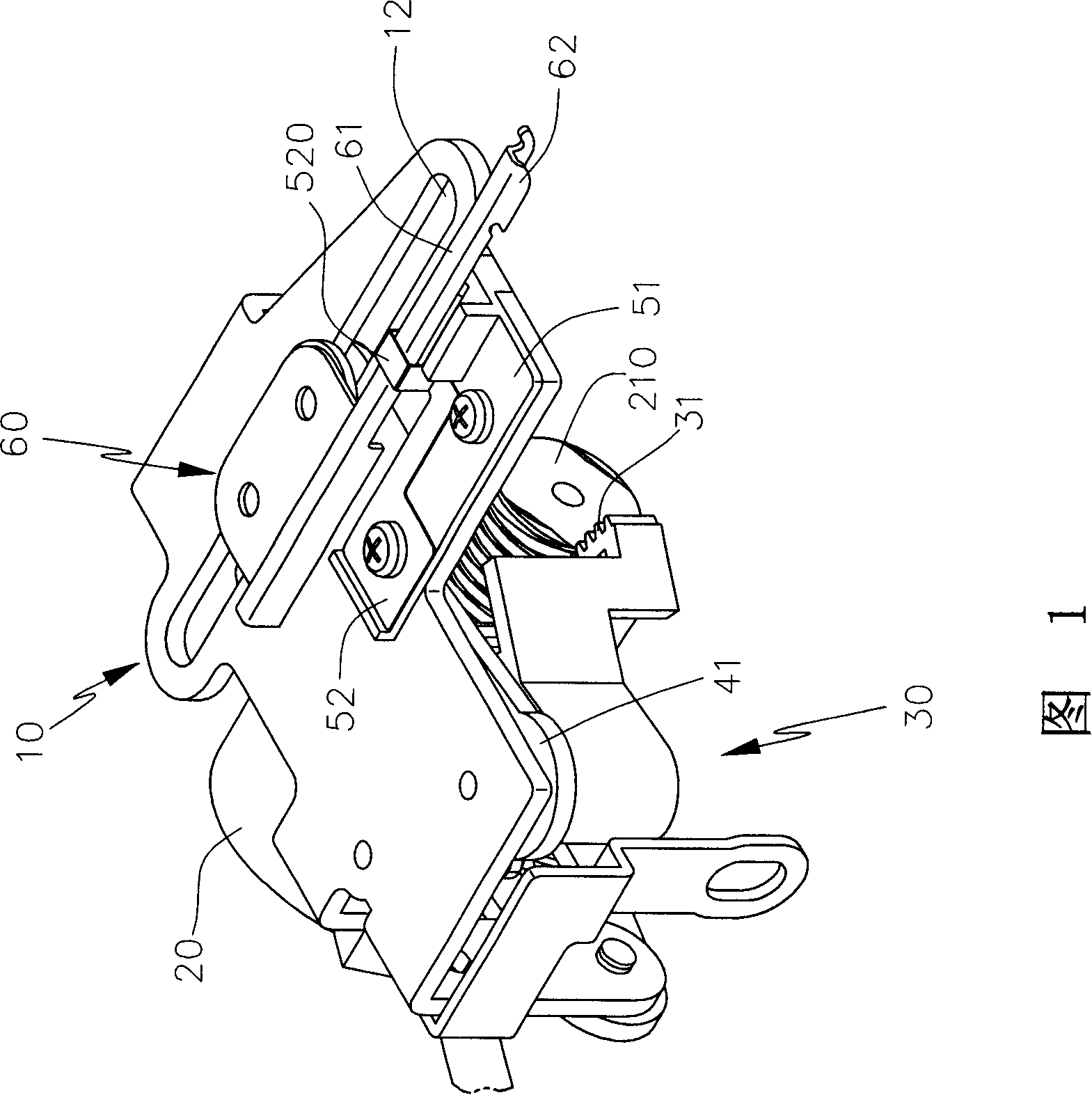

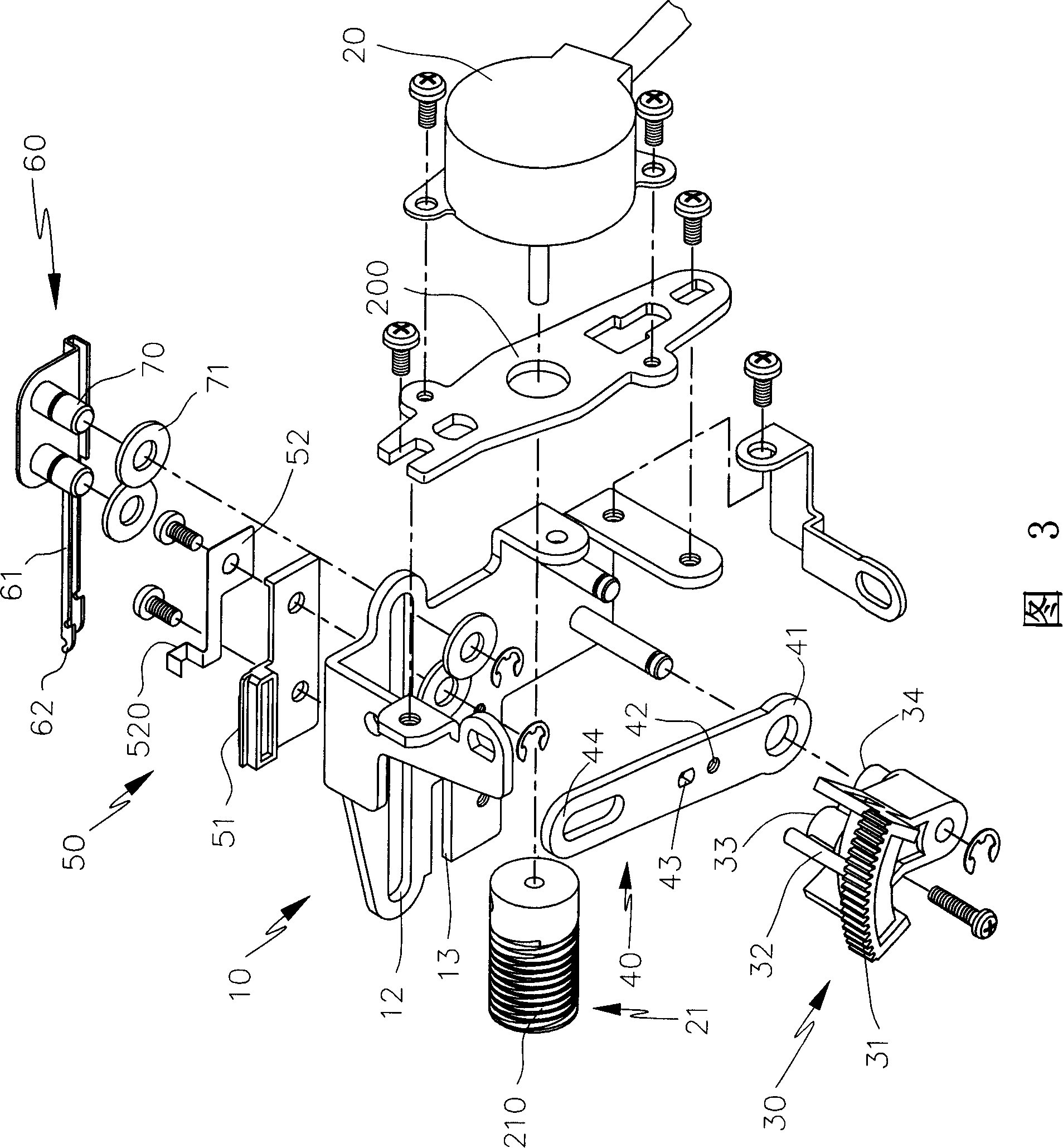

[0036] Please refer to FIG. 1-FIG. 3, the cutting device of the present invention mainly has a main body 10, and the main body 10 is provided with a driving part 21 driven by the driving part 20, and the driving part 21 engages a driven part 30. , the follower 30 coaxially drives a link 40, and one end of the link 40 matches the knife seat 50 of the main body 10 to jointly link and clamp a hook line body 60, and the knife on the knife seat 50 The body 51 performs tangential operation and moves in the direction of the fixed guide structure, so as to achieve overall high stability, high safety and high rationality in structural design and fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com